This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

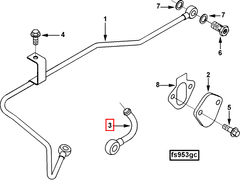

The Cummins 3863453 Banjo Connector is a specialized component designed for use in commercial trucks. It plays a role in the operation of these vehicles by facilitating the connection of hoses or pipes within hydraulic or fuel systems. Understanding its function and importance can contribute to the efficient maintenance and operation of commercial trucks.

Basic Concepts of Banjo Connectors

A banjo connector is a type of fitting used in fluid systems to join hoses or pipes. It typically consists of a short, tubular body with fittings on each end, one of which is usually a bolt or a nut. In the context of a truck’s hydraulic or fuel system, the banjo connector allows for the transfer of fluids under pressure, ensuring a secure and leak-free connection. Its design enables it to withstand high pressures and vibrations commonly encountered in truck operations 1.

Purpose of the 3863453 Banjo Connector

This Cummins part is specifically engineered to connect hoses or pipes in the hydraulic or fuel systems of trucks. It ensures a reliable seal, preventing leaks and maintaining system integrity. By providing a sturdy and secure connection point, it contributes to the overall efficiency and safety of the truck’s operation.

Key Features

This part is characterized by several key features that enhance its performance and durability. Its design includes precision-machined surfaces to ensure a tight seal, and it is constructed from high-quality materials resistant to corrosion and wear. Additionally, it may feature integrated gaskets or O-rings to further prevent leaks and ensure a secure connection.

Benefits

The use of the 3863453 Banjo Connector offers several benefits. It improves system efficiency by ensuring a secure and leak-free connection, which is vital for the proper operation of hydraulic and fuel systems. Its design also contributes to the reliability of these systems, reducing the likelihood of failures. Furthermore, the connector is designed for ease of installation and maintenance, allowing for quick replacement or repair when necessary.

Installation Process

Installing this part involves several steps to ensure a proper and secure fit. First, the connecting hoses or pipes should be prepared and cleaned. The connector is then positioned between the hoses or pipes, and the bolts or nuts are tightened to the specified torque using the appropriate tools. It is important to follow the manufacturer’s guidelines to ensure a correct installation.

Maintenance Tips

To ensure the longevity and optimal performance of the 3863453 Banjo Connector, regular maintenance is recommended. This includes inspecting the connector for signs of wear, corrosion, or leaks at regular intervals. Cleaning the connector and its surrounding areas can prevent the buildup of debris that may affect its performance. Additionally, checking the torque of the bolts or nuts can help maintain a secure connection.

Troubleshooting Common Issues

Common issues associated with banjo connectors include leaks and corrosion. If a leak is detected, it may be necessary to tighten the connection or replace the gasket or O-ring. Corrosion can be addressed by cleaning the affected areas and applying a corrosion-resistant coating. Regular inspections can help identify these issues early, allowing for timely repairs.

Safety Considerations

When working with the 3863453 Banjo Connector, it is important to follow safety guidelines to prevent accidents. This includes wearing appropriate personal protective equipment, ensuring the system is depressurized before beginning work, and using the correct tools and procedures for installation and maintenance. Adhering to these safety considerations can help protect both the technician and the equipment.

Cummins Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. With a history spanning over a century, Cummins has established a reputation for quality and innovation in the commercial truck industry. Its product range includes engines, powertrains, and related components, all designed to meet the demanding requirements of commercial applications.

Cummins Banjo Connector 3863453 in Engine Applications

The Cummins Banjo Connector 3863453 is a critical component in the engine systems of various Cummins engines, ensuring secure and leak-proof connections for hydraulic or fuel lines. This part is designed to withstand the rigors of engine operation, providing durability and reliability in demanding environments.

Application in 4B3.9 Engines

In the 4B3.9 engine, the Banjo Connector 3863453 is utilized to connect hydraulic lines that are essential for the operation of the engine’s fuel injection system. Its robust construction ensures that the connections remain tight and secure, preventing any potential leaks that could compromise engine performance.

Application in 6B5.9 Engines

Similarly, in the 6B5.9 engine, the Banjo Connector 3863453 plays a pivotal role in maintaining the integrity of the hydraulic and fuel lines. Given the higher power output and more complex system of the 6B5.9 engine, the reliability of this connector is even more crucial. It ensures that the lines can handle the increased pressure and stress without failure.

Grouping of Applications

Both the 4B3.9 and 6B5.9 engines benefit from the use of the Banjo Connector 3863453 due to its universal design and compatibility with Cummins engines. This part is engineered to fit seamlessly into the engine’s hydraulic and fuel systems, providing a reliable connection that is essential for the smooth operation of the engine.

Role of Part 3863453 Banjo Connector in Engine Systems

The Banjo Connector, identified as part 3863453, is integral to the efficient operation of various engine systems, particularly in the context of fuel management and transfer.

In systems involving a Lift Pump, the Banjo Connector facilitates the secure and reliable connection between the pump and the fuel lines. This ensures that fuel is efficiently drawn from the tank and pressurized to the required levels before it reaches the main engine fuel system. The connector’s design allows for easy maintenance and replacement, minimizing downtime during servicing.

When integrated with a general Pump system, the Banjo Connector plays a similar role. It ensures a leak-free connection that maintains the integrity of the fuel supply under varying pressure conditions. This is essential for consistent engine performance and reliability.

In Fuel Transfer applications, the Banjo Connector is used to link different sections of the fuel line, enabling the smooth transfer of fuel between components. This is particularly important in systems where fuel is transferred between tanks or from a tank to the engine. The connector’s robust construction ensures that it can withstand the pressures and vibrations associated with fuel transfer, contributing to the overall efficiency and safety of the fuel system 2.

Conclusion

The Cummins 3863453 Banjo Connector is a vital component in the hydraulic and fuel systems of commercial trucks and engines. Its design ensures secure, leak-free connections that are essential for the efficient and reliable operation of these systems. Regular maintenance and adherence to safety guidelines are crucial for maximizing the performance and longevity of this part.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.