This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

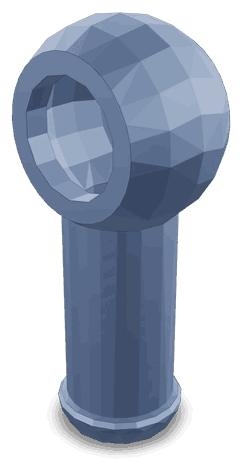

The Cummins 5266563 Banjo Connector is a specialized component designed for use in commercial trucks. It serves a specific function within the vehicle’s fluid systems, contributing to the overall efficiency and reliability of the truck’s operation. Understanding its purpose and role is fundamental for maintaining and optimizing the performance of commercial vehicles.

Basic Concepts of Banjo Connectors

A banjo connector is a type of fitting used in fluid systems to join two pipes or hoses. It typically consists of a short, curved pipe with fittings on each end, resembling the shape of a banjo musical instrument. Within automotive and industrial settings, banjo connectors are commonly employed in hydraulic, fuel, and brake systems. They facilitate the transfer of fluids under pressure, ensuring a secure and leak-free connection between components 1.

Purpose of the 5266563 Banjo Connector

The 5266563 Banjo Connector plays a role in the operation of a truck by connecting various components within the hydraulic or fuel system. Its design allows for the efficient transfer of fluids, contributing to the system’s overall performance. By providing a reliable connection point, it helps maintain the integrity of the fluid pathway, ensuring consistent pressure and flow 2.

Key Features

The 5266563 Banjo Connector is constructed from high-quality materials, ensuring durability and resistance to corrosion. Its design includes specific connection types that are compatible with various system components, enhancing its versatility. Additionally, features such as reinforced fittings and precise engineering contribute to its performance and longevity 3.

Benefits

The advantages of using the 5266563 Banjo Connector include improved system efficiency due to its precise design, which minimizes fluid leakage and ensures consistent pressure. Its reliability is enhanced by the use of high-quality materials and construction techniques. Furthermore, the connector is designed for ease of installation, reducing downtime during maintenance procedures.

Installation Process

Proper installation of the 5266563 Banjo Connector involves several steps to ensure a secure and leak-free connection. Begin by identifying the correct location for the connector within the system. Use the appropriate tools to connect the banjo fitting to the system components, ensuring all connections are tight and secure. It is important to follow manufacturer guidelines for torque specifications to avoid over-tightening, which could damage the fittings.

Common Issues and Troubleshooting

Common problems associated with banjo connectors include leaks and corrosion. To address these issues, regularly inspect the connections for signs of wear or damage. If a leak is detected, disassemble the connection, inspect the fittings for damage, and replace any compromised components. Corrosion can be mitigated by using connectors made from corrosion-resistant materials and ensuring the system is properly maintained.

Maintenance Tips

To ensure the long-term performance of the 5266563 Banjo Connector, regular maintenance is recommended. This includes periodic inspection of the connections for signs of wear, leakage, or corrosion. Cleaning the fittings and surrounding areas can prevent the buildup of contaminants that may affect the connector’s performance. Additionally, following the manufacturer’s guidelines for maintenance intervals and procedures will help maintain the system’s efficiency.

Safety Considerations

When working with the 5266563 Banjo Connector, it is important to observe safety guidelines to protect against injury and ensure the system operates correctly. This includes handling fluids with care to avoid spills and contamination. Ensure that the system pressure is within the specified limits to prevent damage to the connector or other components. Always use personal protective equipment when performing maintenance or repairs.

Cummins Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. With a history spanning over a century, Cummins has established a reputation for quality and innovation in the commercial truck industry. Its product range includes a variety of engines and components designed to meet the demanding requirements of commercial vehicles, ensuring reliability and performance.

Cummins Banjo Connector 5266563 Compatibility

The Cummins Banjo Connector part number 5266563 is a versatile component designed to fit a variety of Cummins engines. This part is essential for maintaining the integrity of hydraulic and fuel lines, ensuring that connections remain secure and leak-free. Below is a detailed description of the engines with which this banjo connector is compatible.

Compatible Engines

- 6C8.3

- B6.7 CM2350 B135B

- B6.7 CM2670 B153B

- B6.7 CM2670 B164C

- D4.0 CM2620 D103B

- F4.5 CM2620 F139B

- ISB/ISD4.5 CM2150 B119

- ISB/ISD6.7 CM2150 SN

- ISB5.9 CM2880 B127

- ISBE CM2150

- ISBE4 CM850

- ISL9 CM2150 SN

- ISL9.5 CM2880 L138

- L8.9 CM2670 L134C

- L9 CM2670 L128B

The Cummins Banjo Connector part number 5266563 is a critical component for a wide range of Cummins engines, ensuring that hydraulic and fuel lines remain securely connected. Its compatibility with various engine series underscores its importance in maintaining the performance and reliability of these engines.

Role of Part 5266563 Banjo Connector in Engine Systems

The 5266563 Banjo Connector is an essential component in various engine systems, facilitating efficient and reliable connections between different parts. Its application spans across several key areas, enhancing the overall performance and functionality of the engine.

Connection

In engine systems, the 5266563 Banjo Connector is primarily used to create secure and leak-proof connections between hoses and fittings. This is particularly important in high-pressure systems where any leakage can lead to significant performance issues. The Banjo Connector ensures that the connection remains intact under varying pressure conditions, maintaining the integrity of the fluid pathways.

Water Inlet

When it comes to the water inlet system, the 5266563 Banjo Connector plays a vital role in directing coolant into the engine block. This connection is critical for maintaining optimal engine temperature, as it allows coolant to flow smoothly from the radiator to the engine. The Banjo Connector’s design ensures a tight seal, preventing coolant loss and ensuring consistent cooling performance.

Plumbing

In the broader context of engine plumbing, the 5266563 Banjo Connector is used to join various pipes and hoses that carry fluids such as oil, coolant, and fuel. Its robust construction and precise fitting capabilities make it ideal for withstanding the rigors of engine operation. The connector helps in creating a cohesive plumbing network that enhances the efficiency of fluid distribution throughout the engine system.

Cabin Heater

The 5266563 Banjo Connector also finds its application in the cabin heating system. It connects the hoses that transport hot coolant from the engine to the heater core inside the vehicle’s cabin. This connection is essential for providing warm air to the passengers, especially in cold weather conditions. The Banjo Connector ensures that the coolant flow is uninterrupted, thereby maintaining a comfortable cabin temperature.

Conclusion

Overall, the 5266563 Banjo Connector is a versatile component that contributes to the reliable operation of various engine systems by ensuring secure and efficient fluid connections. Its role in maintaining the integrity of hydraulic and fuel lines, as well as its compatibility with a wide range of Cummins engines, underscores its importance in the commercial truck industry.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.