4966905

Jumper Connector

Cummins®

AVAILABLE

8 are currently available

Ships within 2-4 business days

This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

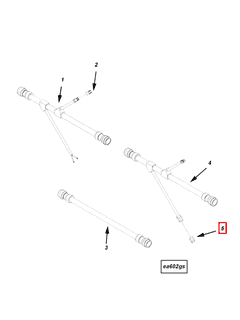

The Cummins 4966905 Jumper Connector is a specialized component designed for use in the electrical systems of commercial trucks. It serves as a vital tool for technicians and fleet managers, facilitating efficient diagnostics and providing temporary wiring solutions. Its role in maintaining the operational integrity of truck electrical systems underscores its significance in the commercial trucking industry.

Purpose and Functionality

The 4966905 Jumper Connector is integral to the electrical system of a truck, primarily used during diagnostic procedures and for temporary wiring needs. It allows technicians to bypass certain electrical components or circuits, enabling them to isolate issues and perform tests without disrupting the entire system. This connector is particularly useful in troubleshooting complex electrical problems, ensuring that diagnostics can be conducted swiftly and accurately 1.

Key Features

The design and construction of the 4966905 Jumper Connector are tailored for durability and performance. Crafted from high-quality materials, it is built to withstand the harsh conditions often encountered in commercial trucking environments. Its robust construction ensures reliable connectivity and longevity, while unique characteristics such as corrosion-resistant coatings enhance its performance in demanding applications 2.

Benefits

Utilizing the 4966905 Jumper Connector offers several advantages. It significantly improves diagnostic efficiency by allowing for quick and precise testing of electrical components. Its reliability in harsh environments ensures consistent performance, even under challenging conditions. Additionally, the connector is designed for ease of use, facilitating straightforward installation and operation for technicians 3.

Installation and Usage

Proper installation and usage of the 4966905 Jumper Connector involve several steps to ensure optimal performance and safety. Begin by identifying the specific electrical circuit or component that requires testing. Connect the jumper connector to the appropriate terminals, ensuring a secure fit. Conduct the necessary diagnostic tests, then carefully remove the connector once testing is complete. Adhere to best practices, such as wearing appropriate personal protective equipment (PPE) and following safety guidelines to prevent accidents.

Troubleshooting and Maintenance

Common issues with the 4966905 Jumper Connector may include poor connectivity or damage to the connector itself. Troubleshooting involves checking for secure connections and inspecting the connector for signs of wear or corrosion. Regular maintenance, such as cleaning the connector terminals and ensuring they are free from debris, is recommended to maintain optimal performance and longevity.

Safety Considerations

When using the 4966905 Jumper Connector, it is important to follow safety guidelines to prevent accidents and ensure user safety. Always wear appropriate PPE, including insulated gloves and safety glasses. Ensure the truck’s electrical system is de-energized before connecting or disconnecting the jumper connector to avoid electrical shocks. Additionally, store the connector in a dry, secure location to protect it from damage and contamination.

Cummins Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes a wide range of power solutions, including engines, filtration, and emissions technologies. With a history spanning over a century, Cummins has established a reputation for quality and innovation in the commercial truck industry. The company’s commitment to excellence is evident in its products, which are designed to meet the demanding requirements of commercial trucking applications.

Jumper Connector 4966905 Compatibility with Cummins Engines

The Jumper Connector 4966905, manufactured by Cummins, is designed to integrate seamlessly with a variety of Cummins engines, ensuring reliable electrical connections and optimal performance. This part is compatible with the following engine models:

- QSK19 CM850 MCRS

- QSK50 CM2150 K107

- QSK50 CM2150 MCRS

- QSK60 CM850 MCRS

The compatibility of the Jumper Connector 4966905 across these engines underscores its versatility and importance in maintaining the integrity of the electrical systems within these engines.

For the QSK19 CM850 MCRS and QSK60 CM850 MCRS engines, the connector ensures that the electrical pathways are correctly established, facilitating smooth operation and reducing the risk of electrical faults.

In the QSK50 CM2150 K107 and QSK50 CM2150 MCRS engines, the Jumper Connector 4966905 plays a crucial role in connecting various electrical components, ensuring that the engine’s control systems and auxiliary functions are properly powered and controlled.

This part’s design and functionality make it an essential component for maintaining the operational efficiency and reliability of these Cummins engines.

Role of Part 4966905 Jumper Connector in Engine Systems

The Jumper Connector, identified as part 4966905, serves as an essential link in various engine systems, facilitating seamless communication and functionality among different components.

In the Engine Monitoring System (EMS), the Jumper Connector ensures that all sensors and monitoring devices are correctly interfaced with the central processing unit. This allows for accurate data collection and real-time monitoring of engine performance metrics, such as temperature, pressure, and fuel efficiency. The Jumper Connector enables the EMS to maintain optimal engine operation by providing a reliable pathway for data transmission.

When integrated with the Main Extension Harness, the Jumper Connector plays a pivotal role in extending the reach of the primary wiring system. This extension is vital for connecting remote sensors and actuators that are not located near the main engine control unit. The Jumper Connector ensures that these extended components receive the necessary power and data signals, thereby enhancing the overall functionality and responsiveness of the engine system.

In conjunction with the Wiring Harness, the Jumper Connector acts as a bridging element that simplifies the routing of electrical connections. It allows for flexible and modular wiring configurations, which are particularly beneficial during engine maintenance or upgrades. The Jumper Connector helps in reducing the complexity of the wiring layout, making it easier to diagnose and resolve electrical issues. Additionally, it supports the addition of new components or the reconfiguration of existing ones without requiring a complete overhaul of the wiring harness.

Overall, the Jumper Connector (part 4966905) is instrumental in maintaining the integrity and efficiency of engine systems by ensuring robust and adaptable electrical connections across various components.

Conclusion

The Cummins 4966905 Jumper Connector is a critical component in the maintenance and diagnostics of commercial truck electrical systems. Its robust design, ease of use, and compatibility with various Cummins engines make it an invaluable tool for technicians and fleet managers. By ensuring reliable electrical connections and facilitating efficient diagnostics, this part plays a significant role in maintaining the operational integrity of truck electrical systems.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.