This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

The Cummins 3095291 Male Connector is a specialized component designed for use in commercial truck operations. This connector facilitates the connection between various systems within the truck, ensuring efficient and reliable operation. Its significance lies in its ability to maintain the integrity of connections in demanding environments, contributing to the overall performance and durability of the vehicle 1.

Basic Concepts of Male Connectors

Male connectors are components used to join two parts of a system together, typically by fitting into a corresponding female connector. They are integral in both automotive and industrial applications, where they enable the transfer of fluids, electrical signals, or other types of data. Male connectors are designed to provide a secure and stable connection, minimizing the risk of leaks or disruptions in service 2.

Purpose of the Cummins 3095291 Male Connector

The Cummins 3095291 Male Connector serves a specific function within the truck’s systems, whether electrical or fluid-based. It ensures a reliable connection between components, allowing for the smooth operation of the truck. This connector is engineered to withstand the rigors of commercial use, providing a durable link that supports the truck’s performance under various conditions 3.

Key Features

The Cummins 3095291 Male Connector is characterized by several key features that enhance its performance and durability. These include a robust material composition designed to resist wear and corrosion, a precise design that ensures a secure fit, and unique characteristics that may include specialized coatings or threading to improve connection stability and longevity 4.

Benefits

Utilizing the Cummins 3095291 Male Connector offers several advantages. It contributes to improved system efficiency by ensuring a reliable connection, which can lead to enhanced truck performance. Additionally, its durable construction supports long-term reliability, potentially reducing the need for frequent replacements. These factors can also contribute to cost savings over time.

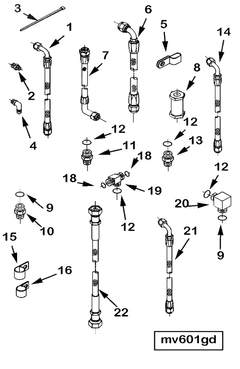

Installation Process

Installing the Cummins 3095291 Male Connector requires careful attention to ensure a proper fit and function. The process involves preparing the connection point, aligning the connector with the corresponding female part, and securing it in place. Tools or additional components may be necessary to complete the installation, depending on the specific application.

Troubleshooting Common Issues

Common issues with the Cummins 3095291 Male Connector may include connection failures or leaks. Troubleshooting these problems involves inspecting the connector for signs of damage or wear, ensuring it is properly aligned and secured, and addressing any environmental factors that may affect its performance. Regular checks can help identify and resolve issues before they lead to more significant problems.

Maintenance Tips

To ensure the longevity and optimal performance of the Cummins 3095291 Male Connector, regular maintenance is recommended. This includes cleaning the connector to remove any debris or contaminants, inspecting it for signs of wear or damage, and replacing it if necessary. Adhering to these maintenance practices can help maintain the connector’s efficiency and reliability.

Compatibility

The Cummins 3095291 Male Connector is designed to fit seamlessly with various engine models, ensuring compatibility and reliability across different applications. This connector is engineered to meet the stringent standards required for high-performance and durability in demanding environments.

Engine Compatibility

- 6B5.9 and K38 Engines

The 3095291 Male Connector is specifically engineered to fit the 6B5.9 and K38 engines. These engines are known for their robust performance and are often used in heavy-duty applications. The connector’s design ensures a secure and leak-proof connection, which is crucial for maintaining engine efficiency and preventing potential failures.

- K50 Engine

Similarly, the K50 engine also benefits from the 3095291 Male Connector. This connector is tailored to fit the specific requirements of the K50, ensuring that it can handle the pressures and demands of this engine model. The precision engineering of the connector guarantees a perfect fit, enhancing the overall performance and longevity of the engine.

Grouping for Ease of Use

For ease of use and better understanding, the 3095291 Male Connector is compatible with the following engine groups:

- 6B5.9 and K38 Engines: These engines share similar design characteristics and operational requirements, making the 3095291 connector suitable for both.

- K50 Engine: This engine, while distinct, also benefits from the same connector due to its design and engineering standards.

By ensuring compatibility across these engines, the 3095291 Male Connector provides a reliable solution for maintaining and repairing these critical components.

Role of 3095291 Male Connector in Engine Systems

The 3095291 Male Connector is integral to the efficient operation of various engine components. It facilitates the secure connection between different parts, ensuring optimal performance and reliability.

Integration with Oil Systems

-

Oil Manifold and Oil Connections: The Male Connector is used to link the oil manifold with both the left and right bank oil supply and control connections. This ensures a consistent oil flow to critical components such as the camshaft and camshaft gear, which rely on precise lubrication for smooth operation.

-

Oil Transfer and Control Valves: It plays a role in connecting the oil transfer connection to the oil control valve, allowing for regulated oil distribution to areas like the cylinder head and rocker housing. This regulated flow is essential for maintaining the integrity and performance of these components.

Role in Aftercooler Systems

- Aftercooler Core and Plumbing: The Male Connector is employed in the aftercooler plumbing to ensure a tight seal between the aftercooler core and its associated pipes. This connection is vital for maintaining the efficiency of the aftercooler system, which is responsible for reducing the temperature of the air before it enters the engine.

Application in Fuel Injection Systems

- Injectors and Protective Covers: In fuel injection systems, the Male Connector is used to secure injectors to their respective protective covers. This ensures that the injectors are properly aligned and sealed, which is important for the accurate delivery of fuel to the combustion chambers.

Use in Dual STC Systems

- Dual STC K38 and K50 Kits: The connector is also found in the Dual STC K38 and K50 kits, where it helps in establishing reliable connections between various components within these systems. This is particularly important for the hydro-mechanical step, where precise fluid dynamics are required for optimal performance.

Check Valve Integration

- Check Valve Connections: The Male Connector is utilized in check valve systems to prevent backflow, ensuring that fluids move in the intended direction within the engine. This is important for maintaining the efficiency and reliability of the engine’s fluid systems.

Conclusion

In summary, the Cummins 3095291 Male Connector is a versatile component that enhances the functionality and reliability of various engine systems by ensuring secure and efficient connections between critical parts. Its robust design, compatibility with multiple engine models, and role in maintaining system integrity make it an essential component for commercial truck operations.

-

Eret, Angelina. Dynamic and Fatigue Assessment of Heavy-Duty Engine Valves. Springer Nature, 2024.

↩ -

Bennett, Sean. Modern Diesel Technology Light Duty Diesels. Cengage Learning, 2012.

↩ -

Hilgers, Michael. Vocational Vehicles and Applications. Springer Nature, 2023.

↩ -

Bari, Saiful. Diesel Engine Combustion, Emissions and Condition Monitoring. InTech, 2013.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.