5282475

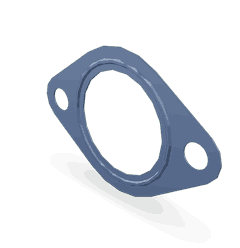

Connection Gasket

Cummins®

IN STOCK

More than 10 are currently available

Ships within 1 business day

This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

The Cummins 5282475 Connection Gasket is a specialized component designed for use in commercial trucks. Its purpose is to provide a reliable seal between various engine components, ensuring the efficient operation of the truck. This gasket plays a role in maintaining the integrity of the engine’s sealing system, which is important for the overall performance and longevity of the vehicle.

Basic Concepts of Connection Gaskets

Connection gaskets are sealing elements used between two or more mating surfaces to prevent the leakage of fluids or gases. They are integral to the operation of many mechanical systems, including engines, by ensuring that pressurized substances remain contained within their designated pathways. Connection gaskets are typically made from materials such as rubber, cork, graphite, or metal, chosen for their ability to withstand high temperatures, pressures, and chemical exposures 1.

Purpose of the Cummins 5282475 Connection Gasket

This Cummins part is specifically designed to seal connections within the engine or other systems of a truck. Its placement is important, often found between flanges or other components where a secure seal is necessary to prevent leaks. By maintaining a tight seal, this gasket helps to ensure that the engine operates efficiently, with minimal loss of fluids or gases.

Key Features

This part boasts several key features that enhance its performance. It is constructed from high-quality materials that offer excellent resistance to the harsh conditions found within a truck engine. The design of the gasket includes precise dimensions and surface finishes to ensure a perfect fit and optimal sealing capabilities. Additionally, any unique characteristics, such as reinforced edges or specialized coatings, further contribute to its durability and effectiveness.

Benefits

The advantages provided by this Cummins part include improved sealing efficiency, which leads to better engine performance and reduced maintenance costs. Its durability ensures a longer service life, minimizing the need for frequent replacements. Furthermore, the gasket’s contribution to overall system reliability helps to maintain the truck’s operational efficiency and safety.

Installation Process

Proper installation of this part is crucial for its effectiveness. The process involves cleaning the mating surfaces to ensure they are free from debris and contaminants. The gasket should be positioned correctly, with any alignment features matching up with the corresponding components. Tools required may include torque wrenches for tightening flanges to the manufacturer’s specifications. Following best practices, such as avoiding over-tightening, ensures a secure fit without damaging the gasket 2.

Troubleshooting Common Issues

Common problems associated with connection gaskets include leaks or failures, often due to improper installation, wear, or exposure to extreme conditions. Troubleshooting steps may involve inspecting the gasket for signs of damage, checking the tightness of the connection, and ensuring that the mating surfaces are clean and undamaged. Addressing these issues promptly can prevent more significant problems and maintain the efficiency of the truck’s engine.

Maintenance Tips

Regular maintenance of this part is recommended to ensure its continued effectiveness. Inspection intervals should be established based on the truck’s usage and operating conditions. Cleaning procedures may involve gently wiping the gasket and mating surfaces to remove any buildup without damaging the gasket. Replacement should be considered if signs of wear or failure are detected during inspections.

Manufacturer Information - Cummins

Cummins Inc. is a global power leader that designs, manufactures, and distributes a wide range of power solutions, including engines, filtration, and emissions solutions. With a strong reputation in the commercial truck industry, Cummins is known for its commitment to quality, innovation, and customer satisfaction. The company’s extensive product range and expertise in engine technology make it a trusted provider of components like the 5282475 Connection Gasket.

Connection Gasket Part 5282475 for Cummins Engines

The Connection Gasket part 5282475, manufactured by Cummins, is designed to fit seamlessly with the QSB3.3 CM2250 EC and QSB4.5 CM2250 EC engines. This gasket plays a role in ensuring a tight and leak-proof seal between engine components, which is important for maintaining optimal engine performance and longevity.

For the QSB3.3 CM2250 EC engine, the part 5282475 is engineered to fit precisely where it is needed, providing a reliable barrier against oil, coolant, and other fluids. Its design ensures that it can withstand the high pressures and temperatures typical of engine operations, thereby preventing any potential leaks that could compromise engine efficiency.

Similarly, in the QSB4.5 CM2250 EC engine, the Connection Gasket part 5282475 is crafted to meet the specific requirements of this engine model. It ensures that all connections are sealed properly, which is important for the engine’s overall functionality and durability. The gasket’s material and construction are optimized to handle the unique stresses and conditions present in this engine type.

Both engines benefit from the use of this gasket, as it is a component in maintaining the integrity of the engine’s sealing system. Its application is straightforward, and it integrates smoothly with the engine’s design, ensuring that all connections are secure and reliable.

Role of Part 5282475 Connection Gasket in Engine Systems

The Part 5282475 Connection Gasket is a component that ensures the integrity and efficiency of various engine systems. When integrated into a Complete Engine Gasket Kit, it plays a role in maintaining the seal between different engine components, preventing leaks and ensuring optimal performance.

In conjunction with a Hardware Kit, the Connection Gasket facilitates the secure attachment of various engine parts. This is particularly important in high-stress areas where vibrations and thermal expansion could otherwise lead to loosening or failure of connections.

For Plumbing systems within the engine, the Connection Gasket ensures that fluid pathways remain sealed. This is important for systems that handle coolant, oil, and other lubricants, as any leakage can lead to reduced efficiency and potential engine damage.

In Exhaust Recirculation (EGR) Systems, the Connection Gasket is used to seal the connections between the EGR valve, pipes, and the intake manifold. This ensures that exhaust gases are effectively recirculated back into the combustion chamber, reducing emissions and improving fuel efficiency.

The gasket also plays a role in Recirculation systems where fluids or gases are cycled through the engine for various purposes, such as cooling or emissions control. By providing a reliable seal, it helps maintain the intended flow and pressure within these systems.

Lastly, in Exhaust Systems, the Connection Gasket is employed to seal joints between exhaust manifolds, pipes, and catalytic converters. This not only prevents the escape of harmful gases but also maintains the backpressure needed for efficient engine operation.

Conclusion

The Cummins 5282475 Connection Gasket is a vital component in the maintenance and efficiency of commercial truck engines. Its proper installation, regular maintenance, and understanding of its role within various engine systems contribute to the overall performance and longevity of the vehicle. By ensuring a reliable seal between engine components, this gasket helps prevent leaks, maintain system integrity, and support the efficient operation of the truck.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.