This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

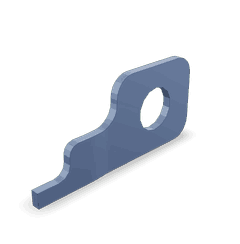

The Connection Bracket Assembly 5312129 is a specialized component designed by Cummins for use in heavy-duty truck systems. This assembly serves a pivotal role in ensuring the secure and efficient connection of various truck components, contributing to the overall functionality and reliability of the vehicle.

Basic Concepts

A Connection Bracket Assembly is a mechanical component used to link different parts of a vehicle together. In truck mechanics, these assemblies are crucial for maintaining the structural integrity and operational efficiency of the truck. They facilitate the secure attachment of components such as hoses, pipes, and electrical conduits, ensuring that they remain in place and function correctly under various driving conditions. The 5312129 integrates seamlessly with other truck components, providing a stable and durable connection point 1.

Purpose of the 5312129 Connection Bracket Assembly

This Cummins part is designed to play a specific role in the operation of a truck. It functions by connecting and supporting various truck components, ensuring they are held firmly in place. This assembly is particularly important in systems where vibrations and movements are common, as it helps to mitigate the effects of these forces on connected components. By providing a stable connection point, it contributes to the efficient operation of the truck’s systems.

Key Features

The 5312129 boasts several key features that enhance its performance and durability. It is constructed from high-quality materials, ensuring it can withstand the rigors of heavy-duty truck use. The design incorporates robust mounting points and secure attachment mechanisms, which facilitate easy installation and reliable operation. Additionally, the assembly may include unique attributes such as corrosion-resistant coatings or vibration-dampening elements, further enhancing its longevity and effectiveness.

Benefits

The advantages provided by the 5312129 are numerous. It offers improved structural integrity by securely holding components in place, which can lead to enhanced system performance. The design of the assembly also allows for ease of installation, reducing downtime during maintenance procedures. Furthermore, the durable construction and unique features of the assembly contribute to the increased longevity of connected components, providing long-term value to truck operators.

Installation Process

Proper installation of the 5312129 is vital for ensuring its effectiveness. The process involves several steps: first, identifying the correct location for the assembly on the truck; second, preparing the mounting surface to ensure a secure fit; third, attaching the assembly using the provided fasteners; and finally, verifying that all connections are secure and that the assembly is functioning as intended. Best practices include double-checking torque specifications for fasteners and ensuring that all connected components are properly aligned.

Troubleshooting

Common issues that may arise with the 5312129 include loose connections, corrosion, and damage from vibrations. Potential causes for these issues can range from improper installation to environmental factors. Recommended solutions or adjustments may involve re-tightening fasteners, applying corrosion-resistant coatings, or replacing damaged components. Regular inspections can help identify and address these issues before they lead to more significant problems.

Maintenance Tips

To ensure the longevity and optimal performance of the 5312129, regular maintenance practices are recommended. This includes routine inspections to check for signs of wear, corrosion, or loose connections. Cleaning the assembly and its surroundings can prevent the buildup of debris that may interfere with its function. Additionally, applying protective coatings or lubricants as needed can enhance its durability and performance.

Cummins Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes a wide range of power solutions, including engines, filtration, and emission solutions. With a strong reputation in the automotive industry, particularly in the heavy-duty truck sector, Cummins is known for its commitment to quality, innovation, and customer satisfaction. The company’s extensive product range and focus on technological advancement make it a trusted name in the industry.

Compatibility with Cummins Engines

The Connection Bracket Assembly part 5312129, manufactured by Cummins, is a critical component designed to fit seamlessly with several engine models. This part is integral to the structural integrity and operational efficiency of the engines it supports.

Compatible Engines

The 5312129 is compatible with the following engines:

- QSF2.8 CM2880 F104

- QSF2.8 CM2880 F105

- QSF2.8 CM2880 F114

This part ensures that the engine components are securely fastened and aligned, which is crucial for maintaining the engine’s performance and longevity. The design of the bracket assembly allows for precise mounting and alignment, reducing the risk of mechanical failure and ensuring smooth operation.

The bracket assembly is engineered to handle the specific stresses and vibrations inherent in these engines, providing a reliable connection point that can withstand the demands of heavy-duty applications. Its robust construction and precise fitment make it an essential part for the maintenance and repair of these engines.

By using the Connection Bracket Assembly part 5312129, technicians and engineers can ensure that the engines remain stable and operational, minimizing downtime and maximizing efficiency.

Role of Part 5312129 Connection Bracket Assembly in Engine Systems

In the context of engine systems, the 5312129 serves as an essential interface component, facilitating the integration and secure mounting of various engine components.

Integration with Plumbing Systems

When dealing with engine plumbing systems, the 5312129 is employed to anchor hoses, pipes, and fittings in place. This ensures that the fluid pathways—whether for coolant, fuel, or oil—remain stable and aligned under operational conditions. The bracket assembly supports the structural integrity of the plumbing network, minimizing the risk of leaks or disconnections that could arise from vibrations or thermal expansion.

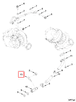

Application in Turbocharger Systems

In turbocharger systems, the 5312129 plays a significant role in securing the turbocharger to the engine block or manifold. This connection is vital for maintaining the turbocharger’s alignment with the exhaust and intake systems. The bracket assembly helps to absorb and distribute the forces generated by the high-speed rotation of the turbocharger, ensuring that the component remains firmly in place. This stability is important for the efficient operation of the turbocharger, as any misalignment could lead to decreased performance or even failure.

By providing a robust mounting solution, the 5312129 contributes to the overall reliability and performance of both plumbing and turbocharger systems within the engine.

Conclusion

The 5312129 Connection Bracket Assembly by Cummins is a vital component in heavy-duty truck systems, ensuring secure and efficient connections of various components. Its robust design, compatibility with specific engine models, and role in maintaining engine integrity highlight its importance in the automotive industry. Regular maintenance and proper installation are key to maximizing its performance and longevity.

-

Thompson, R. (2019). Automotive Maintenance: Light Repair. Cengage Learning.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.