4956322

Flexible Coupling

Cummins®

AVAILABLE

3 are currently available

Ships within 2-4 business days

This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

The 4956322 Flexible Coupling, a component manufactured by Cummins, is designed for use in commercial trucks. This part is integral to the mechanical systems of trucks, facilitating the connection between various components and ensuring efficient power transmission. Flexible couplings like the 4956322 accommodate misalignment, reduce stress on connected components, and enhance the overall reliability of the mechanical system 1.

Basic Concepts of Flexible Couplings

Flexible couplings are devices used to connect two shafts in a mechanical system, allowing for a degree of misalignment and providing a means for torque transmission while dampening vibrations. They operate by transmitting rotational force from one shaft to another, accommodating small angular, parallel, and axial misalignments. This capability is vital in maintaining the integrity and efficiency of mechanical systems, particularly in heavy-duty applications where vibrations and misalignments are common 2.

Purpose of the 4956322 Flexible Coupling in Truck Operations

In the operation of commercial trucks, the 4956322 Flexible Coupling connects different components of the drivetrain, such as the engine and transmission, or the transmission and differential. It facilitates efficient power transmission by allowing for slight misalignments between these components, which can occur due to thermal expansion, wear, or manufacturing tolerances. This coupling ensures that power is transmitted smoothly and efficiently, reducing the risk of damage to the connected components and enhancing the truck’s overall performance and reliability 3.

Key Features of the 4956322 Flexible Coupling

The 4956322 Flexible Coupling boasts several key features that enhance its performance and durability. It is constructed from high-quality materials, ensuring resistance to wear and corrosion. Its design incorporates elements that allow for significant misalignment compensation, reducing stress on the connected shafts. Additionally, the coupling features a robust housing that protects the internal components from contaminants and external damage, contributing to its longevity in demanding truck applications.

Benefits of Using the 4956322 Flexible Coupling

Incorporating the 4956322 Flexible Coupling into truck systems offers several advantages. It improves the reliability of the drivetrain by accommodating misalignments and reducing the stress on connected components. This results in reduced maintenance needs, as the coupling helps prevent premature wear and failure of shafts and bearings. Furthermore, the efficient power transmission facilitated by the coupling enhances the truck’s performance, contributing to smoother operation and potentially improving fuel efficiency.

Installation Considerations

When installing the 4956322 Flexible Coupling, it is important to follow guidelines and best practices to ensure proper function and longevity. This includes using the necessary tools for alignment and torque specifications, ensuring that the coupling is correctly aligned with the shafts it connects. Common pitfalls during installation, such as over-torquing or misalignment, should be avoided to prevent damage to the coupling and connected components.

Troubleshooting Common Issues

Common problems associated with flexible couplings include misalignment, wear, and failure symptoms such as unusual noises or vibrations. Troubleshooting these issues involves identifying the source of the problem, whether it be incorrect installation, excessive wear, or external damage. Solutions may range from realigning the coupling to replacing worn components, ensuring that the coupling continues to function efficiently.

Maintenance Tips

Regular maintenance practices are key to ensuring the longevity and optimal performance of the 4956322 Flexible Coupling. This includes routine inspections for signs of wear or damage, cleaning the coupling to remove contaminants, and following lubrication guidelines to reduce friction and wear. Adhering to these maintenance tips helps prevent unexpected failures and extends the service life of the coupling.

Cummins: A Brief Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. With a history spanning over a century, Cummins has established a reputation for quality and innovation in the commercial truck industry. The company’s commitment to excellence is evident in its wide range of products, including the 4956322 Flexible Coupling, which embodies Cummins’ dedication to providing reliable and high-performance components for the demanding environments of commercial trucking.

Flexible Coupling 4956322 Compatibility with Cummins Engines

The Cummins Flexible Coupling part number 4956322 is designed to fit a variety of Cummins engines, ensuring smooth and reliable power transmission. This coupling is engineered to accommodate the unique characteristics of each engine model, providing flexibility and durability in various applications.

QSK50 Series

The QSK50 series engines, specifically the QSK50 CM2150 K107 and QSK50 CM2150 MCRS, are well-suited for the 4956322 Flexible Coupling. This coupling is engineered to handle the specific torque and rotational demands of these engines, ensuring efficient power transfer and reducing the risk of mechanical failure.

QSK60 Series

For the QSK60 CM850 MCRS engine, the 4956322 Flexible Coupling is an ideal match. This engine model requires a coupling that can manage higher torque levels and rotational speeds, and the 4956322 is designed to meet these requirements, providing a reliable connection between the engine and the driven equipment.

QSK95 Series

The QSK95 series engines, including the QSK95 CM2350 K111 and QSK95 CM2350 K113, also benefit from the use of the 4956322 Flexible Coupling. These engines are known for their robust performance and high power output, and the coupling is designed to handle the associated stresses and vibrations, ensuring long-term durability and performance.

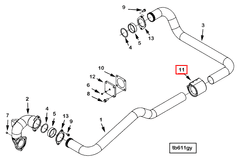

Role of the 4956322 Flexible Coupling in Engine Systems

The 4956322 Flexible Coupling is an integral component in the seamless operation of various engine systems, particularly within the auxiliary cooling system. Its primary function is to facilitate a secure yet flexible connection between the auxiliary cooling inlet and the water outlet. This flexibility is essential for accommodating the slight movements and vibrations that occur during engine operation, ensuring that the connection remains intact and efficient.

In the context of the heat exchanger, the Flexible Coupling allows for the transfer of coolant between the engine housing and the thermostat system without the risk of leaks or disconnections. This is particularly important in maintaining the optimal temperature of the engine, as any disruption in the coolant flow could lead to overheating or inefficient cooling.

Furthermore, the Flexible Coupling plays a significant role in the overall integrity of the auxiliary cooling system. By providing a robust yet adaptable connection, it ensures that the system can handle the dynamic conditions within the engine environment. This not only enhances the performance of the cooling system but also contributes to the longevity and reliability of the engine components.

Conclusion

The 4956322 Flexible Coupling is a key element in ensuring the efficient and reliable operation of the auxiliary cooling system, facilitating smooth and secure connections between critical components. Its design and features make it a versatile and durable component suitable for various Cummins engines, contributing to the overall performance and reliability of commercial trucks.

-

Advanced Automotive Electricity and Electronics, Michael Klyde and Kirk VanGelder, Jones Bartlett Learning, 2010.

↩ -

Bosch Automotive Electrics and Automotive Electronics: Systems and Components, Networking and Hybrid Drive 5th Edition, Robert Bosch GmbH, Springer Vieweg, 2007.

↩ -

The Vehicle Diesel Engine Startup Process Operational and Environmental Aspects, Pawel Drozdziel, Routledge, 2023.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.