3638767

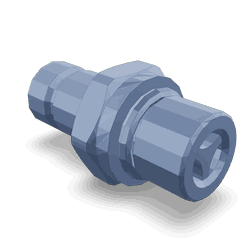

Coupling Nipple

Cummins®

AVAILABLE

More than 10 are currently available

Ships within 2-4 business days

This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

The 3638767 Coupling Nipple by Cummins is a component designed for use in heavy-duty truck systems. Its purpose is to facilitate the connection between different parts of a fluid system, ensuring the smooth transfer of fluids such as fuel or hydraulic fluid. The significance of this part lies in its role in maintaining the integrity and efficiency of the truck’s fluid systems.

Basic Concepts of Coupling Nipples

A coupling nipple is a short pipe fitting used to connect two sections of pipe or other fluid conduits. Its general function in fluid systems is to provide a secure and leak-proof connection, allowing for the efficient transfer of fluids under pressure. Within the broader context of a truck’s hydraulic or fuel system, coupling nipples play a vital role in ensuring that fluids are delivered to their intended destinations without loss or contamination 1.

Purpose of the 3638767 Coupling Nipple

The 3638767 Coupling Nipple is specifically designed to serve as an intermediary connection point within a truck’s fluid system. It ensures that the connection between components is both secure and reliable, contributing to the overall efficiency and reliability of the system it is a part of. This component is integral to maintaining the proper flow of fluids, which is crucial for the operation of various truck systems 2.

Key Features

The 3638767 Coupling Nipple boasts several key features that enhance its performance and durability. It is constructed from high-quality materials that are resistant to corrosion and wear, ensuring a long service life. The design of the nipple includes precise threading and sealing surfaces that facilitate a secure connection. Additionally, it may feature unique characteristics such as anti-leak mechanisms or easy-to-use coupling designs that simplify installation and maintenance 3.

Benefits

The advantages provided by the 3638767 Coupling Nipple include improved system efficiency and reliability. By ensuring a secure and leak-proof connection, it helps to maintain the integrity of the fluid system, reducing the risk of fluid loss or contamination. This can lead to cost savings for fleet operators by minimizing the need for repairs and reducing downtime. Furthermore, the durability of the coupling nipple contributes to the overall longevity of the truck’s fluid system.

Installation Process

Proper installation of the 3638767 Coupling Nipple involves several steps to ensure correct fitting and function. Begin by identifying the correct location for the nipple within the fluid system. Use the appropriate tools to clean the connection points, ensuring they are free from debris and contaminants. Apply any necessary sealants or lubricants as per the manufacturer’s instructions. Carefully thread the nipple into place, ensuring it is securely fastened without over-tightening, which could damage the threads. Finally, perform a pressure test to confirm the connection is leak-proof.

Maintenance Tips

Regular maintenance of the 3638767 Coupling Nipple is crucial for ensuring longevity and optimal performance. Inspect the nipple at regular intervals for signs of wear, corrosion, or leaks. Clean the coupling surfaces as needed to remove any buildup that could impede a secure connection. Replace any damaged or worn components promptly to prevent system failures. Following these maintenance practices will help to ensure the coupling nipple continues to function effectively throughout its service life.

Troubleshooting Common Issues

Common problems associated with coupling nipples, such as leaks or blockages, can often be identified through regular inspection and maintenance. If a leak is detected, check the connection for proper tightness and ensure that all sealing surfaces are clean and undamaged. Blockages may require disassembling the connection to clear any debris or buildup. Addressing these issues promptly can help to maintain the efficiency and reliability of the truck’s fluid system.

Safety Considerations

When working with the 3638767 Coupling Nipple, it is important to observe several safety guidelines and precautions. Ensure that the system is depressurized before beginning any work to prevent injury from pressurized fluid. Use the appropriate personal protective equipment, such as gloves and safety glasses, to protect against potential hazards. Follow all manufacturer instructions for handling, installation, and maintenance to ensure safe and effective use of the component.

Cummins Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes a wide range of power solutions, including engines, filtration, and emissions solutions. With a history spanning over a century, Cummins has established itself as a trusted name in the automotive and heavy-duty truck industry. The company is known for its commitment to quality and innovation, providing reliable and efficient power solutions to meet the demands of various industries.

