4941313

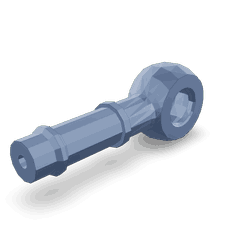

Banjo Connector

Cummins®

IN STOCK

More than 10 are currently available

Ships within 1 business day

This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

The Cummins 4941313 Banjo Connector is a specialized component designed for use in heavy-duty truck systems. Its purpose is to facilitate secure connections in fluid systems, ensuring efficient operation and reliability. This connector is significant due to its role in maintaining the integrity of hydraulic and fuel systems within trucks.

Basic Concepts of Banjo Connectors

A banjo connector is a type of fitting used in fluid systems to connect hoses or pipes to various components. It typically consists of a bolt, a banjo fitting, and a pair of washers. The banjo fitting is a short, tubular component with an opening on one end and a threaded bolt on the other. When tightened, the bolt compresses the washers against the hose or pipe, creating a seal that prevents fluid leakage. In the context of a truck’s hydraulic or fuel system, banjo connectors play a vital role in ensuring that fluid transfer is efficient and secure 1.

Purpose of the 4941313 Banjo Connector

The 4941313 Banjo Connector is specifically designed to connect hoses or pipes to fittings within a truck’s system. It ensures a tight seal, which is crucial for maintaining the pressure and flow of fluids such as hydraulic oil or fuel. By providing a reliable connection point, this connector contributes to the overall efficiency and safety of the truck’s operation.

Key Features

The 4941313 Banjo Connector boasts several key features that enhance its performance and durability. Its design includes precision-machined components to ensure a perfect fit and optimal sealing. The materials used are typically high-grade steel or stainless steel, which offer excellent resistance to wear and corrosion. Additionally, the connector may feature unique characteristics such as reinforced washers or specialized coatings to further improve its longevity and reliability.

Benefits

The 4941313 Banjo Connector offers several benefits that make it a valuable component in heavy-duty truck systems. Improved sealing is one of the primary advantages, as it helps prevent leaks that could lead to system failures or safety hazards. The ease of installation is another benefit, allowing for quick and efficient connections without the need for complex tools. Furthermore, its resistance to wear and corrosion ensures that the connector remains functional even under demanding conditions.

Installation and Usage

Proper installation of the 4941313 Banjo Connector involves several steps to ensure a secure and leak-free connection. Begin by cleaning the connection points to remove any debris or contaminants. Next, apply a compatible sealant to the threads of the banjo bolt if required. Position the banjo fitting over the hose or pipe and align it with the corresponding fitting on the component. Tighten the banjo bolt using the appropriate torque specifications to compress the washers and create a seal. Finally, inspect the connection for any signs of leakage and make adjustments as necessary.

Troubleshooting and Maintenance

Common issues with the 4941313 Banjo Connector may include leaks or corrosion. To troubleshoot leaks, first, ensure that the banjo bolt is tightened to the correct torque specification. If leaks persist, inspect the washers for damage or wear and replace them if necessary. Corrosion can be addressed by cleaning the affected areas with a suitable solvent and applying a protective coating. Regular maintenance, such as periodic inspection and tightening of the banjo bolt, can help prolong the lifespan of the connector.

Safety Considerations

When working with the 4941313 Banjo Connector, it is important to observe several safety guidelines and precautions. Always wear appropriate personal protective equipment, such as gloves and safety glasses, to protect against potential hazards. Handle the connector with care to avoid damage to the fitting or threads. Store the connector in a dry, clean environment to prevent corrosion. Additionally, follow proper disposal procedures for any used components or sealants to minimize environmental impact.

Cummins Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes a wide range of power solutions, including engines, filtration, and emissions solutions. With a history dating back to 1919, Cummins has established a strong reputation for innovation, quality, and reliability in the automotive and heavy-duty truck industry. The company’s product range includes engines, powertrains, and related components that are designed to meet the demanding requirements of various applications.

Cummins Engine Part 4941313: Banjo Connector Compatibility

The Cummins part 4941313, a Banjo Connector, is designed to fit a variety of Cummins engines. This part is integral in ensuring the proper sealing and connection of hydraulic or fuel lines, providing a reliable method to attach these lines to the engine’s fuel or hydraulic systems.

