This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

The 5263691 Banjo Connector, manufactured by Cummins, is a component designed for use in commercial truck operations. Cummins, a well-established name in the industry, produces a range of parts and systems that contribute to the efficiency and reliability of heavy-duty trucks. This part is significant in maintaining the integrity of fluid systems within these vehicles.

Basic Concepts of Banjo Connectors

A banjo connector is a type of fitting used in fluid systems to join hoses or pipes. It typically consists of a short, cylindrical body with bolt holes at each end, allowing it to be secured between two components. In a truck’s hydraulic or fuel system, the banjo connector facilitates the transfer of fluids under pressure, ensuring a secure and leak-free connection 3.

Purpose of the 5263691 Banjo Connector

The 5263691 Banjo Connector is specifically designed to connect hoses or pipes in a truck’s hydraulic or fuel system. Its role is to provide a reliable connection point that can withstand the pressures and conditions present in these systems. By ensuring a secure fit, it helps maintain the efficiency and safety of fluid transfer within the truck 1.

Key Features

This Cummins part features several design elements that enhance its performance and durability. It is constructed from high-quality materials, typically steel or stainless steel, which offer resistance to corrosion and wear. The connector’s design includes precision-machined surfaces to ensure a tight seal, and it may incorporate gaskets or O-rings to further prevent leaks. Additionally, the connector is engineered to withstand high pressures, making it suitable for demanding applications 2.

Benefits

The 5263691 Banjo Connector offers several benefits that contribute to its effectiveness in commercial truck operations. Its robust construction and precise engineering result in improved fluid transfer efficiency. The connector’s durability ensures long-term reliability, reducing the need for frequent replacements. Furthermore, its design helps prevent leaks, which can be critical in maintaining the performance and safety of the truck’s fluid systems 3.

Installation Process

Proper installation of the 5263691 Banjo Connector is vital to ensure a secure and leak-free connection. The process involves several steps: First, the connecting surfaces should be cleaned to remove any debris or contaminants. Next, the connector should be positioned between the hose or pipe ends, ensuring it is aligned correctly. Using the appropriate tools, the bolts should be tightened to the specified torque to secure the connection without over-tightening, which could damage the connector or the connected components 1.

Troubleshooting Common Issues

Common problems associated with banjo connectors include leaks and corrosion. To address these issues, it is important to regularly inspect the connector and its fittings for signs of wear or damage. If a leak is detected, the connector should be disassembled, cleaned, and reassembled, ensuring that all components are in good condition and properly aligned. In cases of corrosion, the affected parts may need to be replaced to maintain the integrity of the fluid system 2.

Maintenance Tips

To prolong the lifespan of the 5263691 Banjo Connector, regular maintenance practices should be followed. This includes periodic inspection of the connector and its fittings for signs of wear, corrosion, or leaks. Cleaning the connector and its surrounding areas can help prevent the buildup of contaminants that could lead to performance issues. Additionally, ensuring that the connector is properly torqued during installation and re-tightened as needed can help maintain a secure connection 3.

Safety Considerations

When working with the 5263691 Banjo Connector, particularly in relation to fluid systems under pressure, several safety precautions should be observed. Always ensure that the system is depressurized before attempting any maintenance or repairs. Use the appropriate personal protective equipment, such as gloves and safety glasses, to protect against potential hazards. Follow all manufacturer guidelines and torque specifications to avoid over-tightening, which could lead to damage or failure of the connector 1.

Cummins: Manufacturer Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes a wide range of power solutions, including engines, filtration systems, and aftermarket parts. Founded in 1919, Cummins has built a reputation for innovation, quality, and reliability in the commercial truck industry. The company’s extensive product range and commitment to customer satisfaction have made it a trusted name among fleet operators and maintenance professionals 2.

Cummins Banjo Connector 5263691 in Engine Applications

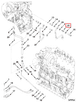

The Cummins Banjo Connector 5263691 is a critical component in various engine systems, ensuring secure and leak-free connections for hydraulic or fuel lines. This part is designed to fit seamlessly into the engine architecture, providing a reliable seal that is essential for maintaining system integrity.

QSB6.7 CM2250 Engines

In the QSB6.7 CM2250 engines, the Banjo Connector 5263691 is utilized in several critical applications. It is often employed in the fuel delivery system, where it connects the fuel lines to the fuel pump or injectors. This connection is vital for ensuring that fuel is delivered consistently and without leaks, which is crucial for engine performance and efficiency.

The connector’s design allows for easy installation and removal, making it convenient for maintenance and repairs. Its robust construction ensures that it can withstand the high pressures and temperatures typical in engine environments, contributing to the overall reliability of the engine.

The use of the Banjo Connector 5263691 in these engines highlights Cummins’ commitment to providing high-quality, durable components that enhance engine performance and longevity 2.

Role of Part 5263691 Banjo Connector in Engine Systems

The Part 5263691 Banjo Connector is an essential component in the integration and functionality of various engine systems, particularly in the context of plumbing and turbocharger setups.

Turbocharger Plumbing

In turbocharger systems, the Banjo Connector is utilized to join hoses and pipes that carry fluids such as oil or coolant. This connection ensures a secure and leak-proof seal, which is vital for maintaining the pressure and flow necessary for the turbocharger to operate efficiently. The Banjo Connector’s design allows for easy installation and removal, facilitating maintenance and repairs without the need for specialized tools 3.

General Plumbing Applications

Beyond turbochargers, the Banjo Connector is widely used in general engine plumbing applications. It connects various lines that transport fluids throughout the engine system, including fuel lines, brake lines, and hydraulic systems. The connector’s robust construction ensures durability under high pressure and temperature conditions, providing reliable performance over the engine’s lifespan 1.

Integration with Turbocharger Systems

When integrated with turbocharger systems, the Banjo Connector plays a significant role in the oil feed and return lines. It ensures that the turbocharger receives the necessary lubrication to operate smoothly and reduce wear. The connector’s ability to create a tight seal prevents oil leaks, which could lead to contamination and decreased performance of the turbocharger 2.

Enhanced System Reliability

The use of the Banjo Connector in these systems enhances overall reliability by providing a consistent and secure connection point. This reduces the likelihood of fluid leaks, which can cause system failures and necessitate costly repairs. Additionally, the connector’s design allows for straightforward inspection and maintenance, contributing to the longevity and efficiency of the engine system 3.

Conclusion

The 5263691 Banjo Connector by Cummins is a vital component in the maintenance and operation of commercial truck fluid systems. Its robust design, precise engineering, and ease of installation make it an invaluable part for ensuring the efficiency, safety, and reliability of engine systems. Regular maintenance and proper installation are key to maximizing the lifespan and performance of this part.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.