3635519

Flexible Coupling

Cummins®

AVAILABLE

More than 10 are currently available

Ships within 2-4 business days

This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

The Cummins 3635519 Flexible Coupling is a component designed for use in heavy-duty truck operations. It serves as a connector between two shafts, allowing for the transmission of torque while accommodating minor misalignments and absorbing shock loads. This coupling is integral to the smooth and efficient operation of the truck’s drivetrain and other mechanical systems.

Basic Concepts of Flexible Couplings

Flexible couplings are mechanical devices used to connect two shafts in a system, enabling the transfer of torque and rotation. They are designed to accommodate misalignments between the shafts, which can occur due to thermal expansion, manufacturing tolerances, or operational stresses. Flexible couplings also help in reducing vibration and shock loads, thereby protecting other components in the system from undue stress and wear. They find applications in various mechanical systems, including pumps, compressors, and drivetrains 1.

Purpose of the Cummins 3635519 Flexible Coupling

The Cummins 3635519 Flexible Coupling plays a specific role in the operation of a truck by connecting the engine to the transmission or other components within the drivetrain. It allows for the efficient transfer of power while accommodating angular, parallel, and axial misalignments. This flexibility helps in maintaining the alignment of the shafts under varying operational conditions, which is crucial for the longevity and performance of the drivetrain components.

Key Features

The Cummins 3635519 Flexible Coupling is characterized by several key features that enhance its performance. It is constructed from high-quality materials that provide durability and resistance to wear. The design includes elements such as elastomeric inserts or metallic components that allow for flexibility and shock absorption. Additionally, the coupling may feature unique attributes like self-aligning capabilities or corrosion-resistant coatings, which contribute to its reliability and efficiency in heavy-duty applications.

Benefits of Using the 3635519 Flexible Coupling

Utilizing the Cummins 3635519 Flexible Coupling offers several advantages. Its robust construction and design contribute to improved durability, reducing the frequency of replacements and repairs. The coupling’s ability to accommodate misalignments and absorb shock loads leads to reduced maintenance needs and extends the lifespan of connected components. Furthermore, by ensuring smooth power transmission and minimizing vibrations, the coupling enhances the overall operational efficiency of the truck.

Installation Considerations

When installing the Cummins 3635519 Flexible Coupling, it is important to follow guidelines and best practices to ensure proper functionality. Preparatory steps may include cleaning the shaft surfaces and inspecting them for damage. The use of appropriate tools and alignment equipment is recommended to achieve accurate shaft alignment. Careful attention to torque specifications during installation helps in securing the coupling without overtightening, which could lead to premature wear.

Troubleshooting Common Issues

Flexible couplings, including the Cummins 3635519, may encounter issues such as excessive wear, misalignment, or failure of elastomeric components. Diagnosing these problems involves inspecting the coupling for signs of damage, checking alignment, and assessing the condition of the elastomeric elements. Recommended solutions may include realigning the shafts, replacing worn components, or addressing any underlying causes of misalignment or vibration.

Maintenance Tips

To ensure the longevity and optimal performance of the Cummins 3635519 Flexible Coupling, routine maintenance practices are advisable. This includes regular inspection for signs of wear or damage, checking alignment, and ensuring that all fasteners are secure. Cleaning the coupling and its surroundings to remove dirt and debris can also prevent contamination that may lead to premature wear. Adhering to manufacturer-recommended inspection schedules and care instructions will help in maintaining the coupling’s efficiency and reliability.

Cummins Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. With a history spanning over a century, Cummins has established a reputation for quality and innovation in the automotive industry, particularly in the realm of heavy-duty truck components. The company’s extensive product range and commitment to customer satisfaction have made it a trusted name among fleet operators and maintenance professionals.

Cummins Flexible Coupling 3635519 Compatibility with Various Engine Models

The Cummins Flexible Coupling 3635519 is designed to seamlessly integrate with a range of Cummins engine models, ensuring optimal performance and reliability across different applications. This coupling is engineered to accommodate the unique characteristics of each engine model, providing a robust connection that can withstand the rigors of various operational environments.

