This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

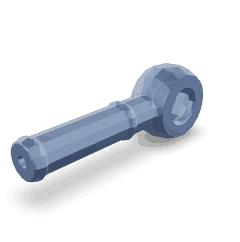

The 5301855 Banjo Connector, a component manufactured by Cummins, is integral to the operations of heavy-duty trucks. This part contributes to the efficiency and reliability of hydraulic and fuel systems in commercial vehicles.

Purpose and Function

This Cummins part facilitates the transfer of fluids within the hydraulic and fuel systems of heavy-duty trucks. It ensures the integrity of these systems by providing a secure connection point for hoses and pipes, enabling the smooth and consistent flow of fluids necessary for the operation of various truck components 1.

Key Features

The design of the 5301855 includes several elements that enhance its performance and durability. It is constructed from materials that resist corrosion and wear, ensuring longevity in demanding environments. The connector features specific connection types that allow for easy integration with various hose and pipe configurations. Additionally, unique attributes such as reinforced seals and precision-machined surfaces contribute to its reliable operation 2.

Benefits

The 5301855 offers several advantages. It improves the efficiency of fluid transfer within the system, enhances the overall reliability of the hydraulic and fuel systems, and is designed for ease of installation and maintenance. These features contribute to reduced downtime and increased operational efficiency for commercial trucks 3.

Installation Process

Proper installation of the 5301855 involves several steps to ensure optimal performance. The process begins with gathering the necessary tools and preparing the connection points. Following manufacturer guidelines, the connector is then securely attached, ensuring all connections are tight and free from leaks. Attention to detail during installation is crucial for the connector’s effectiveness.

Maintenance Tips

To prolong the lifespan of the 5301855, regular maintenance is recommended. This includes routine inspections for signs of wear or damage, cleaning the connector and surrounding areas to prevent buildup, and following manufacturer guidelines for when to consider replacement. Adhering to these practices helps maintain the connector’s performance and reliability.

Troubleshooting Common Issues

Frequent problems associated with the 5301855 may include leaks or connection failures. Diagnostic steps to identify these issues involve checking for visible signs of damage, ensuring all connections are secure, and verifying the integrity of the seals. Repair solutions may range from tightening connections to replacing damaged components, depending on the issue identified.

Safety Considerations

When working with the 5301855, observing safety protocols is important. This includes handling fluids with care to avoid spills and ensuring all connections are made according to manufacturer guidelines to prevent accidents. Adhering to these safety considerations protects both the equipment and the individuals performing maintenance or repairs.

Cummins Overview

Cummins Inc. is a leader in the commercial truck industry, known for its wide range of products and commitment to quality and reliability. With a history of innovation and excellence, Cummins provides components like the 5301855 that are designed to meet the demanding requirements of heavy-duty truck operations. The company’s reputation is built on its ability to deliver durable, high-performance parts that contribute to the efficiency and reliability of commercial vehicles.

Role of Part 5301855 Banjo Connector in Engine Systems

The 5301855 is an essential component in the fluid dynamics of engine systems, facilitating the secure and efficient transfer of fluids between various parts. Its application spans across several key components, ensuring optimal performance and reliability.

Exhaust Cooler Water Outlet Tube

In the context of the Exhaust Cooler Water Outlet Tube, the Banjo Connector plays a significant role in maintaining a sealed connection. This ensures that the coolant flow from the exhaust cooler is uninterrupted, which is vital for dissipating heat effectively and maintaining the integrity of the exhaust system.

Hardware Kit

When integrated with a Hardware Kit, the Banjo Connector provides a robust connection point for various plumbing components. Its design allows for easy installation and removal, which is particularly beneficial during maintenance or upgrades of the engine system.

Plumbing

In the broader scope of engine Plumbing, the Banjo Connector is used to join different sections of the coolant and fuel lines. Its ability to create a leak-proof seal is paramount in preventing fluid loss and ensuring consistent pressure throughout the system.

Exhaust Recirculation Water

For systems involving Exhaust Recirculation Water, the Banjo Connector is instrumental in routing the recirculated water back into the system. This not only enhances the efficiency of the exhaust treatment process but also contributes to reducing emissions.

Vent

In applications where a Vent is required, the Banjo Connector aids in the secure attachment of vent lines to the engine system. This is important for pressure regulation and the safe release of gases, contributing to the overall stability of the engine operation.

Engine Coolant

Finally, in the circulation of Engine Coolant, the Banjo Connector ensures that the coolant path is maintained without leaks. This is essential for the thermal management of the engine, directly influencing its performance and longevity.

Conclusion

The 5301855 Banjo Connector by Cummins is a vital component in the hydraulic and fuel systems of heavy-duty trucks. Its design and features contribute to the efficiency, reliability, and safety of these systems. Proper installation, maintenance, and adherence to safety protocols are crucial for maximizing the performance and lifespan of this part.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.