5260414

Connection Gasket

Cummins®

AVAILABLE

2 are currently available

Ships within 2-4 business days

This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

The Cummins 5260414 Connection Gasket is a specialized component designed for use in commercial trucks. Its purpose is to ensure a secure and reliable seal between various engine components, contributing to the overall efficiency and performance of the vehicle. This gasket plays a role in maintaining the integrity of the engine’s systems by preventing leaks and ensuring proper fluid and pressure management 1.

Basic Concepts of Connection Gaskets

Connection gaskets are sealing components used in mechanical systems to create a barrier between two or more surfaces. They are essential in preventing the escape of fluids, gases, or other materials from joints and connections. In various applications, connection gaskets contribute to the sealing process by filling the gaps between mating surfaces, thereby ensuring that the system operates efficiently without leaks 2.

Purpose of the 5260414 Connection Gasket

This Cummins part is specifically designed to play a role in the operation of a truck by sealing connections within the engine or other systems. It is typically placed between flanges or other mating surfaces where a secure seal is required. The gasket’s function is to maintain the integrity of the seal, preventing leaks of fluids or gases that could affect the engine’s performance.

Key Features

The 5260414 Connection Gasket features several key attributes that enhance its performance. It is composed of materials that offer durability and resistance to various operating conditions. The design of the gasket includes precise dimensions and surface finishes to ensure a proper fit and effective sealing. Additionally, it may incorporate unique characteristics such as reinforced edges or specific patterns to improve its sealing capabilities.

Benefits

The 5260414 Connection Gasket provides several benefits, including improved sealing efficiency and durability. Its design and material composition allow it to withstand high pressures and temperatures, ensuring a reliable seal over time. Compared to alternative gasket types, it offers enhanced performance and longevity, contributing to the overall efficiency of the truck’s engine.

Installation Process

Proper installation of the 5260414 Connection Gasket involves several steps to ensure a secure fit. Begin by cleaning the mating surfaces to remove any debris or old gasket material. Inspect the gasket for any damage before installation. Place the gasket between the flanges or mating surfaces, ensuring it is correctly aligned. Use the appropriate tools to tighten the connection gradually, avoiding over-tightening which could damage the gasket. Follow the manufacturer’s guidelines for torque specifications to achieve the best results.

Troubleshooting Common Issues

Common issues associated with connection gaskets include leaks or failures. To troubleshoot these problems, first, identify the source of the leak by inspecting the gasket and surrounding areas. Check for signs of wear, damage, or improper installation. If the gasket is damaged or worn, replacement may be necessary. Ensure that the mating surfaces are clean and free of debris before reinstalling a new gasket. Following the correct installation procedure can help prevent future issues.

Maintenance Tips

Regular maintenance of the 5260414 Connection Gasket is important to ensure its continued performance. Inspect the gasket during routine engine maintenance checks for signs of wear or damage. Clean the mating surfaces as needed to prevent debris from affecting the seal. Consider replacing the gasket if it shows significant wear or if leaks are detected. Adhering to these maintenance practices can help extend the life of the gasket and ensure the engine operates efficiently.

About Cummins

Cummins Inc. is a leading manufacturer of diesel and natural gas engines, as well as related technologies. With a history of innovation and quality, Cummins has established a strong reputation in the commercial truck industry. The company offers a wide range of products designed to meet the needs of various applications, ensuring reliable performance and efficiency for its customers.

Compatibility with Cummins Engines

The Connection Gasket 5260414, manufactured by Cummins, is designed to fit seamlessly with several of their engine models. This gasket is crucial for ensuring a secure and leak-proof connection between various engine components. Here’s how it integrates with specific Cummins engines:

QSB6.7 CM2250

The QSB6.7 CM2250 engine benefits from the Connection Gasket 5260414, which is essential for maintaining the integrity of the engine’s connections. This gasket is typically used in areas where two parts need to be joined securely, preventing any fluid or gas leaks that could compromise engine performance.

QSC9 CM2250/QSL9 CM2250

For the QSC9 CM2250 and QSL9 CM2250 engines, the Connection Gasket 5260414 plays a pivotal role in ensuring that the engine’s components are properly sealed. This gasket is integral in maintaining the engine’s operational efficiency by preventing leaks in critical areas. Its design allows for a precise fit, ensuring that the gasket performs optimally under the engine’s operating conditions.

By using the Connection Gasket 5260414, these engines can maintain their reliability and performance, as the gasket provides a dependable seal that is essential for the engine’s overall functionality.

Role of Part 5260414 Connection Gasket in Engine Systems

In the realm of engine systems, the part 5260414 Connection Gasket is integral to ensuring the efficient and reliable operation of various components. This gasket is specifically designed to create a secure seal between different parts, preventing leaks and maintaining system integrity.

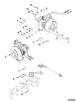

Turbocharger Systems

When it comes to turbochargers, the Connection Gasket is used within the Turbocharger Gasket Kit to seal the connections between the turbocharger and the engine. This ensures that the pressurized air from the turbocharger is effectively delivered to the engine’s intake system without any loss of pressure, which is essential for optimal performance.

Turbocharger Plumbing

In turbocharger plumbing, the Connection Gasket plays a significant role by sealing the various joints and connections. This is particularly important in high-pressure environments where even minor leaks can lead to a drop in efficiency and potential damage to the system. The gasket ensures that the flow of gases remains uninterrupted and within the designed parameters.

Upper Engine Gasket Kit

Within the Upper Engine Gasket Kit, the Connection Gasket is utilized to seal critical connections above the cylinder head. This includes sealing the intake manifold, exhaust manifold, and other upper engine components. By providing a reliable seal, the gasket helps maintain the integrity of the combustion process, ensuring that air and fuel mixtures are correctly managed and that exhaust gases are efficiently expelled.

General Plumbing Applications

In general plumbing applications within the engine system, the Connection Gasket is employed to seal various fluid passages. Whether it’s coolant, oil, or other fluids, the gasket ensures that these substances flow through the system without leakage. This is vital for maintaining the engine’s lubrication, cooling, and overall operational stability.

Overall, the part 5260414 Connection Gasket is a fundamental component in ensuring the seamless integration and operation of various engine systems, from turbochargers to upper engine components and general plumbing. Its role in creating secure seals is indispensable for the efficient and reliable performance of the engine.

Conclusion

The Cummins 5260414 Connection Gasket is a critical component in the maintenance and operation of commercial truck engines. Its role in sealing connections, preventing leaks, and ensuring system integrity is indispensable. Proper installation, regular maintenance, and understanding its compatibility with specific Cummins engines are essential for maximizing the performance and longevity of this gasket. By adhering to best practices and utilizing this part effectively, truck operators can ensure the reliable and efficient operation of their vehicles.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.