Cummins Engine Part 3638767: Coupling Nipple Compatibility

The Cummins part 3638767, a Coupling Nipple, is a critical component that ensures the proper connection and operation of various engine systems. This part is designed to fit seamlessly within a range of Cummins engines, providing a reliable interface for fluid or gas transfer between different parts of the engine. Below is a detailed overview of its compatibility with specific engine models:

QSK19 and QSK95 Series

The Coupling Nipple part 3638767 is compatible with the QSK19 CM2350 K114, QSK95 CM2350 K111, and QSK95 CM2350 K113 engines. These engines are part of the QSK series, which are known for their robust design and high performance. The part ensures that the coupling between the engine’s components is secure and efficient, contributing to the overall reliability and longevity of the engine.

QSK45, QSK60, and QSK78 Series

The part 3638767 also fits the QSK45 CM500, QSK60 CM500, QSK60 CM850 MCRS, and QSK78 CM500 engines. These engines are part of the QSK series, which are designed for a variety of applications, from industrial to marine. The Coupling Nipple ensures that the connection between different parts of the engine is tight and leak-proof, which is crucial for maintaining engine efficiency and performance.

QSK60G Series

The QSK60G engine is another model that is compatible with the part 3638767. This engine is known for its versatility and is often used in heavy-duty applications. The Coupling Nipple ensures that the engine’s components are properly aligned and connected, which is essential for the smooth operation of the engine.

QST30 Series

The QST30 CM2350 T101 engine is also compatible with the part 3638767. This engine is part of the QST series, which is designed for specific applications that require high power and efficiency. The Coupling Nipple ensures that the engine’s components are securely connected, which is crucial for maintaining the engine’s performance and reliability.

QSK60 G CM2358 K110

The QSK60 G CM2358 K110 engine is another model that is compatible with the part 3638767. This engine is part of the QSK series and is known for its high performance and reliability. The Coupling Nipple ensures that the engine’s components are properly connected, which is essential for maintaining the engine’s efficiency and performance.

Role of Part 3638767 Coupling Nipple in Engine Systems

The Part 3638767 Coupling Nipple is an essential component that facilitates the connection and interaction between various engine systems. Its role is pivotal in ensuring seamless operation and efficiency across multiple subsystems. Here’s how it integrates with the provided components:

Fuel System

In the fuel system, the Coupling Nipple is utilized to connect the fuel filter to the fuel filter head. This connection ensures a secure and leak-free passage of fuel from the filter to the engine, maintaining consistent fuel pressure and quality.

Lubrication System

Within the lubrication system, the Coupling Nipple plays a significant role in connecting the lubricating oil filter to the lubricating oil filter head. This ensures that clean oil is efficiently circulated throughout the engine, reducing wear and tear on moving parts.

Aftercooler System

In the aftercooler system, the Coupling Nipple is employed to link the aftercooler to the plumbing arrangement. This connection is vital for maintaining the optimal temperature of the air entering the engine, enhancing overall performance and efficiency.

Crankcase Breather System

The Coupling Nipple is also integral in the crankcase breather system, where it connects the crankcase breather to the CRC breather arrangement. This helps in venting gases from the crankcase, preventing pressure build-up and ensuring smooth engine operation.

Engine Lubrication Primer

In the engine lubrication primer system, the Coupling Nipple is used to connect the primer to the lubrication system. This ensures that the engine is adequately primed with oil before start-up, facilitating easier starting and protecting engine components during initial operation.

Cylinder Block and Related Components

The Coupling Nipple is utilized in the cylinder block system to connect various components such as the cylinder, crankshaft and bearings, and cylinder block hardware kit. These connections are essential for maintaining the integrity of the engine’s structural and functional components.

Flywheel and Housing

In the flywheel system, the Coupling Nipple connects the flywheel to the flywheel housing. This ensures that the flywheel operates smoothly, contributing to the engine’s balance and efficiency.

Service Kit Integration

When incorporated into a service kit, the Coupling Nipple aids in the replacement and maintenance of various engine components, ensuring that all connections are secure and function as intended.

Accessories and Filters

The Coupling Nipple is also used in connecting various accessories and filters within the engine system, ensuring that all components work in harmony to deliver optimal engine performance.

Conclusion

The 3638767 Coupling Nipple by Cummins is a critical component in the maintenance and operation of heavy-duty truck fluid systems. Its role in ensuring secure, leak-proof connections across various engine subsystems highlights its importance in maintaining system efficiency and reliability. Proper installation, regular maintenance, and prompt troubleshooting of common issues are essential practices to maximize the performance and longevity of this component. By understanding the key features, benefits, and compatibility of the 3638767 Coupling Nipple, fleet operators and technicians can ensure the optimal functioning of their vehicles, leading to cost savings and reduced downtime.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.