K50 and QSK50 Series

The K50 and QSK50 series engines benefit from the flexibility and durability of the 3635519 coupling. These engines, known for their power and efficiency, require a coupling that can handle significant torque and rotational forces. The 3635519 coupling is specifically designed to fit these models, ensuring a secure and stable connection that minimizes vibration and extends the lifespan of the engine components.

QSK19 and QSK60 Series

For the QSK19 and QSK60 series engines, the 3635519 coupling offers a perfect match in terms of both design and functionality. These engines are often used in heavy-duty applications, where reliability and performance are critical. The coupling’s ability to absorb misalignment and dampen vibrations makes it an ideal choice for these models, enhancing overall engine efficiency and reducing maintenance needs.

CM850 and CM2150 Series

The CM850 and CM2150 series engines also find a reliable partner in the 3635519 coupling. These engines are commonly used in a variety of industrial and commercial applications, where consistent performance is essential. The coupling’s design ensures that it can handle the specific torque and rotational demands of these engines, providing a stable and durable connection that supports long-term operation.

MCRS and K107/K108 Models

The MCRS and K107/K108 models are part of the broader Cummins engine lineup, each with its own set of operational requirements. The 3635519 coupling is engineered to fit these models, offering a solution that addresses the unique challenges posed by their design and application. Whether used in marine, power generation, or industrial settings, this coupling ensures that the engines can operate at peak efficiency with minimal downtime.

By providing a comprehensive fit for these diverse engine models, the Cummins Flexible Coupling 3635519 demonstrates its versatility and reliability, making it a valuable component for maintaining the performance and longevity of Cummins engines across various industries.

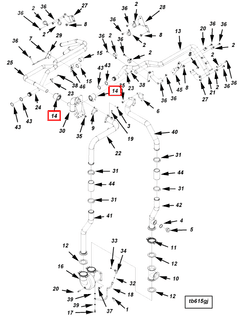

Role of Part 3635519 Flexible Coupling in Engine Systems

The part 3635519 Flexible Coupling is integral to the seamless operation of various engine components. It facilitates the connection between the camshaft and gear, allowing for efficient power transmission while accommodating minor misalignments and absorbing vibrations, which enhances the durability of these components.

In the auxiliary cooling system, the Flexible Coupling ensures a reliable connection between the pump and the engine, enabling efficient coolant circulation. This is vital for maintaining optimal engine temperature and preventing overheating.

For the injectors, the Flexible Coupling provides a stable yet flexible connection to the fuel system, ensuring consistent fuel delivery under varying engine conditions. This contributes to improved engine performance and fuel efficiency.

In the left bank and right bank aftercooler plumbing, the Flexible Coupling plays a key role in connecting the aftercooler to the engine and other components. It ensures that the compressed air is effectively cooled before entering the engine, which is essential for maintaining engine efficiency and performance.

The coupling also integrates with the manifold and exhaust system, allowing for flexible connections that can withstand the high temperatures and pressures generated during engine operation. This helps in reducing stress on the components and prolonging their lifespan.

Overall, the part 3635519 Flexible Coupling is a versatile component that enhances the reliability and performance of various engine systems by providing flexible, durable connections that can adapt to the dynamic conditions within an engine.

Conclusion

The Cummins 3635519 Flexible Coupling is a critical component in heavy-duty truck operations, ensuring efficient power transmission and accommodating misalignments. Its robust design, featuring high-quality materials and elastomeric inserts, contributes to durability and reduced maintenance needs. Proper installation and regular maintenance are essential for optimal performance. The coupling’s compatibility with various Cummins engine models underscores its versatility and reliability in diverse applications.

-

Hans B. Pacejka, Tyre and Vehicle Dynamics, Butterworth-Heinemann, 2006.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.