This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

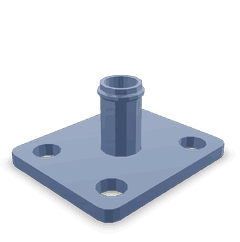

The Cummins 5272918 Connection Bracket is a specialized component designed for use in commercial truck operations. Its purpose is to facilitate secure connections between various parts of the truck, ensuring both structural integrity and efficient operation. Cummins Inc., the manufacturer of this bracket, is renowned in the industry for its commitment to innovation, quality, and reliability in diesel engine and related technologies 1.

Basic Concepts of Connection Brackets

Connection brackets serve as vital links in mechanical systems, providing the necessary support and stability for different components to work together seamlessly. In the automotive industry, these brackets are utilized in a wide range of applications, from engine mounts to chassis components, playing a significant role in the overall functionality and safety of vehicles 3.

Purpose of the 5272918 Connection Bracket

The 5272918 Connection Bracket is specifically designed to enhance the operational efficiency of trucks. It plays a role in connecting different components within the truck’s structure, ensuring that they remain securely in place under various driving conditions. This bracket contributes to the truck’s structural integrity and helps maintain the alignment and performance of connected parts 2.

Key Features

The 5272918 Connection Bracket boasts several key features that enhance its functionality and durability. It is constructed from high-quality materials, ensuring resistance to wear and corrosion. The design incorporates precise engineering to facilitate easy installation and secure fitting. Additionally, unique characteristics such as reinforced sections and optimized weight distribution contribute to its overall performance.

Benefits

Utilizing the 5272918 Connection Bracket offers several advantages. It improves the reliability of the truck’s structural connections, reducing the risk of component failure. The bracket’s design allows for straightforward installation, minimizing downtime during maintenance procedures. Furthermore, its contribution to the truck’s structural integrity and efficient operation enhances overall performance and safety on the road.

Installation Process

Proper installation of the 5272918 Connection Bracket is crucial for ensuring its effectiveness. The process involves several steps: first, identifying the correct location for the bracket within the truck’s structure; second, using appropriate tools to secure the bracket in place; and finally, verifying that the bracket is correctly aligned and tightly fastened. Following these steps ensures that the bracket functions as intended, providing the necessary support and stability.

Troubleshooting Common Issues

Common issues with connection brackets may include misalignment or wear over time. To address these problems, it is important to conduct regular inspections to identify any signs of damage or improper fitting. If misalignment is detected, adjusting the bracket’s position may resolve the issue. In cases of significant wear, replacement of the bracket is recommended to maintain structural integrity and safety.

Maintenance Tips

Regular maintenance is key to prolonging the life of the 5272918 Connection Bracket. This includes periodic inspections to check for signs of wear, corrosion, or damage. Cleaning the bracket and its surrounding areas can prevent the buildup of dirt and debris, which may affect its performance. Additionally, following manufacturer guidelines for inspection intervals and replacement schedules ensures that the bracket remains in optimal condition.

About Cummins

Cummins Inc. is a global leader in the design, manufacture, and distribution of diesel and natural gas engines, as well as related technologies. With a history spanning over a century, Cummins has established a reputation for innovation, quality, and reliability. The company’s product range includes engines, filtration systems, and power generation equipment, all designed to meet the demanding requirements of commercial and industrial applications. Cummins’ commitment to excellence is evident in their continuous investment in research and development, ensuring that their products remain at the forefront of technology and performance 1.

Role of Part 5272918 Connection Bracket in Engine Systems

The 5272918 Connection Bracket is an integral component in the assembly and operation of various engine systems, particularly those involving the compressor and air management.

In compressor systems, the Connection Bracket securely attaches the compressor to the engine frame, ensuring stability and proper alignment. This attachment is essential for the efficient transfer of mechanical energy from the engine to the compressor, facilitating the compression of air or refrigerant as required by the system. The secure fit provided by the bracket minimizes vibrations and potential misalignments, which could otherwise lead to inefficiencies or damage over time 2.

For air management systems, the Connection Bracket plays a significant role in connecting air ducts, hoses, and other components to the engine. It ensures that air flows smoothly and efficiently through the system, which is vital for maintaining optimal engine performance and cooling. The bracket’s design allows for easy attachment and detachment, facilitating maintenance and repairs without requiring extensive modifications to the engine setup 3.

Conclusion

The 5272918 Connection Bracket by Cummins is a critical component that enhances the structural integrity and operational efficiency of commercial trucks. Its design and features contribute to the reliable and safe operation of the vehicles it is installed in. Regular maintenance and proper installation are essential to ensure the longevity and effectiveness of this part.

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.