This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

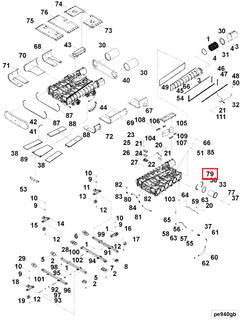

The 5419739 Connection Flange is a component manufactured by Cummins, a well-established name in the automotive and heavy-duty truck industry. This flange serves a specific purpose within the operational framework of heavy-duty trucks, contributing to the efficiency and reliability of the vehicle’s systems. Cummins, known for its commitment to quality and innovation, produces a range of parts designed to meet the demanding requirements of heavy-duty applications 1.

Basic Concepts of Connection Flanges

A connection flange is a type of fitting used in mechanical systems to join pipes, valves, and other components. Its general function is to provide a secure and leak-proof connection between different parts of a system. In the context of heavy-duty trucks, flanges play a vital role in ensuring that the various fluid systems, such as fuel, coolant, and hydraulic lines, are properly connected and sealed 2.

Purpose of the 5419739 Connection Flange

The 5419739 Connection Flange is designed to facilitate the connection between different components within a truck’s system. It ensures that these connections are secure, reducing the risk of leaks and enhancing the overall efficiency of the system. By providing a reliable interface between components, this flange contributes to the smooth operation of the truck 3.

Key Features

The 5419739 Connection Flange is characterized by several key features that enhance its functionality and durability. These include its material composition, which is selected for strength and resistance to corrosion, and its design specifications, which ensure a proper fit and seal. Additionally, any unique attributes, such as reinforced edges or specialized coatings, further contribute to its performance and longevity 4.

Benefits

Using the 5419739 Connection Flange offers several benefits. It provides improved sealing, which is crucial for preventing leaks in fluid systems. The design of the flange also facilitates ease of installation, reducing downtime during maintenance procedures. Furthermore, its durability ensures long-term performance, contributing to the overall efficiency and reliability of the truck’s system 5.

Installation Process

Proper installation of the 5419739 Connection Flange is critical for ensuring a secure and proper fit. The process involves several steps, including preparing the connection points, applying any necessary sealants, and using the appropriate tools to tighten the flange. Ensuring that the flange is correctly aligned and tightened to the specified torque is essential for achieving a leak-proof connection 6.

Maintenance Tips

Regular maintenance of the 5419739 Connection Flange is important for ensuring its longevity and optimal performance. This includes cleaning the flange and its connections to remove any debris or buildup, inspecting for signs of wear or damage, and replacing the flange if necessary. Adhering to a maintenance schedule helps prevent issues such as leaks or misalignment, ensuring the continued reliability of the truck’s systems 7.

Troubleshooting Common Issues

Common problems associated with connection flanges include leaks and misalignment. Troubleshooting these issues involves identifying the source of the problem, whether it be a damaged flange, improper installation, or wear and tear. Suggested steps for addressing these issues may include re-tightening the flange, applying additional sealant, or replacing the flange if it is damaged. In some cases, professional repair or replacement may be necessary to ensure the integrity of the connection 8.

Cummins: A Brief Overview

Cummins Inc. is a leading manufacturer in the automotive and heavy-duty truck industry, with a history of producing high-quality, innovative products. The company’s product range includes engines, filtration systems, and aftermarket parts, all designed to meet the demanding requirements of heavy-duty applications. Cummins is known for its commitment to quality, reliability, and customer satisfaction, making it a trusted name in the industry 9.

Cummins Connection Flange 5419739 Compatibility

The Cummins Connection Flange part number 5419739 is designed to fit seamlessly with a variety of Cummins engines, ensuring robust and reliable connections within the engine systems. This part is integral to maintaining the integrity and performance of the engines it is used with 10.

QSK95 and CM2350 Engines

The Connection Flange 5419739 is specifically engineered to integrate with the QSK95 and CM2350 engines. These engines are known for their high power output and reliability, often used in heavy-duty applications such as marine, construction, and power generation. The flange ensures that connections between various engine components are secure and leak-proof, which is crucial for the operational efficiency and longevity of these engines 11.

K113 Engine

Similarly, the K113 engine benefits from the use of the Connection Flange 5419739. This engine is typically employed in on-highway and vocational applications, where durability and performance are paramount. The flange’s design allows for precise alignment and secure fastening, which is essential for the smooth operation of the engine’s various systems 12.

Grouping of Engines

The QSK95 and CM2350 engines, while differing in specific applications, share a common need for high-performance connection solutions. The Connection Flange 5419739 is tailored to meet these needs, ensuring that both engines can operate at peak efficiency. The K113 engine, though used in different sectors, also relies on this flange to maintain the integrity of its connections, highlighting the versatility and broad applicability of the part across Cummins’ engine lineup 13.

Role of Part 5419739 Connection Flange in Engine Systems

The Part 5419739 Connection Flange is integral to the assembly and operation of various engine systems, particularly in the context of aftertreatment devices. This component facilitates the secure attachment of the aftertreatment device to the exhaust system, ensuring a robust and leak-free connection.

In the aftertreatment system, the Connection Flange plays a significant role by:

- Sealing the Exhaust Path: It creates a tight seal between the exhaust components and the aftertreatment device, preventing exhaust leaks that could reduce efficiency and increase emissions.

- Supporting Structural Integrity: The flange provides structural support, maintaining the alignment and stability of the aftertreatment device within the exhaust system.

- Enabling Maintenance Access: It allows for easier disassembly and reassembly of the aftertreatment device, which is essential for routine maintenance and repairs.

- Enhancing Thermal Management: By ensuring a proper fit, the flange helps in managing the thermal expansion and contraction of the exhaust components, contributing to the overall durability of the system.

- Facilitating Diagnostic Access: A well-fitted flange ensures that diagnostic tools can be accurately applied to the aftertreatment device, aiding in the detection and resolution of performance issues.

Conclusion

In summary, the 5419739 Connection Flange is a key component in maintaining the functional integrity and efficiency of the aftertreatment system within engine operations. Its design and features contribute to the secure and reliable connection of engine components, ensuring optimal performance and longevity of the engine systems.

-

Dixon, John. Modern Diesel Technology: Heating, Ventilation, Air Conditioning, Refrigeration, 2nd Edition. Cengage Learning, 2014.

↩ -

Rendle, Steve, and Randall, Martynn. Haynes Diesel Engine Systems and Data Book. Haynes Publishing, 2000.

↩ -

Gilles, Tim. Automotive Service: Inspection, Maintenance, Repair: 2nd Edition. Cengage Learning, 2020.

↩ -

Giles, Tim. Automotive Engines Diagnosis Repair and Rebuilding. Cengage Learning, 2019.

↩ -

Cummins Inc. QSF2.8 CM2880 F108, Service Manual (4332746).

↩ -

Cummins Inc. QSF2.8 CM2880 F108, Service Manual (4332746).

↩ -

Cummins Inc. QSF2.8 CM2880 F108, Service Manual (4332746).

↩ -

Cummins Inc. QSF2.8 CM2880 F108, Service Manual (4332746).

↩ -

Cummins Inc. QSF2.8 CM2880 F108, Service Manual (4332746).

↩ -

Cummins Inc. QSF2.8 CM2880 F108, Service Manual (4332746).

↩ -

Cummins Inc. QSF2.8 CM2880 F108, Service Manual (4332746).

↩ -

Cummins Inc. QSF2.8 CM2880 F108, Service Manual (4332746).

↩ -

Cummins Inc. QSF2.8 CM2880 F108, Service Manual (4332746).

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.