This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

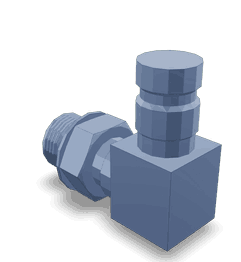

The 3819616 Coupling Nipple, manufactured by Cummins, is a critical component in commercial trucks, integral to the fluid systems. It facilitates secure and leak-free transfer of fluids between system components, enhancing the truck’s operational efficiency and reliability 1.

Basic Concepts of a Coupling Nipple

A coupling nipple is a short pipe fitting designed to connect two sections of pipe or fluid-carrying components securely and leak-proof. It is used in various systems, including hydraulic, pneumatic, and fuel systems 2.

Purpose of the 3819616 Coupling Nipple in Truck Operation

This Cummins part ensures efficient and leak-free transfer of fluids such as fuel, hydraulic fluid, or coolant within the truck’s systems. Secure connections are essential for the proper functioning of these systems, preventing inefficiencies or failures 3.

Key Features of the 3819616 Coupling Nipple

The 3819616 is made from high-quality, corrosion-resistant materials, ensuring durability. Its thread type is designed for a secure fit, and unique design elements facilitate easy installation and compatibility with other system components 4.

Benefits of Using the 3819616 Coupling Nipple

Using this part offers improved reliability in fluid connections, ease of installation, and seamless integration with other components, ensuring the truck’s systems operate efficiently 5.

Installation Process

Installing the 3819616 requires a wrench and sealant. Best practices include cleaning connection points, applying sealant, and tightening to the manufacturer’s specified torque for a secure, leak-free connection 6.

Troubleshooting Common Issues

Common issues with coupling nipples include leaks or loose connections. Regular inspection for wear or damage, tightening or replacing the nipple if necessary, and using the correct sealant during installation can prevent leaks 7.

Maintenance Tips

Regular maintenance of the 3819616 involves inspecting for wear or corrosion, cleaning the nipple and connections to prevent buildup, and following recommended intervals for checks to ensure long-term performance and prevent failures 8.

Cummins: A Brief Overview

Cummins Inc. is renowned for its high-quality truck components, with a history of innovation and commitment to quality. The company’s product range includes engines, powertrains, and critical components for commercial vehicles 9.

Coupling Nipple 3819616 Compatibility with Cummins Engines

The 3819616 is designed for seamless integration with various Cummins engine models, ensuring efficient and reliable performance of the engine’s fuel and lubrication systems 10.

ISM Series Engines

- ISM CM570

- ISM CM570/870

- ISM CM876

- ISM11 CM876 SN

L10 Series Engines

- L10 CELECT

- L10 GAS

M11 Series Engines

- M11 CELECT

- M11 CELECT PLUS

- M11 MECHANICAL

N14 Series Engine

- N14 MECHANICAL

NH/NT 855

QSM11 CM570

Role of Part 3819616 Coupling Nipple in Engine Systems

The 3819616 is vital in various engine systems, ensuring secure connections between components and smooth engine operation.

Engine Oil System

In the engine oil system, the Coupling Nipple connects the oil filter cooler to the lubricating oil filter head, ensuring efficient oil circulation after cooling.

Lubricating Oil System

Within the lubricating oil system, it links the lubricating oil pump to the lubricating oil filter top-level assembly head, ensuring a consistent flow of pressurized oil to reduce friction and wear.

Fuel System

In the fuel system, the Coupling Nipple connects the fuel pump inlet to the fuel pump, maintaining the integrity of the fuel line and ensuring correct fuel pressure delivery to the engine’s combustion chambers.

Cooling System

For the cooling system, it joins the oil cooler water pump to the plumbing, ensuring effective cooling water circulation through the oil cooler to maintain optimal oil temperature and enhance engine performance.

Service and Conversion Kits

In service kits and conversion kits, such as the lubricating pump conversion kit, the Coupling Nipple connects various components, facilitating easier maintenance and upgrades without leaks or inefficiencies.

General Plumbing and Fittings

Across all systems, the Coupling Nipple serves as a versatile fitting, connecting base parts and various plumbing components, ensuring secure and leak-free connections fundamental to the reliability and efficiency of the engine systems.

Conclusion

The 3819616 Coupling Nipple is a vital component in commercial trucks, ensuring secure and efficient fluid transfer within the engine systems. Its compatibility with various Cummins engine models, coupled with its key features and benefits, underscores its importance in maintaining the reliability and performance of commercial vehicles.

-

Hilgers, Michael. The Diesel Engine Second Edition. Springer Nature, 2023.

↩ -

Robert Bosch GmbH. Bosch Automotive Handbook 9th Edition. Robert Bosch GmbH, 2014.

↩ -

Dempsey, Paul. Troubleshooting and Repairing Diesel Engines, 5th Edition. McGraw-Hill, 2018.

↩ -

Parikyan, Tigran Ed. Advances in Engine and Powertrain Research and Technology. Springer Nature, 2022.

↩ -

Cummins Inc. Engine B6.7 CM2350 B148B and B6.7 CM2450 B217B Stop-Start Applications, Service Manual (5411262).

↩ -

Cummins Inc. Engine B6.7 CM2350 B148B and B6.7 CM2450 B217B Stop-Start Applications, Service Manual (5411262).

↩ -

Dempsey, Paul. Troubleshooting and Repairing Diesel Engines, 5th Edition. McGraw-Hill, 2018.

↩ -

Cummins Inc. Engine B6.7 CM2350 B148B and B6.7 CM2450 B217B Stop-Start Applications, Service Manual (5411262).

↩ -

Cummins Inc. Corporate Website. Accessed March 2024.

↩ -

Cummins Inc. Engine B6.7 CM2350 B148B and B6.7 CM2450 B217B Stop-Start Applications, Service Manual (5411262).

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.