This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

The Cummins 4968785 Banjo Connector is a specialized component designed for use in commercial trucks. It plays a role in the operation of these vehicles by facilitating the secure connection of hydraulic or fuel lines. Understanding its purpose and functionality is key to maintaining the efficiency and reliability of truck systems.

Basic Concepts of Banjo Connectors

A banjo connector is a type of fitting used in fluid systems to join two pipes or hoses. It typically consists of a short, cylindrical body with threaded ends and a sealing gasket. In the context of a truck’s hydraulic or fuel system, the banjo connector allows for the transfer of fluids under pressure while providing a sealed connection that prevents leaks 1.

Purpose of the 4968785 Banjo Connector

This Cummins part is specifically designed to play a role in the operation of commercial trucks by connecting hydraulic or fuel lines. Its application ensures that the fluid systems within the truck operate efficiently, with minimal risk of leaks or connection failures.

Key Features

The 4968785 is constructed using high-quality materials that enhance its performance and durability. Its design includes a robust sealing mechanism that ensures a tight connection, reducing the likelihood of fluid leaks. Additionally, the connector is engineered to withstand the pressures and temperatures typical of truck fluid systems 2.

Benefits

This part offers several advantages. Its design allows for improved sealing compared to other types of connectors, which contributes to the overall efficiency of the fluid system. Additionally, it is designed for ease of installation, which can save time during maintenance procedures. The connector also provides maintenance benefits, such as simplified inspection and cleaning processes.

Installation Process

Installing the 4968785 requires the use of specific tools and adherence to best practices to ensure a secure and leak-free connection. The process involves preparing the connection points, applying the appropriate sealing compound, and tightening the connector to the specified torque. Careful attention to these steps is necessary to achieve optimal performance 3.

Troubleshooting Common Issues

Typical problems that may arise with this part include leaks or connection failures. These issues can often be identified through visual inspection and pressure testing. Solutions may involve re-tightening the connector, replacing the sealing gasket, or, in some cases, replacing the connector itself.

Maintenance Tips

Regular maintenance of the 4968785 is important for prolonging its service life. This includes periodic inspection for signs of wear or damage, cleaning the connector and surrounding areas to prevent contamination, and replacing the gasket as needed. Adhering to these maintenance practices can help ensure the continued reliability of the fluid system.

Compatibility and Applications

The 4968785 is designed for use in specific types of trucks and systems. It is commonly applied in models where reliable fluid connections are critical to operation. Understanding the compatibility of this connector with various truck systems is important for ensuring proper function and performance.

Cummins: A Brief Overview

Cummins Inc. is a well-established company in the commercial truck industry, known for its range of high-quality products. The company’s history, diverse product offerings, and strong reputation contribute to the trust placed in components like the 4968785. This background underscores the quality and reliability that Cummins products are known for in the industry.

Engine Compatibility of Part 4968785

This part is designed to fit seamlessly within a range of Cummins engine models. It is integral for ensuring proper fluid transfer and pressure maintenance in the engine systems.

QSK19 CM2350 K114 and QSK19 CM850 MCRS

For the QSK19 CM2350 K114 and QSK19 CM850 MCRS engines, the Banjo Connector is engineered to integrate with the engine’s fluid lines. This ensures that the connectors maintain a secure and leak-proof seal, which is crucial for the efficient operation of the engine. The design of the part allows for easy installation and removal, facilitating maintenance and repairs.

QSK19 CM2350 K114

In the QSK19 CM2350 K114 engine, the Banjo Connector is specifically tailored to fit the unique fluid line configurations of this model. Its robust construction ensures that it can withstand the operational stresses and pressures within the engine system, providing long-lasting reliability.

QSK19 CM850 MCRS

Similarly, for the QSK19 CM850 MCRS engine, the part is designed to match the precise specifications of the engine’s fluid lines. This ensures that the connector performs optimally, maintaining the integrity of the fluid pathways and contributing to the overall efficiency and performance of the engine.

By ensuring compatibility with these specific engine models, the Banjo Connector plays a vital role in the maintenance and functionality of the engines, providing a reliable solution for fluid management.

Role of Part 4968785 Banjo Connector in Engine Systems

The Banjo Connector is integral to the efficient operation of several engine components. Its primary function is to facilitate the secure and leak-proof connection between various parts, ensuring the smooth flow of fluids such as lubricating oil.

Connection to the Filter

In engine systems, the Banjo Connector is often used to link the lubricating oil filter to the engine block or other components. This connection is vital for maintaining the integrity of the oil filtration process. The Banjo Connector ensures that lubricating oil flows consistently through the filter, capturing contaminants and maintaining oil cleanliness. This, in turn, supports the longevity and performance of the engine by reducing wear on moving parts.

Integration with Lubricating Oil System

The Banjo Connector plays a significant role in the lubricating oil system by providing a reliable connection point for oil lines. It is commonly used to connect the oil supply line to the filter head, ensuring that lubricating oil is delivered efficiently to all necessary engine components. This connection is designed to withstand the pressure and temperature variations within the engine, maintaining a stable oil flow that is essential for proper lubrication.

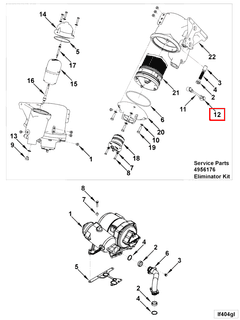

Use in Filter Kits

When installing a filter kit, the Banjo Connector is often included to simplify the replacement process. It allows for a quick and secure connection between the new filter and the engine, reducing the risk of oil leaks during installation. This feature is particularly beneficial during maintenance procedures, where minimizing downtime and ensuring a leak-free system are paramount.

Connection to Lubricating Oil Filter Head

The Banjo Connector is also utilized to connect the lubricating oil filter head to the engine. This connection is critical for the proper functioning of the filter head, which houses the filter element and regulates oil flow. The secure fitting provided by the Banjo Connector ensures that the filter head operates efficiently, contributing to the overall effectiveness of the oil filtration system.

Conclusion

In summary, the 4968785 Banjo Connector is a key component in maintaining the integrity and efficiency of the engine’s lubricating oil system. Its reliable connections support the consistent flow of lubricating oil, enhancing engine performance and durability.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.