This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

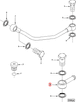

The 3944869 Banjo Connector, manufactured by Cummins, is a component used in commercial truck operations. Cummins is renowned for producing reliable and high-performance parts. This part is designed to facilitate the connection of hydraulic or fuel lines in trucks, ensuring efficient fluid transfer and system integrity.

Basic Concepts of Banjo Connectors

A banjo connector is a fitting used in fluid systems to join hoses or pipes. It typically consists of a short, tubular body with bolt holes at one end and a threaded fitting at the other. Within a truck’s hydraulic or fuel system, the banjo connector allows for the secure attachment of lines, enabling the transfer of fluids under pressure. Its design facilitates easy connection and disconnection, which is beneficial for maintenance and repair operations 1.

Purpose of the 3944869 Banjo Connector

This Cummins part is specifically engineered to play a role in the hydraulic or fuel systems of trucks. It provides a reliable connection point for lines, ensuring that fluids are transferred efficiently and without leaks. This connector is integral to maintaining the operational integrity of the system, contributing to the overall performance and reliability of the truck.

Key Features

The 3944869 boasts several key features that enhance its performance and durability. It is constructed from high-quality materials, ensuring resistance to wear and corrosion. The design includes precise threading and robust bolt holes, which contribute to a secure fit. Additionally, the connector may feature specialized seals or coatings that improve its sealing capabilities and protect against environmental factors.

Benefits

The advantages of using this part include improved sealing, which reduces the risk of leaks and ensures efficient fluid transfer. Its design allows for ease of installation, minimizing downtime during maintenance. Furthermore, the connector’s resistance to wear and corrosion extends its service life, providing long-term reliability in demanding commercial truck operations.

Installation Process

To install the 3944869, begin by ensuring that the connection points are clean and free of debris. Use the appropriate tools to attach the connector to the line, ensuring that it is securely fastened. It is important to follow the manufacturer’s guidelines for torque specifications to avoid over-tightening, which could damage the fitting. After installation, perform a pressure check to confirm that the connection is leak-free 2.

Maintenance Tips

To ensure the longevity and optimal performance of the 3944869, regular maintenance is recommended. This includes periodic inspection for signs of wear or corrosion, and cleaning the connector and surrounding areas to prevent the buildup of contaminants. If any issues are detected, prompt repair or replacement is advised to maintain system integrity.

Troubleshooting Common Issues

Common problems associated with banjo connectors, such as leaks or corrosion, can often be addressed through proper maintenance. If a leak is detected, inspect the connection for proper tightness and ensure that seals are intact. Corrosion may be mitigated by cleaning the connector and applying a protective coating. In cases where damage is severe, replacement of the connector may be necessary.

Safety Considerations

When working with the 3944869, it is important to follow safety practices to protect oneself and ensure system integrity. This includes wearing appropriate personal protective equipment, such as gloves and safety glasses. Additionally, always perform system pressure checks before and after installation to ensure that the connector is functioning correctly and that there are no leaks.

Cummins Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. With a history spanning over a century, Cummins has established a reputation for quality and innovation in the commercial truck industry. The company’s product range includes a variety of components and systems designed to enhance the performance, efficiency, and reliability of commercial vehicles.

Engine Compatibility of Part 3944869 (Banjo Connector) by Cummins

The 3944869, a Banjo Connector manufactured by Cummins, is designed to fit seamlessly within a range of engine models. This component is essential for maintaining fluid connections in various systems, ensuring the smooth operation of the engines.

Cummins 4B3.9 and 6B5.9 Engines

The 3944869 is compatible with the Cummins 4B3.9 and 6B5.9 engines. These engines are known for their robust performance and reliability, often used in heavy-duty applications. The banjo connector in these engines plays a role in securing fluid lines, ensuring there are no leaks and that the fluid flow is uninterrupted.

Cummins QSC8.3 CM554 and QSL9 CM554 Engines

Similarly, the 3944869 is also suitable for the Cummins QSC8.3 CM554 and QSL9 CM554 engines. These engines are part of Cummins’ advanced lineup, offering high efficiency and power. The banjo connector in these engines is critical for maintaining the integrity of hydraulic and fuel lines, contributing to the overall performance and longevity of the engine.

The compatibility of the 3944869 across these engines underscores its versatility and importance in ensuring the engines operate at peak efficiency.

Role of Part 3944869 Banjo Connector in Engine Systems

The 3944869 is an essential component in the fuel plumbing system of various engine setups. Its primary function is to facilitate the secure and efficient transfer of fuel between different parts of the engine system.

Fuel Plumbing Integration

In the fuel plumbing system, the Banjo Connector serves as a pivotal junction point. It connects the fuel lines to critical components such as fuel injectors, fuel rails, and the fuel pressure regulator. This ensures a consistent and reliable fuel supply to the engine, which is vital for optimal performance and efficiency. The Banjo Connector’s design allows for easy installation and removal, making it a convenient choice for both initial setup and maintenance procedures.

Location Specific Functions

The placement of the Banjo Connector varies depending on the engine configuration, but it is commonly found at key locations within the fuel system. For instance, it may be situated at the connection point between the fuel rail and the injectors. In this role, it ensures that fuel is distributed evenly across all cylinders, promoting balanced combustion and reducing the risk of misfires.

Another common location is at the connection to the fuel pressure regulator. Here, the Banjo Connector helps maintain the correct fuel pressure within the system, which is essential for the injectors to operate correctly. Proper fuel pressure ensures that the injectors deliver the right amount of fuel at the right time, contributing to efficient fuel consumption and reduced emissions.

Drain System Compatibility

In addition to its role in the fuel plumbing system, the Banjo Connector can also be integrated into the drain system of the engine. This is particularly relevant in systems where fuel lines need to be drained for maintenance or repair. The Banjo Connector’s design allows for quick and easy disconnection, facilitating the draining process without the need for complex tools or procedures. This feature is especially beneficial in scenarios where fuel lines need to be purged of contaminants or old fuel, ensuring that the engine operates with clean, fresh fuel.

Overall, the 3944869 plays a significant role in maintaining the integrity and efficiency of the engine’s fuel system. Its versatile application across different components underscores its importance in ensuring the engine functions smoothly and reliably.

Conclusion

The 3944869 Banjo Connector by Cummins is a critical component in the hydraulic and fuel systems of commercial trucks. Its design and features ensure efficient fluid transfer, system integrity, and long-term reliability. Proper installation, maintenance, and troubleshooting are essential to maximize its benefits and ensure the optimal performance of the truck’s engine systems.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.