This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

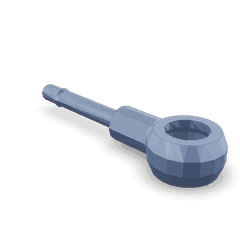

The Cummins 4982263 Banjo Connector is a specialized component designed for use in commercial trucks. It plays a significant role in the operation of these vehicles by facilitating the connection between various fluid systems and components. Understanding its purpose and functionality is key to maintaining the efficiency and reliability of truck operations.

Basic Concepts of Banjo Connectors

A banjo connector is a type of fitting used in fluid systems to join two components, typically hoses or pipes, to a port on a machine. It consists of a short, tubular body with fittings on each end, one of which is usually a bolt or a nut that screws into a port. In the context of heavy-duty trucks, banjo connectors are integral to the hydraulic and fuel systems, ensuring secure and leak-free connections that can withstand high pressures and dynamic conditions 1.

Purpose of the Cummins 4982263 Banjo Connector

This Cummins part is specifically designed to play a role in the hydraulic or fuel system of a truck. It provides a secure connection point for hoses or pipes, allowing for the transfer of fluids under pressure. This component is engineered to ensure that the connection remains intact and sealed, even under the demanding conditions typical of commercial truck operations.

Key Features

The Cummins 4982263 Banjo Connector is constructed with precision to meet the rigorous demands of heavy-duty applications. It is made from high-quality materials that offer durability and resistance to corrosion. The design includes specific connection types that are compatible with various hose and pipe configurations, ensuring a versatile fit. Additionally, unique attributes such as reinforced seals and precision machining enhance its performance and reliability 2.

Benefits

The Cummins 4982263 Banjo Connector offers several advantages. Its design contributes to improved sealing, reducing the risk of leaks in the system. The ease of installation is another benefit, allowing for quick and efficient setup without the need for specialized tools. Furthermore, its durability ensures long-term performance, and its resistance to corrosion and high pressures makes it suitable for the harsh environments encountered by commercial trucks.

Installation and Usage

Proper installation of the Cummins 4982263 Banjo Connector is vital for optimal performance. It is recommended to follow specific torque specifications provided by the manufacturer to ensure the connection is secure without overtightening, which could damage the fitting or the connected components. Adhering to recommended practices, such as cleaning the connection points and inspecting for damage before installation, will help maintain the integrity of the system 3.

Troubleshooting and Maintenance

Common issues with banjo connectors may include leaks, corrosion, or damage to the fitting. Diagnostic steps for identifying problems involve inspecting the connection for signs of wear, checking for fluid leaks, and ensuring that the fitting is properly torqued. Regular maintenance, such as cleaning the connection points and replacing worn seals, can help prolong the lifespan of the component and ensure continued reliable operation.

Safety Considerations

When working with the Cummins 4982263 Banjo Connector, it is important to observe safety practices and precautions. This includes handling the component with care to avoid damage, using appropriate personal protective equipment, and performing system checks to ensure that all connections are secure and leak-free before operating the vehicle. Adhering to these safety considerations helps protect both the equipment and the individuals working on it.

Cummins Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. With a history spanning over a century, Cummins has established a reputation for quality and innovation in the commercial truck industry. Its extensive product range includes engines, powertrains, and aftermarket parts, all designed to meet the demanding requirements of heavy-duty applications.

Role of the 4982263 Banjo Connector in Engine Systems

Plumbing Integration

The 4982263 Banjo Connector is instrumental in the plumbing of engine systems. It facilitates the secure connection between hoses and fittings, ensuring a leak-free pathway for fluids such as oil, coolant, and hydraulic fluid. This part is typically used in high-pressure systems where maintaining a consistent flow is essential. The Banjo Connector’s design allows for easy attachment and detachment, which is beneficial during maintenance or repairs. It also ensures that the connections remain tight under varying pressure conditions, which is vital for the efficient operation of the engine.

Air Fuel Control System

In the context of the Air Fuel Control (AFC) system, the 4982263 Banjo Connector plays a significant role in managing the delivery of fuel and air to the engine. It connects various components such as fuel injectors, fuel rails, and vacuum lines. The secure fitting provided by the Banjo Connector ensures that there are no leaks in the AFC system, which could otherwise lead to inefficient combustion and reduced engine performance. Additionally, it helps in maintaining the precise mixture of air and fuel, which is essential for optimal engine operation and emissions control. The Banjo Connector’s robust construction ensures that it can withstand the high pressures and temperatures within the AFC system, contributing to the overall reliability and efficiency of the engine.

Conclusion

The Cummins 4982263 Banjo Connector is a vital component in the maintenance and operation of commercial trucks. Its design and features ensure secure, leak-free connections in high-pressure fluid systems, contributing to the efficiency and reliability of truck operations. Proper installation, regular maintenance, and adherence to safety practices are essential for maximizing the performance and lifespan of this Cummins part.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.