F4.5 CM2620 and F141C

The Banjo Connector part 4941313 is compatible with the F4.5 CM2620 and F141C engines. These engines are known for their robust performance and are often used in heavy-duty applications.

ISB (Chrysler), ISC CM2150, ISC8.3 CM2250

The ISB (Chrysler) engine, along with the ISC CM2150 and ISC8.3 CM2250, also utilize the part 4941313. These engines are typically found in various commercial and industrial applications, providing a balance of power and efficiency.

ISL CM2150, ISL9 CM2150 SN, ISL9 CM2250

The ISL CM2150, ISL9 CM2150 SN, and ISL9 CM2250 engines are another set of engines that are compatible with the Banjo Connector part 4941313. These engines are known for their durability and are often used in demanding environments.

QSB4.5 CM2250 EC, QSB6.7 CM2250, QSB6.7 CM2350 B105

The QSB4.5 CM2250 EC, QSB6.7 CM2250, and QSB6.7 CM2350 B105 engines are also designed to work with the part 4941313. These engines are widely used in agricultural and construction machinery, providing reliable power and performance.

QSC9 CM2250/QSL9 CM2250, QSL9 CM2250, QSL9 CM2350 L102

Lastly, the QSC9 CM2250/QSL9 CM2250, QSL9 CM2250, and QSL9 CM2350 L102 engines are compatible with the Banjo Connector part 4941313. These engines are often found in heavy-duty trucks and industrial equipment, offering a combination of power and efficiency.

Role of Part 4941313 Banjo Connector in Engine Systems

The 4941313 Banjo Connector is integral to the efficient operation of various engine systems by facilitating secure and reliable fluid connections. It is commonly employed in the following applications:

-

Exhaust Cooler Water Outlet Tube: The Banjo Connector ensures a leak-free connection between the exhaust cooler and the water outlet tube. This is essential for maintaining the integrity of the cooling system and ensuring that the exhaust gases are effectively cooled before entering the atmosphere.

-

Hardware Kit: When included in a hardware kit, the Banjo Connector provides a standardized fitting that can be used across different components, simplifying the installation process and ensuring consistent performance.

-

Location: Proper placement of the Banjo Connector is key to its function. It is often situated in areas where fluid lines need to be connected securely, such as between the radiator and the engine block, or within the turbocharger system.

-

Corrosion Resistor: The Banjo Connector is typically made from materials that resist corrosion, which is vital for longevity in environments where exposure to coolants and other fluids is constant.

-

Plumbing: In the context of engine plumbing, the Banjo Connector plays a role in connecting various fluid lines, ensuring that coolant, oil, and other fluids are routed correctly throughout the engine system.

-

Exhaust Recirculation Water: For systems that recirculate water within the exhaust system, the Banjo Connector provides a reliable connection point, helping to manage temperatures and improve overall engine efficiency.

-

Radiator: Connecting the radiator to other components, the Banjo Connector helps maintain the flow of coolant, which is essential for dissipating heat and keeping the engine within optimal operating temperatures.

-

Turbocharger Cool Drain / Vent Tube: In turbocharged engines, the Banjo Connector is used to connect the cool drain or vent tube, allowing for the efficient removal of condensate and ensuring that the turbocharger operates smoothly.

-

Upfit Kit: When engines are upgraded or modified, the Banjo Connector can be part of an upfit kit, providing necessary connections for additional components such as aftermarket intercoolers or performance radiators.

-

Vent: The Banjo Connector may also be used in venting systems to ensure that pressure is released safely and efficiently from various engine compartments.

-

Engine Coolant: Finally, the Banjo Connector is often used in the engine coolant system to connect hoses and fittings, ensuring that coolant circulates effectively to regulate engine temperature.

Conclusion

The Cummins 4941313 Banjo Connector is a critical component in heavy-duty truck systems, ensuring secure and reliable fluid connections. Its design, featuring precision-machined components and high-grade materials, contributes to its durability and efficiency. Proper installation and maintenance are essential to maximize its benefits and ensure the longevity of the connector. By understanding its role and applications, technicians can effectively utilize this Cummins part to enhance the performance and reliability of truck engines.

-

Robinson, Alan, and Andrew Livesey. The Repair of Vehicle Bodies Fifth Edition. Elsevier, 2006.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.