This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

The Cummins 5270516 Banjo Connector is a component designed for use in commercial trucks. It serves a specific function within the vehicle’s fluid systems, contributing to the overall operation and efficiency of the truck. Understanding its purpose and significance can provide insight into the complexities of truck maintenance and operation.

Basic Concepts of Banjo Connectors

A banjo connector is a type of fitting used in fluid systems to join hoses or pipes. It typically consists of a bolt, a banjo fitting, and washers. The connector operates by creating a sealed connection that allows fluid to pass through while preventing leaks. In the context of a truck’s hydraulic or fuel system, the banjo connector ensures that fluid is delivered efficiently and under the correct pressure to various components 1.

Purpose of the 5270516 Banjo Connector

This Cummins part plays a role in the operation of a truck by facilitating the connection of hoses or pipes in hydraulic or fuel systems. It is designed to provide a secure and leak-free connection, ensuring that fluid is delivered consistently and efficiently to the necessary components. This connector is integral to maintaining the performance and reliability of the truck’s fluid systems.

Key Features

The 5270516 is characterized by its robust design and the materials used in its construction. It is typically made from high-quality steel or other durable materials, which contribute to its strength and resistance to wear. The connector may also feature unique attributes such as corrosion-resistant coatings or specialized washers that enhance its performance and longevity.

Benefits

This part offers several benefits, including improved system efficiency, increased reliability, and ease of maintenance. By providing a secure connection, it helps to ensure that fluid systems operate smoothly and without interruption. Additionally, its design allows for straightforward installation and maintenance, reducing downtime and facilitating quick repairs when necessary.

Installation Process

Installing the 5270516 involves several steps to ensure a secure and leak-free connection. The process typically requires specific tools, such as a torque wrench, to achieve the correct tightening specifications. Best practices include inspecting the connector and mating surfaces for cleanliness and damage before installation, applying the appropriate amount of thread sealant, and tightening the connector to the manufacturer’s specified torque 2.

Troubleshooting Common Issues

Common problems associated with banjo connectors, such as leaks or connection failures, can often be traced to improper installation, wear and tear, or damage to the connector or mating surfaces. Troubleshooting steps may include inspecting the connector for signs of wear, ensuring that it is properly tightened, and replacing any damaged components. Regular maintenance and inspection can help to prevent these issues 3.

Maintenance Tips

To ensure the long-term performance and reliability of the 5270516, regular maintenance is recommended. This includes periodic inspection for signs of wear or damage, cleaning the connector and mating surfaces to remove any debris or contaminants, and replacing washers or other components as needed. Adhering to manufacturer-recommended inspection intervals can help to identify potential issues before they lead to system failures.

Cummins: A Brief Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. With a history spanning over a century, Cummins has established a reputation for quality and reliability in the commercial truck industry. The company’s extensive product range includes components and systems designed to enhance the performance, efficiency, and durability of commercial vehicles. The 5270516 is one example of Cummins’ commitment to providing high-quality, reliable parts for the trucking industry.

Cummins Engine Compatibility with Part 5270516

The Banjo Connector part 5270516, manufactured by Cummins, is a component in the fuel and fluid systems of various engines. This part is designed to provide a secure and leak-proof connection for hoses, ensuring the integrity of the system. Below is a detailed description of how this part fits with the specified engines.

L9 CM2350 L120C and QSL9 CM2250

The L9 CM2350 L120C and QSL9 CM2250 engines both utilize the Banjo Connector part 5270516 in their fuel and fluid systems. This part is typically used in applications where a robust connection is required to withstand the operational stresses of the engine. The connector’s design ensures that the hoses remain securely attached, preventing any leaks that could compromise the engine’s performance.

QSL9 CM2350 L102

The QSL9 CM2350 L102 engine also incorporates the Banjo Connector part 5270516 in its design. This engine, like the others, benefits from the secure and reliable connection provided by the part. The connector’s role is vital in maintaining the efficiency and safety of the engine’s fuel and fluid systems.

In summary, the Banjo Connector part 5270516 is a component for the L9 CM2350 L120C, QSL9 CM2250, and QSL9 CM2350 L102 engines, ensuring that the hoses remain securely attached and the systems operate without leaks.

Role of Part 5270516 Banjo Connector in Engine Systems

In engine systems, the part 5270516 is instrumental in ensuring the secure and efficient transfer of fluids. This component is typically integrated into the plumbing system, where it connects various parts to facilitate the smooth flow of substances such as fuel.

When installed, the Banjo Connector links the fuel filter to the fuel lines. This connection is vital for maintaining the integrity of the fuel delivery system. The Banjo Connector’s design allows for a leak-proof seal, which is essential for preventing fuel leaks that could lead to dangerous situations.

Additionally, the Banjo Connector plays a role in the overall maintenance of the engine system. Its placement between the fuel filter and the fuel lines means that it can be easily accessed for inspection or replacement, should the need arise. This accessibility is beneficial for routine maintenance checks, ensuring that the engine system operates efficiently and safely.

In summary, the Banjo Connector is a key component in the engine’s fluid dynamics, providing a reliable connection that supports the consistent performance of the fuel system.

Conclusion

The Cummins 5270516 Banjo Connector is a critical component in the fluid systems of commercial trucks, ensuring secure and efficient fluid transfer. Its robust design, ease of maintenance, and compatibility with various Cummins engines highlight its importance in maintaining the performance and reliability of truck fluid systems. Regular maintenance and proper installation are essential to maximize the benefits of this part.

SPECIFICATIONS

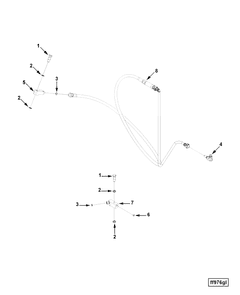

BILL OF MATERIALS

| Name | Quantity | Part Number |

|---|---|---|

| Pipe Plug | 1 | 3863362 |

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.