This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

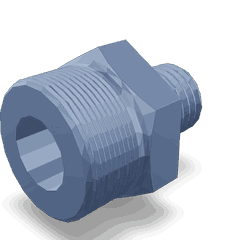

The Coupling Nipple 4989856 is a component manufactured by Cummins, a well-established name in the commercial truck industry. This part is designed for use in commercial trucks, where it plays a specific role in the vehicle’s fluid systems. Understanding its function and application is key to maintaining the efficiency and reliability of truck operations.

Basic Concepts of Coupling Nipples

A coupling nipple is a short pipe fitting used to connect two sections of pipe or other fluid-carrying components. Its general function in fluid systems is to provide a secure and leak-proof connection, allowing for the transfer of fluids such as fuel, coolant, or hydraulic fluid. Within a truck’s infrastructure, coupling nipples are vital for ensuring that fluid systems operate smoothly and without interruption 1.

Purpose of Coupling Nipple 4989856

The Coupling Nipple 4989856 serves a specific purpose in the operation of a truck. It is used to connect different components or systems, facilitating the flow of fluids between them. This part ensures that connections are secure and that fluid transfer is efficient, contributing to the overall performance of the truck.

Key Features

The Coupling Nipple 4989856 is notable for several characteristics that enhance its performance and durability. It is made from high-quality materials that resist corrosion and wear, ensuring long-term reliability. Its design includes precise threading and sealing surfaces that provide a tight fit, minimizing the risk of leaks. Additionally, it may feature unique attributes such as anti-vibration properties or easy-to-use connection mechanisms that further improve its functionality 2.

Benefits

Using the Coupling Nipple 4989856 offers several advantages. It contributes to improved efficiency in fluid transfer systems, ensuring that fluids move smoothly and without interruption. Its reliable design reduces the likelihood of leaks or failures, enhancing the overall reliability of the truck. Furthermore, its durability can lead to cost savings by reducing the need for frequent replacements or repairs.

Installation and Usage

Proper installation of the Coupling Nipple 4989856 is crucial for ensuring optimal performance and longevity. It should be installed according to manufacturer guidelines, which may include specific torque settings for tightening and the use of appropriate sealants or gaskets. Careful attention to these details during installation will help prevent issues such as leaks or loose connections.

Troubleshooting and Maintenance

Common issues with the Coupling Nipple 4989856 may include leaks, corrosion, or damage from vibration. Regular inspection and maintenance can help identify these issues early, allowing for timely repairs or replacements. Diagnostic tips may involve checking for signs of wear or corrosion, ensuring connections are tight, and verifying that fluid flow is consistent. Maintenance practices should include cleaning the fitting and surrounding areas, applying appropriate sealants or lubricants, and replacing the part if significant wear or damage is detected 3.

Safety Considerations

When working with the Coupling Nipple 4989856, it is important to observe safety protocols to prevent accidents or injuries. This includes wearing appropriate personal protective equipment, ensuring that the truck is properly shut down and depressurized before beginning work, and following all manufacturer guidelines for installation and maintenance. Additionally, being aware of the potential hazards associated with fluid systems, such as high pressure or toxic substances, is crucial for safe operation.

Cummins Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes a wide range of power solutions, including engines, filtration, and fluid power systems. With a history spanning over a century, Cummins has established a strong reputation in the commercial truck industry for producing reliable, high-performance components. Their product range includes engines, powertrain components, and aftermarket parts, all designed to meet the demanding requirements of commercial trucking applications.

Cummins Coupling Nipple 4989856 in Engine Applications

The Cummins Coupling Nipple 4989856 is a critical component in the engine systems of various Cummins engines. This part is designed to ensure a secure and reliable connection between different parts of the engine, facilitating the smooth transfer of fluids or gases. Its application is widespread across multiple engine models, ensuring compatibility and performance across the board.

B3.3 Engine Series

In the B3.3 engine series, the Coupling Nipple 4989856 plays a pivotal role in maintaining the integrity of the engine’s hydraulic or fuel systems. This engine series is known for its robust design and efficiency, and the coupling nipple is no exception in terms of quality and reliability. The precise fit and function of this part are crucial for the overall performance and longevity of the engine.

Grouping by Application

- Hydraulic Systems: In engines where hydraulic systems are integral, the coupling nipple ensures that there are no leaks or disconnections, which could lead to system failures.

- Fuel Systems: For engines that rely on precise fuel delivery, the coupling nipple guarantees that the fuel flow remains uninterrupted, contributing to the engine’s efficiency and power output.

The Cummins Coupling Nipple 4989856 is engineered to withstand the demanding conditions within engine environments, providing a dependable connection that is essential for the engine’s operation. Its design and material ensure that it can handle high pressures and temperatures, making it a vital component in the engine’s architecture.

Role of Part 4989856 Coupling Nipple in Engine Systems

The part 4989856 Coupling Nipple is an essential component in various engine systems, facilitating the seamless integration and operation of multiple subsystems.

Integration with Mounting Systems

In engine mounting systems, the Coupling Nipple ensures secure and stable connections between the engine and its supporting structure. This part allows for the transfer of mechanical forces while accommodating slight movements and vibrations, which are inherent in engine operation. The secure fit provided by the Coupling Nipple helps maintain alignment and reduces the risk of component fatigue or failure over time.

Functionality in Front Gear Train Accessory Systems

When incorporated into front gear train accessory systems, the Coupling Nipple plays a significant role in transmitting power efficiently. It connects various accessories, such as alternators, power steering pumps, and air conditioning compressors, to the engine’s front gear train. This connection ensures that these accessories receive the necessary power to function correctly, contributing to the overall performance and reliability of the engine system.

Application in Plumbing Systems

In plumbing systems within engine compartments, the Coupling Nipple is used to join different sections of hoses and pipes. This application is particularly important in cooling systems, where it ensures a leak-free connection between the radiator, thermostat housing, and other cooling components. The Coupling Nipple’s design allows for easy installation and removal, facilitating maintenance and repairs.

Role in Air Fuel Control Systems

The Coupling Nipple is also vital in air fuel control systems, where it connects various sensors and actuators to the engine’s intake and exhaust systems. This part ensures that the air-fuel mixture is accurately measured and controlled, which is essential for optimal engine performance and emissions compliance. The Coupling Nipple’s precise fit and sealing properties help maintain the integrity of the air fuel control system, ensuring consistent and efficient engine operation.

Conclusion

The Coupling Nipple 4989856 by Cummins is a critical component in the fluid systems of commercial trucks and engines. Its design, material, and precise fit ensure reliable and efficient fluid transfer, contributing to the overall performance and reliability of the vehicle. Proper installation, regular maintenance, and adherence to safety protocols are essential for maximizing the benefits of this part.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.