This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

The 3638769 Coupling Nipple, manufactured by Cummins, is a component that plays a role in the fluid systems of commercial trucks. Cummins, a well-established name in the commercial truck industry, produces this part to enhance the efficiency and reliability of truck operations. Understanding the function and significance of the 3638769 Coupling Nipple is important for maintaining and optimizing the performance of heavy-duty trucks.

Basic Concepts of Coupling Nipples

A coupling nipple is a short pipe fitting used to connect two sections of pipe or other fluid system components. Its general function is to provide a secure and leak-proof connection, allowing for the transfer of fluids such as fuel, oil, or coolant. In the context of heavy-duty trucks, coupling nipples are integral to ensuring that fluid systems operate smoothly and efficiently 1.

Purpose of the 3638769 Coupling Nipple

The 3638769 Coupling Nipple is designed to connect different components within a truck’s fluid system. It facilitates the transfer of fluids between various parts, ensuring that systems such as the fuel delivery, lubrication, and cooling systems function correctly. By providing a reliable connection point, this coupling nipple contributes to the overall performance and durability of the truck 2.

Key Features

The 3638769 Coupling Nipple features a robust material composition, typically made from high-quality metal alloys to withstand the pressures and temperatures encountered in truck fluid systems. Its design includes precision-machined threads and a secure locking mechanism to prevent leaks and ensure a tight fit. Additionally, the coupling nipple may have corrosion-resistant coatings to enhance its longevity in harsh operating environments 3.

Benefits

The advantages of using the 3638769 Coupling Nipple include improved efficiency in fluid transfer, enhanced durability under demanding conditions, and increased reliability in truck operations. Its robust construction and precise engineering contribute to reduced maintenance needs and longer service life, making it a valuable component for commercial truck fleets.

Installation Process

Proper installation of the 3638769 Coupling Nipple involves several steps. First, ensure that the connecting pipes or components are clean and free of debris. Apply a compatible thread sealant to the threads of the coupling nipple to enhance the seal. Carefully screw the nipple into the corresponding fitting, using a wrench to tighten it securely without over-torquing. Finally, check for any leaks by pressurizing the system and inspecting the connection points.

Common Issues and Troubleshooting

Typical problems with the 3638769 Coupling Nipple may include leaks, corrosion, or thread damage. To address these issues, first, inspect the connection for any signs of wear or damage. If a leak is detected, ensure that the threads are clean and re-apply thread sealant if necessary. In cases of corrosion, consider replacing the coupling nipple to prevent further degradation. For thread damage, it may be necessary to use a thread repair kit or replace the fitting entirely.

Maintenance Tips

Regular maintenance practices for the 3638769 Coupling Nipple include periodic inspection for signs of wear, corrosion, or leaks. Cleaning the fitting and surrounding areas can prevent debris from interfering with the connection. Additionally, reapplying thread sealant during routine maintenance can help maintain a secure seal. Following these practices can ensure the longevity and optimal performance of the coupling nipple.

Safety Considerations

When working with the 3638769 Coupling Nipple, it is important to observe safety guidelines to prevent accidents or injuries. Ensure that the truck’s engine is off and the fluid system is depressurized before beginning any work. Use appropriate personal protective equipment, such as gloves and safety glasses, to protect against fluid spills or debris. Additionally, follow proper torque specifications when tightening the coupling nipple to avoid over-tightening, which can lead to thread damage.

Cummins Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. With a history spanning over a century, Cummins has established a strong reputation in the commercial truck industry for producing high-quality, reliable components. Their product range includes engines, powertrains, and aftermarket parts, all designed to meet the demanding needs of commercial truck operators.

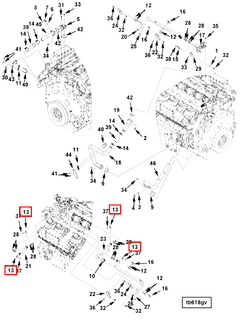

Coupling Nipple (Part 3638769) Compatibility with Cummins Engines

The Coupling Nipple, part number 3638769, manufactured by Cummins, is a critical component in the engine systems of various Cummins engine models. This part is designed to ensure a secure and efficient connection between different parts of the engine, facilitating the transfer of power and fluids.

QSK60 Series

The QSK60 series engines, including the QSK60 CM500 and QSK60 CM850 MCRS, are high-performance engines widely used in various industrial applications. The Coupling Nipple (3638769) is integral to these engines, providing a reliable connection that is essential for the smooth operation of the engine’s hydraulic and fuel systems.

- QSK60 CM500: This engine model benefits from the precise engineering of the Coupling Nipple, ensuring that the hydraulic and fuel lines are securely fastened, reducing the risk of leaks and maintaining optimal engine performance.

- QSK60 CM850 MCRS: In this model, the Coupling Nipple plays a crucial role in maintaining the integrity of the engine’s high-pressure systems. Its robust design ensures that the connections remain tight under the demanding conditions of heavy-duty operations.

QSK60G

The QSK60G engine is another variant in the QSK60 series, known for its durability and efficiency. The Coupling Nipple (3638769) is a key component in this engine, providing a dependable connection that supports the engine’s operational demands.

- QSK60G: This engine model relies on the Coupling Nipple to maintain the integrity of its hydraulic and fuel systems. The part’s design ensures that the connections are secure, which is vital for the engine’s performance and longevity.

In summary, the Coupling Nipple (3638769) is a vital component in the QSK60 series engines, ensuring that the connections within the engine’s systems are secure and reliable. Its importance cannot be overstated, as it directly impacts the engine’s performance and durability.

Conclusion

The 3638769 Coupling Nipple is a fundamental component in maintaining the integrity and efficiency of various engine systems. It ensures that air flows seamlessly through the engine’s intricate network of components, facilitating the connection between the aftercooler and the subsequent air intake components. Its robust design and precise engineering make it a valuable asset for commercial truck fleets, contributing to reduced maintenance needs and longer service life.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.