This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

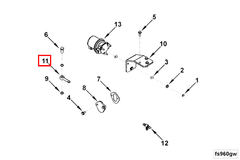

The 4940943 Banjo Bolt Connector, manufactured by Cummins, is a component designed for use in the commercial truck industry. Cummins, a well-established name in the field, produces a range of parts and systems that contribute to the efficiency and reliability of commercial vehicles. This Cummins part is significant within this context, playing a role in the fluid systems of trucks.

Basic Concepts of Banjo Bolt Connectors

A Banjo Bolt Connector is a type of fitting used in fluid systems to connect hoses or pipes to various components. It typically consists of a bolt with an integrated fitting that allows for the secure attachment of hoses. Within a truck’s hydraulic or fuel system, the Banjo Bolt Connector facilitates the transfer of fluids under pressure, ensuring that the system operates efficiently and without leaks 1.

Purpose of the 4940943 Banjo Bolt Connector

The 4940943 Banjo Bolt Connector is designed to connect hoses or pipes to different components within a truck’s system. Its role is to provide a secure and leak-proof connection, allowing for the efficient transfer of fluids. This connector is integral to maintaining the integrity of the fluid system, ensuring that components receive the necessary fluids for operation.

Key Features

The 4940943 features a design that enhances its performance and durability. It is constructed from materials that are resistant to corrosion and wear, ensuring longevity in demanding environments. The connector’s design includes features that facilitate easy installation and maintenance, contributing to its overall effectiveness in fluid systems.

Benefits

The advantages of the 4940943 include improved sealing capabilities, which reduce the risk of leaks in the fluid system. Its design also allows for ease of installation, minimizing downtime during maintenance procedures. Additionally, the connector’s durability and resistance to corrosion contribute to lower maintenance requirements over time.

Installation Process

Proper installation of the 4940943 involves several steps to ensure a secure and leak-proof connection. It is important to follow manufacturer guidelines for torque specifications and to use the appropriate tools. Careful attention should be paid to the condition of the sealing surfaces to prevent leaks. Best practices include checking for proper alignment and ensuring that all components are clean and free of debris before installation.

Troubleshooting Common Issues

Frequent problems associated with Banjo Bolt Connectors, such as leaks or corrosion, can often be traced back to installation errors or environmental factors. Troubleshooting methods may include inspecting the connector for signs of wear or damage, checking the tightness of the connection, and ensuring that all components are compatible and in good condition. Addressing these issues promptly can help maintain the efficiency and safety of the fluid system.

Maintenance Tips

Regular maintenance practices for the 4940943 include periodic inspection for signs of wear, corrosion, or leaks. Cleaning the connector and its surrounding components can prevent buildup that may lead to issues. It is also beneficial to review and follow the manufacturer’s maintenance guidelines to ensure the longevity and reliable performance of the connector.

Safety Considerations

When working with the 4940943, it is important to observe safety guidelines and precautions. This includes ensuring that the system is depressurized before beginning any work to prevent injury from fluid under pressure. Proper handling of the connector and its components is crucial to maintain system integrity and safety.

Cummins: A Brief Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. With a history of innovation and quality, Cummins has established a reputation for reliability in the commercial truck industry. The company’s product range includes a variety of parts and systems that contribute to the efficiency and performance of commercial vehicles, underscoring the quality and reliability of the 4940943.

Cummins Banjo Bolt Connector 4940943 in Engine Applications

The Cummins Banjo Bolt Connector part number 4940943 is a component in various engine systems, ensuring secure and reliable connections for hydraulic or fuel lines. This part is designed to withstand the rigors of engine operation, providing a robust seal that prevents leaks and maintains system integrity.

Engine Compatibility

The 4940943 is compatible with several Cummins engine models, including:

- 6B5.9 Series: This engine series is known for its durability and efficiency, often used in heavy-duty applications. The 4940943 fits seamlessly into the hydraulic and fuel systems of these engines, ensuring optimal performance and longevity.

Application in Engine Systems

In the 6B5.9 engines, the 4940943 is typically used in the following systems:

- Fuel Lines: It provides a secure connection point for fuel lines, ensuring that fuel delivery remains consistent and uninterrupted.

- Hydraulic Lines: This part is also crucial in hydraulic systems, where it connects various hydraulic lines, maintaining the necessary pressure and flow for engine operation.

Installation and Maintenance

Proper installation of the 4940943 is essential to prevent leaks and ensure the engine operates efficiently. Maintenance involves regular inspection for wear and tear, ensuring the connector remains tight and secure. Any signs of leakage or damage should prompt immediate replacement to avoid potential engine issues.

Importance in Engine Performance

The 4940943 plays a role in the overall performance of the engine. Its ability to provide a reliable seal is crucial for maintaining system pressure and ensuring that the engine runs smoothly. This part’s design and material quality contribute to the engine’s reliability and efficiency, making it a key component in Cummins engine systems.

Role of Part 4940943 Banjo Bolt Connector in Engine Systems

The Banjo Bolt Connector, identified by part number 4940943, is a component in the assembly and operation of various engine systems, particularly those involving fluid transfer mechanisms such as fuel systems.

In the context of a Fuel Transfer Pump, the Banjo Bolt Connector is utilized to establish a secure and leak-proof connection between the pump and the fuel lines. This connection ensures that fuel is efficiently and safely transferred from the fuel tank to the engine’s fuel injection system. The Banjo Bolt Connector’s design allows for easy installation and removal, facilitating maintenance and repair procedures.

When integrated with a general Pump system, whether it be for fuel, oil, or other fluids, the Banjo Bolt Connector serves a similar function. It creates a reliable connection point that withstands the pressures and vibrations inherent in engine operation. This is particularly important in high-performance engines where fluid dynamics play a significant role in overall engine efficiency and reliability.

In Fuel Transfer applications, the Banjo Bolt Connector is often found at critical junctures where fuel lines intersect with various components such as filters, regulators, and injectors. Its role here is to maintain the integrity of the fuel pathway, ensuring that fuel is delivered consistently and without contamination.

Overall, the Banjo Bolt Connector is a fundamental component in ensuring the seamless operation of engine systems by providing robust and dependable connections in fluid transfer applications.

Conclusion

The 4940943 Banjo Bolt Connector is a vital component in the commercial truck industry, ensuring secure and reliable connections in fluid systems. Its design, durability, and ease of installation contribute to the efficiency and reliability of commercial vehicles. Regular maintenance and proper installation are key to maximizing the performance and longevity of this Cummins part.

-

Reif, Konrad, ed. Gasoline Engine Management Systems and Components. Springer Vieweg, 2015.

↩

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.