This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

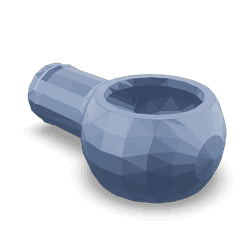

The 3596336 Banjo Connector Union, manufactured by Cummins, is a component designed for use in commercial trucks. It serves a specific purpose within the hydraulic and fuel systems of these vehicles. Cummins, a well-established name in the automotive industry, produces this part to ensure efficient and reliable operation of truck systems.

Basic Concepts of Banjo Connector Unions

A Banjo Connector Union is a type of fitting used to connect hoses or pipes in fluid systems. It typically consists of a bolt, a banjo fitting, and a gasket. The banjo fitting has a curved shape, resembling a banjo, which allows for flexibility in the connection. This design enables the fitting to accommodate slight misalignments between connected components, reducing stress on the system 1. In automotive and industrial settings, banjo connectors are commonly used in hydraulic, fuel, and brake systems due to their reliability and ease of installation.

Purpose and Function in Truck Operation

The 3596336 Banjo Connector Union plays a role in the operation of commercial trucks by facilitating the connection between various components within the hydraulic and fuel systems. It ensures a secure and leak-free connection, which is vital for the proper functioning of these systems. By maintaining consistent fluid flow, the banjo connector contributes to the overall performance and reliability of the vehicle. Its application in hydraulic systems allows for efficient operation of brakes and other hydraulically actuated components, while in fuel systems, it ensures that fuel is delivered to the engine under the correct pressure and flow rate 2.

Key Features

The 3596336 Banjo Connector Union is characterized by several key features that enhance its functionality and durability. It is constructed from high-quality materials, typically steel or stainless steel, which provide resistance to corrosion and wear. The design includes a precision-machined surface to ensure a tight seal with the mating components, and the use of a high-quality gasket material helps to prevent leaks. Additionally, the banjo fitting’s curved shape allows for flexibility in the connection, accommodating minor misalignments and reducing the risk of damage to the system.

Benefits

Using the 3596336 Banjo Connector Union in commercial trucks offers several advantages. It contributes to improved system efficiency by ensuring a secure and leak-free connection, which is crucial for the proper operation of hydraulic and fuel systems. The component’s robust construction and high-quality materials enhance its durability, leading to increased longevity. Furthermore, the design of the banjo connector promotes safety by reducing the risk of leaks and system failures, which could otherwise pose a hazard to the vehicle’s operation 3.

Installation Considerations

When installing the 3596336 Banjo Connector Union, it is important to follow guidelines and best practices to ensure a proper and secure connection. This may include adhering to specified torque values to avoid over-tightening, which could damage the fitting or the connected components. Proper alignment of the banjo fitting with the mating surface is also crucial to ensure a tight seal. Additionally, compatibility with other system components should be verified to ensure seamless integration into the truck’s hydraulic or fuel system.

Troubleshooting and Maintenance

Common issues associated with Banjo Connector Unions may include leaks, corrosion, or damage to the fitting or gasket. Troubleshooting steps may involve inspecting the connection for signs of wear or damage, checking for proper alignment, and ensuring that the torque specifications were followed during installation. Regular maintenance, such as periodic inspection and replacement of the gasket if necessary, can help to ensure the longevity and optimal performance of the 3596336 Banjo Connector Union.

Cummins: Manufacturer Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. With a strong presence in the automotive industry, Cummins is particularly renowned for its diesel engines and related components. The company has a long-standing commitment to quality and innovation, which is reflected in its product offerings, including the 3596336 Banjo Connector Union. Cummins’ focus on research and development ensures that its products meet the demanding requirements of commercial truck applications, providing reliable performance and durability.

Compatibility of Banjo Connector Union (Part 3596336) with Cummins Engines

The Banjo Connector Union (Part 3596336) by Cummins is designed to fit seamlessly with a range of Cummins engines, ensuring reliable and efficient performance. This part is integral to the engine’s operation, providing a secure connection for various fluid lines.

QSB5.9 CM850 and QSC8.3 CM850(CM2850)

The Banjo Connector Union is compatible with both the QSB5.9 CM850 and the QSC8.3 CM850(CM2850) engines. These engines are known for their robust construction and high performance, making them suitable for a variety of applications. The part’s design ensures a tight and leak-proof connection, which is crucial for maintaining the integrity of the engine’s hydraulic and fuel systems.

QSB6.7 M CM2250

Similarly, the QSB6.7 M CM2250 engine also benefits from the use of the Banjo Connector Union. This engine is part of Cummins’ lineup of medium-duty diesel engines, recognized for their durability and efficiency. The part’s precision engineering guarantees that it will fit perfectly, providing a reliable connection that can withstand the rigors of continuous operation.

Ensuring Optimal Performance

The Banjo Connector Union is a critical component in the engine’s system, and its compatibility with these Cummins engines ensures that the engines can operate at their best. Whether used in agricultural machinery, construction equipment, or other heavy-duty applications, this part plays a vital role in maintaining the engine’s performance and longevity.

Role of Part 3596336 Banjo Connector Union in Engine Systems

The 3596336 Banjo Connector Union is an essential component in the integration and functionality of various engine systems, particularly when dealing with aftermarket turbochargers and turbocharger kits.

When installing an aftermarket turbocharger, the Banjo Connector Union plays a significant role in ensuring the proper connection between the turbocharger and the engine’s oil supply system. This union facilitates the transfer of lubrication oil to the turbocharger’s bearings and other moving parts, which is vital for the turbocharger’s performance and longevity.

In the context of the turbine housing, the Banjo Connector Union is often used to connect the oil feed line to the turbocharger. This connection ensures that the turbine housing receives a consistent supply of oil, which is necessary for the efficient operation of the turbocharger.

For a comprehensive turbocharger kit, the Banjo Connector Union is a key component that ensures all oil lines are properly connected. This includes connections to the compressor side, the turbine side, and any additional oil lines required for the specific turbocharger model. Proper installation of the Banjo Connector Union in a turbocharger kit helps maintain the integrity of the oil system, preventing leaks and ensuring optimal performance of the turbocharger.

Overall, the Banjo Connector Union is integral to the efficient and reliable operation of turbochargers and turbocharger kits, providing essential oil connections that support the high-performance demands of these engine components.

Conclusion

The 3596336 Banjo Connector Union by Cummins is a critical component in the hydraulic and fuel systems of commercial trucks, ensuring secure and leak-free connections. Its robust construction, compatibility with various Cummins engines, and role in turbocharger systems highlight its importance in maintaining vehicle performance and reliability.

-

Heywood, John. Internal Combustion Engine Fundamentals. McGraw-Hill Education, 2019.

↩ -

Goodnight, Nicholas, and Kirk VanGelder. Automotive Braking Systems CDX Master Automotive Technician Series. Jones Bartlett Learning, 2019.

↩ -

Fijalkowski, BT. Automotive Mechatronics Operational and Practical Issues Volume 1. Springer, 2011.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.