This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

The Cummins 3973033 Banjo Connector is a specialized component designed for use in commercial trucks. Its purpose is to facilitate the connection between hoses and pipes in hydraulic or fuel systems. The significance of this connector lies in its ability to ensure a secure and leak-free connection, which is vital for the efficient operation of these systems 1.

Basic Concepts of Banjo Connectors

A banjo connector is a type of fitting used in fluid systems to join hoses or pipes. It typically consists of a bolt, a banjo fitting, and a gasket. The banjo fitting has a curved shape that allows it to be bolted onto a flat surface, creating a sealed connection. In the context of a truck’s hydraulic or fuel system, the banjo connector plays a role in maintaining the integrity of the fluid pathway, ensuring that pressure is maintained and leaks are minimized 2.

Purpose of the 3973033 Banjo Connector

The 3973033 Banjo Connector is specifically designed to serve as a reliable connection point in the hydraulic or fuel system of a truck. It facilitates the transfer of fluids under pressure, ensuring that the system operates smoothly. By providing a secure and sealed connection, it helps maintain system efficiency and prevents potential issues that could arise from leaks or loose connections 3.

Key Features

The 3973033 Banjo Connector features a robust design that includes high-quality materials to enhance its performance and durability. It is constructed from materials that can withstand the pressures and temperatures typical in truck hydraulic and fuel systems. Additionally, the connector includes precision-machined surfaces to ensure a tight seal, and it may incorporate features such as integrated gaskets to simplify installation and maintain seal integrity.

Benefits

Using the 3973033 Banjo Connector offers several benefits. It contributes to improved system efficiency by ensuring a secure connection that minimizes leaks. The design of the connector also enhances reliability, reducing the likelihood of connection failures. Furthermore, the connector is designed for ease of installation, which can save time during maintenance or repair procedures.

Installation Process

Installing the 3973033 Banjo Connector involves several steps to ensure a secure and effective fit. First, the mating surface should be cleaned to remove any debris or old gasket material. The connector is then positioned onto the surface, and the bolt is tightened to the manufacturer’s specified torque. It is important to use the correct tools and follow best practices to avoid over-tightening, which could damage the fitting, or under-tightening, which could lead to leaks.

Maintenance Tips

To ensure the long-term performance of the 3973033 Banjo Connector, regular maintenance is recommended. This includes inspecting the connector for signs of wear or damage, cleaning it as necessary, and replacing gaskets or the connector itself if any issues are detected. Adhering to recommended inspection intervals can help identify potential problems before they lead to system failures.

Troubleshooting Common Issues

Common issues with the 3973033 Banjo Connector may include leaks or connection failures. These can often be traced to improper installation, wear and tear, or damage to the gasket. Troubleshooting steps may involve re-tightening the connection, replacing the gasket, or, in some cases, replacing the connector. It is important to address these issues promptly to maintain system integrity.

Compatibility and Applications

The 3973033 Banjo Connector is designed for use in specific types of trucks and systems. It is commonly applied in environments where reliable fluid connections are critical. Understanding the compatibility of this connector with particular truck models or systems is important for ensuring optimal performance.

Safety Considerations

When working with the 3973033 Banjo Connector, it is important to follow safety guidelines and precautions. This includes handling fluids carefully to avoid spills or contact with skin, and ensuring that system pressure is within safe limits before making connections or disconnections. Proper personal protective equipment should be worn during installation and maintenance procedures.

Cummins Overview

Cummins Inc. is a leading manufacturer in the commercial truck industry, known for its commitment to quality and innovation in engine and component manufacturing. With a rich history of providing reliable and efficient solutions, Cummins continues to play a significant role in the development and maintenance of commercial vehicles, ensuring they meet the demands of modern transportation.

Cummins Engine Compatibility with Part 3973033

The Cummins part 3973033, a Banjo Connector, is designed to fit seamlessly with various Cummins engine models. This part is integral for ensuring proper fluid flow and pressure within the engine’s hydraulic and fuel systems.

B4.5 Engine Series

The B4.5 engine series is one of the models that utilize the Banjo Connector part 3973033. This engine is known for its reliability and efficiency, commonly used in various industrial and commercial applications. The Banjo Connector in this series is crucial for maintaining the integrity of the fuel and hydraulic lines, ensuring that there are no leaks or pressure drops that could affect engine performance.

Grouping of Compatible Engines

While the B4.5 engine is a notable example, the part 3973033 is also compatible with other Cummins engines that share similar design and operational requirements. These engines often require robust connections that can withstand high pressure and frequent use, making the Banjo Connector an essential component.

The compatibility of the Banjo Connector with these engines ensures that the fluid systems remain efficient and reliable, contributing to the overall performance and longevity of the engine.

Role of Part 3973033 Banjo Connector in Engine Systems

The 3973033 Banjo Connector is an essential component in the integration and operation of various engine systems, particularly those involving fluid transfer and high-pressure applications.

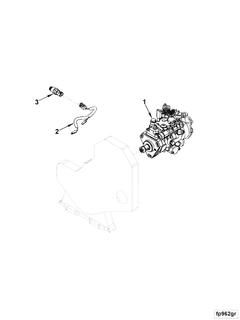

In the context of a Fuel Injection Pump, the Banjo Connector facilitates the secure connection between the pump and the fuel lines. This ensures a leak-free pathway for fuel to be delivered under high pressure to the injectors, which is vital for the precise atomization of fuel in the combustion chamber.

When integrated with a Fuel Pump, the Banjo Connector plays a similar role by providing a robust connection point between the pump and the fuel lines. This is important for maintaining the integrity of the fuel supply system, ensuring that fuel is delivered efficiently from the tank to the engine.

In broader applications involving general Pump systems, the Banjo Connector is used to connect the pump to various fluid lines. This is particularly important in systems where the fluid being pumped is under high pressure or is corrosive, as the Banjo Connector is designed to withstand such conditions while preventing leaks.

For Fuel systems in general, the Banjo Connector ensures that the fuel lines are securely attached to the various components within the system. This is important for maintaining the overall efficiency and reliability of the fuel delivery system, ensuring that fuel is delivered consistently and without interruption.

Conclusion

In summary, the 3973033 Banjo Connector is a key component in ensuring the secure and efficient transfer of fluids within engine systems. Its role in connecting various components such as fuel injection pumps, fuel pumps, and general pump systems underscores its importance in maintaining the overall performance and reliability of these systems.

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.