This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

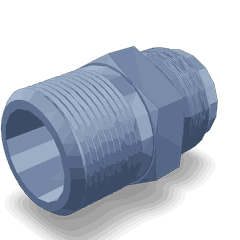

The Cummins 3034122 Male Connector is a specialized component designed for use in commercial trucks. Its purpose is to facilitate secure and efficient connections within the truck’s systems, ensuring reliable operation and performance. This connector is significant in maintaining the integrity of the truck’s various systems, contributing to overall vehicle efficiency and safety 1.

Basic Concepts of Male Connectors

A male connector is a type of fitting used to join two components together, typically by inserting into a corresponding female connector. In automotive and industrial settings, male connectors play a vital role in establishing secure connections for fluid transfer, electrical signals, and other applications. They are designed to provide a tight seal, preventing leaks and ensuring consistent performance 2.

Purpose of the Cummins 3034122 Male Connector

The Cummins 3034122 Male Connector is specifically designed to connect various components within a truck’s system. It ensures a reliable and secure connection, which is crucial for the proper functioning of the truck’s systems. This connector is used in applications where durability and a tight seal are required, such as in fuel lines, hydraulic systems, and other critical areas.

Key Features

The Cummins 3034122 Male Connector features a robust design that includes high-quality materials to ensure durability and reliability. It is constructed from materials that resist corrosion and wear, enhancing its performance in demanding environments. The connector also includes design elements that facilitate easy installation and a secure fit, ensuring that connections remain intact under various operating conditions.

Benefits

The Cummins 3034122 Male Connector offers several benefits, including improved reliability due to its secure connection and durable construction. It is designed for ease of installation, reducing downtime during maintenance procedures. Additionally, its compatibility with various systems ensures that it can be used in a wide range of applications, providing versatility for different truck models and systems.

Installation Process

Installing the Cummins 3034122 Male Connector involves several steps to ensure a proper and secure connection. Begin by identifying the correct location for the connector within the truck’s system. Use the appropriate tools to prepare the connection point, ensuring it is clean and free of debris. Insert the male connector into the corresponding female connector, ensuring a tight fit. Verify the connection by checking for any leaks or loose fittings. Follow safety precautions, such as wearing protective gloves and eyewear, to prevent injury during installation.

Maintenance Tips

To ensure the longevity and optimal performance of the Cummins 3034122 Male Connector, regular maintenance is recommended. Inspect the connector periodically for signs of wear, corrosion, or damage. Clean the connector and surrounding areas to remove any buildup that could affect performance. If any issues are detected, address them promptly to prevent further damage or system failure.

Troubleshooting Common Issues

Common issues with the Cummins 3034122 Male Connector may include leaks, loose connections, or corrosion. To troubleshoot these problems, first, inspect the connector and surrounding areas for any visible damage or wear. Ensure that the connection is secure and tight. If corrosion is present, clean the affected areas and consider applying a corrosion-resistant coating. For persistent issues, consult the manufacturer’s guidelines or seek professional assistance.

Safety Considerations

When working with the Cummins 3034122 Male Connector, it is important to follow safety practices to prevent injury and ensure proper installation. Wear appropriate personal protective equipment, such as gloves and eyewear, to protect against sharp edges and potential leaks. Ensure that the truck is turned off and the system is depressurized before beginning any work. Follow all manufacturer guidelines and safety instructions to maintain a safe working environment.

Cummins Corporation

Cummins Corporation is a leading manufacturer of diesel and natural gas engines, as well as related technologies. With a history of innovation and quality, Cummins has established a strong reputation in the commercial truck industry. The company offers a wide range of products designed to meet the demands of various applications, ensuring reliable performance and efficiency for its customers.

Compatibility with Cummins Engines

The Male Connector 3034122, manufactured by Cummins, is designed to ensure seamless integration and functionality across various engine models. This part is engineered to fit precisely within the engine systems, facilitating essential connections and fluid transfers.

K38 Engine Series

In the K38 engine series, the Male Connector 3034122 is meticulously designed to align with the specific requirements of this engine model. Its robust construction and precise fitment ensure that it can handle the operational demands of the K38 engine, providing reliable performance and durability.

K50 Engine Series

Similarly, for the K50 engine series, the Male Connector 3034122 is tailored to meet the unique specifications of this engine. Its compatibility with the K50 engine ensures that it can effectively manage the fluid dynamics and connections necessary for the engine’s optimal operation.

Grouped Compatibility

When considering the K38 and K50 engines together, the Male Connector 3034122 demonstrates a versatile design that accommodates the distinct needs of both engine series. This adaptability highlights Cummins’ commitment to providing high-quality, reliable components that enhance engine performance and longevity.

Role of Part 3034122 Male Connector in Engine Systems

The 3034122 Male Connector is a vital component in the efficient operation of various engine systems. It facilitates the secure and reliable connection between different parts, ensuring optimal performance and safety.

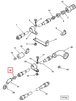

Integration with Aeroquip Components

When paired with an Aeroquip Lube Hose or Aeroquip Lubricating Oil Hose, the 3034122 Male Connector ensures a tight seal, preventing leaks and maintaining the integrity of the lubrication system. This connection is vital for delivering lubricants to moving parts, reducing friction, and enhancing engine longevity.

Connection to Hose Mount and Filter Systems

The Male Connector also plays a significant role when integrated with a Hose Mount and a Lubricating Oil Mounting Filter. It provides a stable and leak-proof junction, allowing for the smooth flow of lubricants through the filter. This setup ensures that the oil remains clean and free from contaminants, which is essential for the engine’s health.

Application in Pump Systems

In pump systems, the 3034122 Male Connector is used to link the pump to the lubrication lines. This connection is fundamental for the consistent delivery of lubricants to various engine components, ensuring they operate smoothly and efficiently.

Use with Raw Water Systems

For engines that incorporate a Raw Water cooling system, the Male Connector is employed to join the raw water lines securely. This connection is important for maintaining the cooling efficiency of the engine, preventing overheating, and ensuring reliable operation.

Compatibility with Stratoflex Hoses

The connector is also compatible with Stratoflex Lube Hose and Stratoflex Lube Oil Hose. Its use in these systems ensures a robust and durable connection, capable of withstanding the pressures and temperatures associated with engine lubrication.

Conclusion

The Cummins 3034122 Male Connector is a versatile and essential component that enhances the functionality and reliability of various engine systems by providing secure and efficient connections. Its robust design, compatibility with multiple systems, and ease of installation make it a valuable part for maintaining the performance and safety of commercial trucks.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.