This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

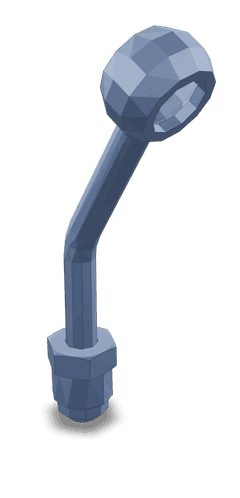

The Cummins 3815420 Banjo Connector is a specialized component designed for use in commercial trucks. Its purpose is to facilitate the connection of hoses or pipes within hydraulic or fuel systems. This connector plays a role in ensuring the efficient and reliable operation of these systems, contributing to the overall performance and safety of the vehicle 1.

Basic Concepts of Banjo Connectors

A banjo connector is a type of fitting used in fluid systems to join hoses or pipes. It typically consists of a bolt, a banjo fitting, and a pair of washers. The banjo fitting has a curved shape, resembling a banjo, which allows for a secure connection when tightened. In the context of a truck’s hydraulic or fuel system, the banjo connector ensures a leak-free and robust connection, enabling the smooth transfer of fluids under pressure 2.

Purpose of the 3815420 Banjo Connector

The 3815420 Banjo Connector is specifically designed to connect hoses or pipes in the hydraulic or fuel systems of commercial trucks. It ensures a secure and reliable connection, which is vital for the proper functioning of these systems. By providing a stable link between components, the connector helps maintain system integrity and efficiency 3.

Key Features

The 3815420 Banjo Connector features a robust design that includes high-quality materials such as steel and durable washers. Its curved banjo fitting allows for a tight seal when connected, enhancing performance and durability. The connector is engineered to withstand high-pressure conditions, ensuring long-lasting reliability in demanding environments.

Benefits

The 3815420 Banjo Connector offers several benefits, including improved system efficiency through secure connections that minimize leaks. Its design reduces the risk of fluid loss, which can lead to system failures. Additionally, the connector’s durability under high-pressure conditions ensures consistent performance, contributing to the overall reliability of the truck’s hydraulic or fuel system.

Installation Process

Installing the 3815420 Banjo Connector requires careful attention to detail to ensure a secure and effective connection. The process involves selecting the appropriate hoses or pipes, applying the necessary washers, and tightening the banjo fitting with the provided bolt. Using the correct tools and following best practices, such as torque specifications, is crucial to achieving a leak-free connection.

Troubleshooting Common Issues

Common issues with banjo connectors include leaks and improper connections. To address these problems, it is important to inspect the fittings for damage, ensure the correct washers are used, and verify that the connection is tightened to the proper specifications. Regular maintenance and inspections can help identify and resolve these issues promptly.

Maintenance Tips

Regular maintenance of the 3815420 Banjo Connector is essential for ensuring long-term performance and reliability. This includes periodic inspections for signs of wear or damage, cleaning the fittings to remove any debris, and replacing washers as needed. Adhering to recommended inspection intervals and maintenance procedures will help maintain the integrity of the connection.

Compatibility and Applications

The 3815420 Banjo Connector is versatile and widely used in various truck models and systems. Its design allows for compatibility with different hydraulic and fuel system configurations, making it a valuable component in the commercial truck industry. The connector’s widespread use underscores its reliability and effectiveness in diverse applications.

Cummins Overview

Cummins Inc. is a leading manufacturer in the commercial truck industry, known for its high-quality products and innovative solutions. With a rich history of providing reliable and efficient components, Cummins has established a strong reputation for excellence. The 3815420 Banjo Connector is a testament to Cummins’ commitment to quality and performance in the automotive sector.

Cummins Banjo Connector 3815420 in Engine Applications

The Cummins Banjo Connector part number 3815420 is a component in various engine systems, ensuring secure and leak-free connections for hydraulic or fuel lines. This part is designed to withstand high pressures and temperatures, making it suitable for demanding engine environments.

Engine Compatibility

The 3815420 Banjo Connector is compatible with several Cummins engine models, including but not limited to:

- 6C8.3: This engine model benefits from the robust design of the 3815420 Banjo Connector, which provides a reliable connection for hydraulic lines, ensuring optimal performance and longevity.

Application in Engine Systems

In the 6C8.3 engine, the 3815420 Banjo Connector is typically used in the following systems:

- Fuel Delivery Systems: Ensuring that fuel lines are securely attached and free from leaks.

- Hydraulic Systems: Providing a dependable connection for hydraulic lines, which is crucial for the engine’s operation.

The design of the 3815420 Banjo Connector allows it to be easily installed and removed, facilitating maintenance and repairs. Its durability and resistance to wear make it a preferred choice for use in heavy-duty engines like the 6C8.3.

Role of Part 3815420 Banjo Connector in Engine Systems

The Part 3815420 Banjo Connector is a component in various engine systems, particularly within the fuel system. It facilitates the secure connection between different parts of the fuel system, ensuring efficient and reliable fuel delivery to the engine.

Fuel System Integration

In the fuel system, the Banjo Connector is utilized to join fuel lines to the fuel filter and other critical components. This connection is vital for maintaining the integrity of the fuel flow, preventing leaks, and ensuring that the fuel system operates under the correct pressure. The Banjo Connector is often found at the points where fuel lines connect to the fuel filter, fuel filter mounting brackets, and other fuel system accessories.

Fuel Filter and Mounting Systems

When integrating with the fuel filter and its mounting system, the Banjo Connector plays a role in securing the fuel lines to the filter housing. This ensures that the fuel passes through the filter without any interruptions, which is essential for removing impurities and maintaining the quality of the fuel delivered to the engine. The secure connection provided by the Banjo Connector is also important for the fuel filter mounting system, as it helps to stabilize the filter within the engine compartment.

Plumbing and Accessories

Within the broader context of engine plumbing and fuel system accessories, the Banjo Connector is used to create reliable connections between various components. This includes linking fuel lines to sensors, pressure regulators, and other accessories that monitor and control the fuel system’s performance. The Banjo Connector’s design allows for easy installation and removal, which is beneficial during maintenance or upgrades to the fuel system.

Overall System Efficiency

By ensuring secure and leak-free connections throughout the fuel system, the Banjo Connector contributes to the overall efficiency and reliability of the engine. It helps maintain consistent fuel pressure and flow, which are essential for optimal engine performance and fuel economy. Additionally, the use of the Banjo Connector in fuel system accessories and plumbing enhances the system’s durability and reduces the risk of fuel leaks, which can be hazardous and lead to engine damage.

Conclusion

The Cummins 3815420 Banjo Connector is a vital component in the hydraulic and fuel systems of commercial trucks. Its robust design, compatibility with various engine models, and role in ensuring secure and leak-free connections contribute to the overall performance and reliability of these systems. Regular maintenance and proper installation are key to maximizing the benefits of this Cummins part.

-

Goodnight, Nicholas, and Kirk VanGelder. Automotive Braking Systems CDX Master Automotive Technician Series. Jones Bartlett Learning, 2019.

↩ -

Pacejka, Hans B. Tyre and Vehicle Dynamics. Butterworth-Heinemann, 2006.

↩ -

Bennett, Sean, and Ian Andrew Norman. Heavy Duty Truck Systems Fifth Edition. Delmar Cengage Learning, 2011.

↩

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.