This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

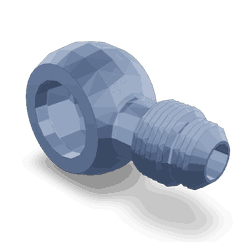

The 3281145 Banjo Connector by Cummins is a specialized component designed for use in commercial trucks. It plays a role in the operation of these vehicles by facilitating secure connections in fluid systems. This part is integral to maintaining the efficiency and reliability of hydraulic or fuel lines within the truck’s system.

Basic Concepts of Banjo Connectors

A banjo connector is a type of fitting used in fluid systems to join two pipes or hoses. It typically consists of a short, cylindrical body with fittings on each end. One end usually has a bolt or stud, while the other end features a threaded connection. In the context of a truck’s hydraulic or fuel system, the banjo connector allows for the transfer of fluids under pressure, ensuring a leak-free and secure connection 1.

Purpose of the 3281145 Banjo Connector

The 3281145 is specifically designed to play a role in the operation of commercial trucks by providing a reliable connection point in hydraulic or fuel lines. Its application ensures that fluids are delivered efficiently and without interruption, contributing to the overall performance and safety of the vehicle 2.

Key Features

The 3281145 is engineered with several design elements and materials that enhance its performance and durability. These include corrosion-resistant materials to withstand harsh operating environments, robust sealing mechanisms to prevent leaks, and various connection types to accommodate different system requirements. These features collectively contribute to the connector’s reliability and longevity 3.

Benefits of Using the 3281145 Banjo Connector

Utilizing the 3281145 offers several advantages. It contributes to improved system reliability by ensuring secure and leak-free connections. The design of the connector also facilitates ease of installation, reducing downtime during maintenance procedures. Additionally, its durable construction and sealing mechanisms enhance maintenance efficiency by minimizing the need for frequent replacements or repairs.

Installation Process

Proper installation of the 3281145 involves several steps to ensure a secure and leak-free connection. Begin by preparing the connection points on the hydraulic or fuel lines. Use the appropriate tools to tighten the connector, ensuring that it is snug but not over-tightened to avoid damage. Follow manufacturer guidelines for torque specifications to maintain the integrity of the connection.

Troubleshooting Common Issues

Typical problems that may arise with banjo connectors include leaks or connection failures. To address these issues, first, inspect the connection points for any signs of damage or wear. Ensure that the sealing surfaces are clean and free from debris. If a leak is detected, verify that the connector is properly tightened and that all components are in good condition. Replacement of worn or damaged parts may be necessary to resolve the issue.

Maintenance Tips

Regular maintenance practices can prolong the lifespan of the 3281145. Inspect the connector periodically for signs of wear, corrosion, or leaks. Clean the connection points as needed to remove any buildup that could affect performance. Following these maintenance tips will help ensure the continued reliability and efficiency of the connector within the truck’s system.

Cummins: A Brief Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes diesel and natural gas engines, as well as related technologies. With a history spanning over a century, Cummins is committed to innovation and excellence in the diesel engine and components industry. The company’s product range includes engines, filtration systems, powertrains, and emission solutions, all designed to meet the demanding requirements of commercial and industrial applications.

Cummins Banjo Connector 3281145 Compatibility

The Cummins Banjo Connector part number 3281145 is a versatile component designed to fit seamlessly within various Cummins engine models. This part is integral for maintaining fluid connections in the engine’s hydraulic and fuel systems.

Engine Compatibility

-

4B3.9 and 6B5.9 Engines: The 3281145 is specifically engineered to integrate with the 4B3.9 and 6B5.9 engines. These engines are known for their robust performance and reliability, often used in heavy-duty applications. The connector ensures a secure and leak-proof connection, critical for maintaining system integrity and performance.

-

6C8.3 Engine: Similarly, the 6C8.3 engine benefits from the use of the 3281145. This engine is another member of the Cummins lineup, recognized for its efficiency and durability. The connector’s design allows for easy installation and maintenance, ensuring that the engine operates at peak performance.

Installation and Usage

The 3281145 is designed for straightforward installation, making it an ideal choice for both professional mechanics and DIY enthusiasts. Its compatibility with multiple engine models simplifies inventory management and ensures that the correct part is readily available for maintenance and repair tasks.

By using the 3281145, technicians can ensure that their Cummins engines maintain optimal fluid flow, which is crucial for engine longevity and efficiency.

Role of Part 3281145 Banjo Connector in Engine Systems

The Banjo Connector, identified by part number 3281145, is a component in the integration and operation of various engine systems. Its primary function is to facilitate the secure connection between different plumbing components within the fuel system, ensuring efficient and reliable fuel transfer.

Fuel System Integration

In the fuel system, the Banjo Connector is utilized to link the fuel filter to the fuel transfer pump. This connection is vital for maintaining a consistent fuel flow from the fuel tank to the engine. The Banjo Connector ensures that the fuel lines are properly sealed, preventing any fuel leaks that could compromise engine performance or pose safety risks.

Fuel Filter and Pump Connection

The Banjo Connector plays a significant role in connecting the fuel filter to the fuel transfer pump. This connection is essential for the proper filtration of fuel before it reaches the engine. The secure fitting provided by the Banjo Connector ensures that the fuel filter can effectively remove impurities, protecting the fuel transfer pump and the engine from potential damage.

Fuel Transfer and Plumbing

Within the plumbing of the fuel system, the Banjo Connector is used to join various components such as the fuel drain location and the fuel pump transfer lines. This ensures that fuel can be efficiently transferred from the fuel tank to the engine, and any excess fuel can be properly drained. The Banjo Connector’s design allows for easy installation and removal, facilitating maintenance and repairs.

Accessories and Lift Pump

The Banjo Connector is also employed in connecting accessories within the fuel system, such as the lift pump. The lift pump is responsible for pressurizing the fuel before it reaches the main fuel pump. The secure connection provided by the Banjo Connector ensures that the lift pump can operate efficiently, contributing to the overall performance of the fuel system.

Overall System Efficiency

By ensuring secure and leak-free connections between various components of the fuel system, the Banjo Connector contributes to the overall efficiency and reliability of the engine. Its role in facilitating proper fuel flow, filtration, and transfer is indispensable for the smooth operation of the engine.

Conclusion

The 3281145 Banjo Connector by Cummins is a critical component in the maintenance and operation of commercial trucks and Cummins engines. Its design and features ensure secure, leak-free connections in hydraulic and fuel systems, contributing to the efficiency, reliability, and safety of the vehicle. Proper installation, regular maintenance, and troubleshooting of common issues are essential to maximize the performance and lifespan of this Cummins part.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.