4918925

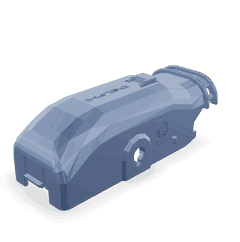

Connector Backshell

Cummins®

IN STOCK

More than 10 are currently available

Ships within 1 business day

This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

The Connector Backshell 4918925, manufactured by Cummins, is a specialized component designed for use in commercial trucks. Its primary role is to protect electrical connections within the vehicle’s systems, ensuring reliable and safe operation. Cummins, a well-established name in the automotive industry, is known for its commitment to producing high-quality components that enhance the performance and durability of commercial vehicles 1.

Basic Concepts of Connector Backshells

Connector backshells are protective coverings that encase electrical connectors. They serve multiple functions within an electrical system, including shielding connections from physical damage, reducing the risk of electrical interference, and protecting against environmental factors such as moisture, dust, and corrosion. By doing so, connector backshells contribute to the overall reliability and safety of truck operations, ensuring that electrical signals are transmitted accurately and efficiently 2.

Purpose of the 4918925 Connector Backshell

This Cummins part plays a specific role in the operation of a truck by safeguarding electrical connections. It is designed to fit over the connector, providing a barrier against external elements that could compromise the integrity of the electrical signal. This protection is vital for maintaining the performance of the truck’s electrical systems, ensuring that signals are transmitted without interference or degradation.

Key Features

The 4918925 Connector Backshell is characterized by several key features that enhance its functionality and durability. It is constructed from high-quality materials that offer superior protection against environmental factors. The design includes elements that ensure a secure fit over the connector, minimizing the risk of disconnection or damage. Additionally, the backshell may feature unique attributes such as strain relief mechanisms to further protect the electrical connections from physical stress.

Benefits

The use of the 4918925 Connector Backshell offers several benefits. It improves electrical performance by ensuring that connections remain secure and free from interference. The backshell provides enhanced protection against environmental factors, which can extend the longevity of electrical connections. This results in more reliable truck operations and reduced maintenance requirements over time.

Installation and Compatibility

Proper installation of the 4918925 Connector Backshell is crucial for optimal performance. It is designed to be compatible with a range of truck models, ensuring that it can be used in various applications. Specific installation procedures should be followed to ensure that the backshell is securely fitted and functions as intended. Compatibility with the truck’s electrical system and adherence to manufacturer guidelines are important considerations for achieving the best results 3.

Troubleshooting and Maintenance

Common issues with connector backshells may include damage from physical stress, environmental exposure, or improper installation. Troubleshooting steps involve inspecting the backshell for signs of wear or damage, ensuring that it is securely fitted, and checking for any signs of electrical interference. Regular maintenance practices, such as cleaning and inspecting the backshell, can help ensure continued reliable performance and prevent potential issues.

Safety Considerations

When working with electrical components like the 4918925 Connector Backshell, it is important to follow safety protocols. This includes proper handling of the component to avoid damage, conducting regular inspections to identify any issues early, and adhering to manufacturer guidelines for installation and maintenance. Safety considerations also involve ensuring that the electrical system is de-energized when performing maintenance or repairs to prevent electrical shock or other hazards.

Cummins Overview

Cummins is a reputable manufacturer in the automotive industry, known for its high-quality components that enhance the performance and durability of commercial vehicles. The company’s commitment to innovation and excellence is reflected in its wide range of products, including the 4918925 Connector Backshell. Cummins’ reputation for producing reliable and efficient components makes it a trusted choice for commercial truck operators and maintenance professionals.

Role of Part 4918925 Connector Backshell in Wiring Harness Repair Kit

This part is an essential component in the wiring harness repair kit, providing a secure and reliable connection between various electrical components within the engine system.

When integrated into the wiring harness repair kit, the 4918925 Connector Backshell ensures that the electrical connections are protected from environmental factors such as moisture, dust, and physical damage. This protection is vital for maintaining the integrity of the electrical signals transmitted through the wiring harness.

The backshell also plays a significant role in organizing and managing the wires within the harness. By enveloping the connector, it prevents wires from becoming tangled or frayed, which can lead to short circuits or intermittent connections. This organization is particularly important in high-vibration environments typical of engine compartments.

Furthermore, the 4918925 Connector Backshell aids in strain relief for the wires. As the engine operates, vibrations and movements can place stress on the wiring. The backshell absorbs some of this stress, reducing the likelihood of wire fatigue and breakage.

Conclusion

In summary, the 4918925 Connector Backshell enhances the durability, reliability, and performance of the wiring harness repair kit, ensuring that electrical connections within the engine system remain secure and efficient.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.