This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

The 5270180 Connection Gasket is a component manufactured by Cummins, a well-established name in the commercial truck industry. This gasket is specifically designed for use in heavy-duty truck engines, where it plays a role in maintaining the integrity of the engine’s sealing system. Connection gaskets, in general, are vital for ensuring that joints between various engine components remain sealed, preventing leaks and maintaining efficient operation 1.

Basic Concepts of Connection Gaskets

Connection gaskets serve the function of sealing the joints between different components within an engine. They are typically made from materials that can withstand high temperatures, pressures, and chemical exposures, such as rubber, cork, or metal. The primary role of these gaskets is to create a barrier that prevents the escape of fluids or gases, ensuring that the engine operates within its designed parameters 2.

Purpose of the 5270180 Connection Gasket

The 5270180 Connection Gasket is designed to fit within the engine system of compatible trucks, where it connects specific components. Its placement is crucial for maintaining the seal between these parts, which helps in preventing leaks of coolant, oil, or other fluids. By ensuring a tight seal, the gasket contributes to the overall efficiency and reliability of the engine 3.

Key Features

The 5270180 Connection Gasket features a design that is tailored to the specific requirements of heavy-duty truck engines. It is constructed from materials that offer durability and resistance to the harsh conditions found within an engine. The gasket’s design may include features such as reinforced edges or specific contours to ensure a perfect fit and optimal sealing performance 4.

Benefits

The use of the 5270180 Connection Gasket in a truck engine can lead to improved engine efficiency by maintaining proper seals and preventing leaks. This, in turn, can contribute to enhanced overall engine performance and reliability. Additionally, the gasket’s design and material properties help in reducing the risk of leaks, which can lead to engine damage or decreased performance 1.

Installation Process

Installing the 5270180 Connection Gasket requires careful attention to detail to ensure a secure fit. Preparatory steps may include cleaning the mating surfaces to remove any debris or old gasket material. The installation process should follow manufacturer guidelines, using the appropriate tools to avoid damaging the gasket or the components it connects. Best practices include torquing fasteners to the specified levels to ensure a proper seal without over-tightening 2.

Troubleshooting Common Issues

Common problems with connection gaskets can include leaks or failure due to wear and tear. Troubleshooting these issues may involve inspecting the gasket for signs of damage, such as cracks or deformation. If a leak is detected, the gasket may need to be replaced. Regular inspections can help in identifying potential issues before they lead to more significant problems 3.

Maintenance Tips

Regular maintenance of the 5270180 Connection Gasket is important for ensuring its continued performance. This may include periodic inspections for signs of wear, such as hardening or cracking. If any signs of degradation are observed, the gasket should be replaced to prevent leaks and maintain engine efficiency. Following the manufacturer’s recommended inspection intervals can help in prolonging the life of the gasket 4.

Cummins: A Brief Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. With a history spanning over a century, Cummins has established a reputation for quality and reliability in the commercial truck industry. The company offers a wide range of products and services designed to meet the needs of various industries, including transportation, construction, and agriculture.

Connection Gasket 5270180 by Cummins

The Connection Gasket 5270180, manufactured by Cummins, is a component designed to ensure a secure and leak-proof connection between various parts of the engine. This gasket is compatible with several Cummins engine models, providing a reliable seal that is essential for maintaining engine performance and efficiency.

Compatible Engines

- ISB4.5 CM2350 B104

- QSB3.3 CM2250 EC

- QSB4.5 CM2250 EC

- QSF3.8 CM2350 F107

Grouping by Engine Series

The Connection Gasket 5270180 is designed to fit seamlessly within the following engine series:

-

QSB Series

- QSB3.3 CM2250 EC

- QSB4.5 CM2250 EC

-

ISB Series

- ISB4.5 CM2350 B104

-

QSF Series

- QSF3.8 CM2350 F107

Each of these engines benefits from the gasket’s ability to create a tight seal, preventing any fluid or gas leaks that could compromise engine performance. The gasket’s material and design ensure it can withstand the high temperatures and pressures typical of these engines, making it a reliable choice for maintenance and repair 1.

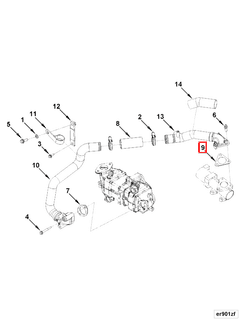

Role of Part 5270180 Connection Gasket in Engine Systems

In engine systems, the part 5270180 Connection Gasket is integral to ensuring the efficient and safe operation of various components.

Plumbing Systems

Within the plumbing systems of an engine, the Connection Gasket 5270180 is utilized to create a secure seal between different sections of the plumbing. This seal is essential for maintaining the integrity of fluid pathways, whether they are for coolant, oil, or other essential liquids. By preventing leaks, the gasket ensures that these fluids are directed correctly through the system, contributing to the overall efficiency and longevity of the engine 2.

Exhaust Recirculation (EGR) Systems

In Exhaust Recirculation (EGR) systems, the Connection Gasket 5270180 plays a significant role in maintaining the seal between the EGR valve and the intake manifold. This seal is vital for the proper recirculation of exhaust gases back into the intake, which helps in reducing nitrogen oxides (NOx) emissions. A well-sealed connection ensures that the recirculated gases are effectively mixed with the incoming air-fuel mixture, enhancing combustion efficiency and reducing harmful emissions 3.

Air Intake Systems

For air intake systems, the Connection Gasket 5270180 is employed to seal connections between the air filter housing and the intake manifold. This seal is important for maintaining the correct air-fuel ratio by preventing unmetered air from entering the system. A secure seal ensures that the engine receives the precise amount of air needed for optimal performance, thereby improving fuel efficiency and reducing the risk of engine damage due to incorrect air-fuel mixtures 4.

Conclusion

The 5270180 Connection Gasket by Cummins is a critical component in the maintenance and efficiency of heavy-duty truck engines. Its role in sealing various engine components ensures the prevention of leaks, maintains engine performance, and contributes to the overall reliability of the engine system. Regular maintenance and proper installation are key to maximizing the benefits of this Cummins part.

-

Automotive Technician Training, Second Edition, Tom Denton and Hayley Pells, Routledge, 2022

↩ ↩ ↩ -

A Field Guide to Automotive Technology, Ed Sobey, Chicago Review Press, 2009

↩ ↩ ↩ -

Design and Development of Heavy Duty Diesel Engines: A Handbook, P. A. Lakshminarayanan, Avinash Kumar Agarwal, Springer, 2019

↩ ↩ ↩ -

Light and Heavy Vehicle Technology, Fourth Edition, MJ Nunney, Butterworth-Heinemann, 2007

↩ ↩ ↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.