This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

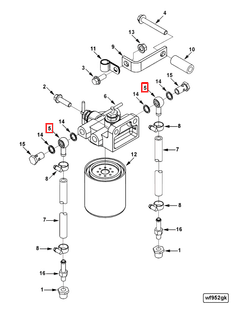

The Cummins 3864002 Banjo Connector is a specialized component designed for use in heavy-duty truck systems. Its purpose is to facilitate the connection of hoses or pipes within hydraulic or fuel systems, ensuring efficient fluid transfer and system operation. The significance of this connector lies in its ability to provide a secure and reliable connection, which is vital for the overall performance and safety of the truck 1.

Basic Concepts of Banjo Connectors

A banjo connector is a type of fitting used in fluid systems to join hoses or pipes. It typically consists of a short, cylindrical body with threaded ends and a bolt that secures the connection. In the context of a truck’s hydraulic or fuel system, the banjo connector plays a role by allowing for the transfer of fluids under pressure while maintaining a sealed connection. This ensures that the system operates efficiently and without leaks 2.

Purpose of the 3864002 Banjo Connector

The Cummins 3864002 Banjo Connector is specifically designed to connect hoses or pipes in the hydraulic or fuel systems of heavy-duty trucks. It facilitates the transfer of fluids, such as hydraulic fluid or fuel, ensuring that the system functions correctly. By providing a secure connection, it helps maintain system pressure and prevents leaks, which are critical for the efficient operation of the truck 3.

Key Features

The Cummins 3864002 Banjo Connector features a robust design that includes high-quality materials to enhance its performance and durability. It is constructed from materials that can withstand the pressures and temperatures encountered in heavy-duty truck systems. Additionally, the connector may include unique attributes such as corrosion-resistant coatings or specialized threading to ensure a tight and reliable seal 4.

Benefits

The Cummins 3864002 Banjo Connector offers several advantages. It contributes to improved system efficiency by ensuring a secure and leak-free connection. Its reliable design enhances the overall performance of the truck’s hydraulic or fuel system. Furthermore, the connector is designed for ease of installation or replacement, reducing downtime and maintenance costs.

Installation Process

Proper installation of the Cummins 3864002 Banjo Connector involves several steps. First, ensure that the hoses or pipes to be connected are clean and free of debris. Next, apply the appropriate sealant to the threads of the connector to ensure a tight seal. Then, thread the connector onto the hose or pipe and secure it with the provided bolt, tightening it to the manufacturer’s specified torque. Finally, inspect the connection for leaks and make any necessary adjustments.

Troubleshooting and Maintenance

Common issues with the Cummins 3864002 Banjo Connector may include leaks or loose connections. To diagnose problems, inspect the connector for signs of wear, corrosion, or damage. Ensure that the threads are clean and free of debris, and that the bolt is tightened to the correct torque. Regular maintenance, such as periodic inspection and re-tightening of the connector, can help ensure longevity and optimal performance.

Safety Considerations

When working with the Cummins 3864002 Banjo Connector, it is important to follow safety practices to prevent accidents or system failures. Always wear appropriate personal protective equipment, such as gloves and safety glasses. Ensure that the system is depressurized before attempting any maintenance or repairs. Follow the manufacturer’s instructions for installation and torque specifications to ensure a secure connection.

Cummins Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. With a history spanning over a century, Cummins has established a strong reputation in the automotive and heavy-duty truck industry for producing high-quality, reliable components. The company’s product range includes engines, powertrains, and aftermarket parts, all designed to meet the demanding requirements of heavy-duty applications.

Cummins Banjo Connector 3864002 Compatibility

The Cummins Banjo Connector part number 3864002 is a crucial component designed to fit seamlessly with several engine models. This part is integral to ensuring the proper functioning of the engine’s hydraulic or fuel systems by providing a secure connection between hoses and fittings.

Engine Compatibility

-

4B3.9 and 6B5.9 Engines

The 3864002 Banjo Connector is specifically engineered to fit the 4B3.9 and 6B5.9 engines. These engines, known for their reliability and performance, benefit from the precision and durability of this connector. It ensures that the hydraulic or fuel lines remain tightly sealed, preventing leaks and maintaining system integrity.

-

6C8.3 Engine

Similarly, the 6C8.3 engine is another model that is compatible with the 3864002 Banjo Connector. This engine, often used in heavy-duty applications, relies on the robust design of the connector to maintain optimal performance. The connector’s ability to withstand high pressure and temperature variations makes it an ideal choice for this engine.

Installation and Usage

When installing the 3864002 Banjo Connector, it is essential to follow the manufacturer’s guidelines to ensure a secure and leak-proof connection. Proper installation not only enhances the engine’s performance but also extends its lifespan by preventing potential damage caused by leaks.

The connector’s design allows for easy assembly and disassembly, making it a convenient choice for maintenance and repairs. Its compatibility with multiple engine models also simplifies inventory management for technicians and fleet operators.

Role of Part 3864002 Banjo Connector in Engine Systems

The Banjo Connector, identified as part 3864002, is integral to the efficient operation of various engine systems. It facilitates the secure connection between different components, ensuring the smooth transfer of fluids such as oil, fuel, or coolant.

Connection to the Fuel System

In the fuel system, the Banjo Connector is often used to link the fuel rail to the injectors. This connection ensures that fuel is delivered consistently and under the correct pressure to each injector, which is essential for optimal combustion and engine performance.

Integration with the Lubrication System

Within the lubrication system, the Banjo Connector plays a key role in connecting the oil gallery to the bearings and other lubricated components. It ensures that oil is distributed evenly, reducing friction and wear on moving parts. The secure fitting provided by the Banjo Connector prevents leaks, maintaining the integrity of the lubrication system.

Application in the Cooling System

In the cooling system, the Banjo Connector is employed to join hoses to the radiator or thermostat housing. This connection is vital for the circulation of coolant, which helps in regulating engine temperature and preventing overheating. The Banjo Connector’s design allows for easy maintenance and replacement, which is beneficial during routine servicing.

Use in Drain Systems

The Banjo Connector is also found in drain systems, where it connects to components such as the oil pan or fuel tank. It ensures that fluids can be efficiently drained during maintenance procedures, facilitating easier and cleaner operations.

Corrosion Resistance

One of the notable features of the Banjo Connector is its corrosion-resistant properties. This characteristic is particularly important in marine or off-road applications where the engine is exposed to harsh environments. The corrosion-resistant material ensures longevity and reliability of the connection, even in adverse conditions.

Strategic Location

The placement of the Banjo Connector is strategically chosen to provide easy access for maintenance while ensuring that it remains secure during engine operation. Its location is often near service points, allowing for quick disconnection and reconnection during fluid changes or system inspections.

Conclusion

In summary, the Cummins 3864002 Banjo Connector is a versatile component that enhances the functionality and maintenance of engine systems by providing secure, leak-proof connections across various critical points. Its robust design, compatibility with multiple engine models, and ease of installation make it an essential part for heavy-duty truck applications.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.