3095293

Male Union

Cummins®

IN STOCK

More than 10 are currently available

Ships within 1 business day

This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

The Male Union Fitting 3095293, manufactured by Cummins, is a component designed for use in commercial truck operations. Cummins, a well-established name in the commercial vehicle industry, produces a range of parts and systems that contribute to the efficiency and reliability of heavy-duty trucks. This Cummins part plays a role in the fluid systems of commercial trucks by facilitating secure and efficient connections.

Basic Concepts of Male Union Fittings

A Male Union Fitting is a type of pipe fitting used to connect two sections of pipe or tubing in fluid systems. It consists of a male threaded end that screws into a female counterpart, often secured with a union nut to allow for easy disassembly and maintenance. These fittings are commonly used in automotive and industrial applications where fluid transfer is necessary, such as in fuel, hydraulic, and cooling systems 1.

Purpose of the 3095293 Male Union Fitting in Truck Operations

In the context of commercial trucks, the 3095293 Male Union Fitting serves to connect various components within the truck’s fluid systems. Its design allows for the transfer of fluids under pressure, ensuring that systems like the fuel delivery, hydraulic, and cooling systems operate efficiently. The fitting’s role is to provide a secure connection point that can withstand the pressures and temperatures encountered in these systems 2.

Key Features of the 3095293 Male Union Fitting

The 3095293 Male Union Fitting is characterized by several features that enhance its performance and durability. It is constructed from high-quality materials that resist corrosion and wear, ensuring longevity in demanding environments. The fitting’s design includes precise threading and a robust union nut, which contribute to a secure and leak-proof connection. Additionally, it may feature unique attributes such as a protective coating or specialized threading to further improve its functionality.

Benefits of Using the 3095293 Male Union Fitting

Utilizing the 3095293 Male Union Fitting in commercial truck operations offers several advantages. It contributes to improved system efficiency by ensuring secure and leak-free connections. The fitting’s design also enhances the reliability of the fluid systems it serves, reducing the likelihood of unexpected failures. Furthermore, its ease of installation and maintenance simplifies repair and replacement processes, minimizing downtime for commercial trucks.

Installation and Usage Guidelines

To install the 3095293 Male Union Fitting, follow these steps: First, ensure the mating female fitting is clean and free of debris. Apply a compatible thread sealant to the male threads of the fitting. Carefully screw the male fitting into the female fitting, using the union nut to secure the connection. Tighten the nut until snug, being careful not to over-tighten, which could damage the fitting or the connected components. Always refer to the manufacturer’s guidelines for specific torque specifications and best practices 3.

Troubleshooting Common Issues

Common issues with Male Union Fittings may include leaks, difficulty in disassembly, or corrosion. To address leaks, first, ensure the fitting is properly tightened. If leaks persist, inspect the fitting and mating components for damage or wear. Difficulty in disassembly may be resolved by applying penetrating oil to the threads and allowing it to sit for a period before attempting to unscrew the fitting. Corrosion can be mitigated by using fittings made from corrosion-resistant materials and applying protective coatings where applicable.

Maintenance Tips

Regular maintenance of the 3095293 Male Union Fitting involves inspection for signs of wear, corrosion, or leaks. Cleaning the fitting and its connections can prevent buildup that may lead to issues. It is also important to periodically check the tightness of the union nut to ensure the connection remains secure. If significant wear or damage is observed, consider replacing the fitting to maintain system integrity and performance.

Cummins: A Brief Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. With a history spanning over a century, Cummins has established a reputation for quality, reliability, and innovation in the commercial vehicle industry. The company’s extensive product range includes engines, powertrains, and components designed to meet the demanding requirements of commercial and industrial applications, underscoring the quality and reliability of the 3095293 Male Union Fitting.

Compatibility with Engine Models

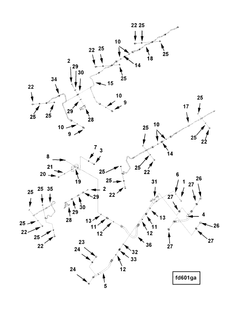

This Cummins part is designed to integrate seamlessly with a variety of Cummins engine models. It is compatible with the following engines:

- Cummins 6B5.9 and 6C8.3 Engines: Part of the Cummins B and C series, known for their robust performance and reliability.

- Cummins K19, K38, and K50 Engines: Part of the Cummins K series, widely used in various industrial and commercial applications.

- Cummins QSK38 and QSK50 Engines: Part of the Cummins QSK series, known for their high power output and efficiency.

- Cummins QSK60 Engines: Part of the Cummins QSK series, offering high performance and efficiency.

- Cummins KTA19GC Engines: Part of the Cummins KTA series, known for its reliability and performance in various applications.

Role in Engine Systems

The Male Union Fitting 3095293 is instrumental in ensuring the seamless connection and operation of various engine components. Its applications span across multiple systems, enhancing the efficiency and reliability of the engine.

Fuel System Integration

In the fuel system, the Male Union Fitting is employed to connect the fuel supply hose to the fuel strainer. This connection is vital for maintaining a consistent fuel flow to the engine, ensuring optimal performance. Additionally, it plays a role in linking the fuel drain plumbing, facilitating the removal of contaminants and water from the fuel system.

Turbocharger Systems

Within turbocharger systems, the fitting is used to join the turbocharger oil supply hose to the turbocharger supply hose. This connection is essential for lubricating the turbocharger, reducing friction, and enhancing its longevity. The fitting also aids in connecting the turbocharger oil supply to the long block assembly, ensuring that the turbocharger receives the necessary oil supply for efficient operation.

Engine Monitoring and Support

The Male Union Fitting is also integral in the engine monitoring system, where it connects various sensors and gauges to the engine block. This allows for real-time monitoring of engine parameters, ensuring that the engine operates within safe limits. Furthermore, it is used in the front engine support system, connecting the front engine support to the engine mounting, providing stability and reducing vibrations.

Plumbing and Hose Connections

In plumbing applications, the fitting is utilized to connect the oil supply hose to the crankcase breather, facilitating the removal of gases and moisture from the crankcase. It also plays a role in connecting the flexible hose to the gear cover, ensuring a secure and leak-free connection.

Accessory and Base Part Connections

The fitting is employed in connecting various accessories to the base part and base parts of the engine. This includes connecting the drive fan to the engine, enhancing cooling efficiency. It also aids in connecting the cylinder to the cylinder block, ensuring a secure fit and optimal engine performance.

Conclusion

The Male Union Fitting 3095293 is a versatile component that plays a significant role in the operation and efficiency of various engine systems. Its applications range from fuel system integration to turbocharger lubrication, engine monitoring, and accessory connections, making it an essential part in engine maintenance and operation.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.