Minimum Quantity 16

This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

The Connection Gasket 206435 is a specialized component designed by Cummins for use in heavy-duty truck systems. Its purpose is to provide a reliable seal between various engine components, ensuring optimal performance and efficiency. This Cummins part plays a significant role in maintaining the integrity of the engine’s sealing system, contributing to the overall functionality and durability of the truck.

Basic Concepts of Connection Gaskets

Connection gaskets are sealing components used in mechanical systems to prevent leaks between mating surfaces. They operate by filling the gaps between surfaces, ensuring that fluids or gases do not escape. Proper sealing is crucial for maintaining system pressure, efficiency, and safety. Connection gaskets are typically made from materials that can withstand high temperatures, pressures, and chemical exposure, ensuring long-term performance 1.

Purpose of the 206435 Connection Gasket

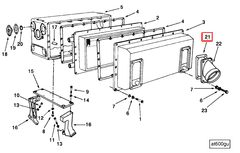

The 206435 Connection Gasket is specifically designed to fit within Cummins heavy-duty truck engines. It is placed between critical engine components to create a seal that prevents the escape of fluids or gases. This gasket ensures that the engine operates efficiently by maintaining proper pressure and preventing contamination from external elements. Its precise placement and function are vital for the engine’s performance and longevity.

Key Features

The 206435 Connection Gasket boasts several primary characteristics that enhance its performance and durability. It is composed of high-quality materials resistant to extreme temperatures and pressures. The design includes precise dimensions and surface treatments to ensure a perfect fit and optimal sealing. Additionally, the gasket may feature unique attributes such as reinforced edges or specialized coatings to improve its functionality in demanding environments.

Benefits

Using the 206435 Connection Gasket offers several advantages. It provides improved sealing efficiency, reducing the risk of leaks and maintaining system pressure. The gasket’s durable construction contributes to its longevity, minimizing the need for frequent replacements. Furthermore, its reliable performance enhances the overall reliability of the engine system, ensuring consistent operation under various conditions.

Installation Process

Proper installation of the 206435 Connection Gasket is crucial for its effectiveness. The process involves cleaning the mating surfaces to remove any debris or old gasket material. The gasket should be positioned correctly, ensuring it aligns with the designated areas. Tightening bolts or fasteners should be done in a specified sequence to achieve even pressure distribution. Careful attention to these steps helps avoid common pitfalls such as misalignment or over-tightening, which can compromise the gasket’s performance 2.

Troubleshooting and Maintenance

Identifying common issues with the 206435 Connection Gasket involves checking for signs of leaks, unusual engine noises, or performance drops. Diagnostic procedures may include visual inspections and pressure tests to pinpoint the source of the problem. Regular maintenance practices, such as periodic checks and cleaning, can help ensure the gasket remains in optimal condition. Addressing issues promptly can prevent more significant problems and extend the gasket’s lifespan.

Common Failure Modes

Typical failure scenarios for the 206435 Connection Gasket include wear due to prolonged use, improper installation, or exposure to harsh environmental conditions. Causes such as incorrect torque settings or contamination can also lead to gasket failure. Addressing these issues involves inspecting the gasket for damage, ensuring proper installation practices, and replacing the gasket if necessary to restore system integrity.

Replacement Guidelines

Replacing the 206435 Connection Gasket should be considered when signs of wear or failure are evident. These signs may include visible damage, persistent leaks, or decreased engine performance. Following the manufacturer’s guidelines for replacement ensures that the new gasket is installed correctly and functions effectively. Regular inspections can help identify the need for replacement before more severe issues arise.

Cummins Overview

Cummins Inc. is a renowned manufacturer in the automotive and heavy-duty truck industry. With a rich history of innovation and quality, Cummins offers a wide range of products designed to meet the demanding needs of various applications. The company’s reputation for reliability and performance makes its components, including the 206435 Connection Gasket, a preferred choice for professionals in the field.

Role of Part 206435 Connection Gasket in Engine Systems

The 206435 Connection Gasket is an essential component in ensuring the integrity and efficiency of various engine systems. Its primary function is to create a reliable seal between mating surfaces, preventing leaks and maintaining system pressure. Here’s how it integrates with several key components:

Aftercooler and Aftercooler Kit

In the aftercooler system, the Connection Gasket ensures a tight seal between the aftercooler and its housing. This is vital for efficient cooling of the compressed air from the turbocharger, enhancing overall engine performance and reliability. In an aftercooler kit, the gasket is often included to facilitate proper installation and function.

Turbocharger

When installed in a turbocharger arrangement, the Connection Gasket seals the connection points between the turbocharger and the engine. This prevents any exhaust gas leaks, which could lead to decreased turbocharger efficiency and potential engine damage.

Camshaft and Intake Manifold

In applications involving the camshaft and intake manifold, the Connection Gasket ensures that there are no air leaks between these components and the cylinder head. This is important for maintaining consistent air-fuel ratios and optimizing engine performance.

Overhaul Gasket Set and Lower/Upper Engine Gasket Set

During engine overhauls, the Connection Gasket is a key component in both lower and upper engine gasket sets. It provides essential seals at various points, such as between the cylinder head and engine block, and within the valve covers. This ensures that the engine operates efficiently without any unwanted leaks.

Performance and Performance Parts Kit

In performance applications, the Connection Gasket is often included in performance parts kits to ensure that upgraded components, such as high-flow intake manifolds or modified turbochargers, are properly sealed. This is important for maximizing the performance gains from these upgrades while maintaining engine reliability.

PDC (Precision Digital Control) Systems

In engines equipped with PDC systems, the Connection Gasket plays a role in sealing various sensor and control unit connections. This ensures accurate readings and efficient operation of the digital control systems, contributing to overall engine management and performance.

Conclusion

The 206435 Connection Gasket by Cummins is a critical component in maintaining the efficiency and reliability of heavy-duty truck engines. Its role in sealing various engine components ensures optimal performance, prevents leaks, and contributes to the longevity of the engine system. Proper installation, regular maintenance, and timely replacement are essential practices to ensure the gasket continues to function effectively.

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.