This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

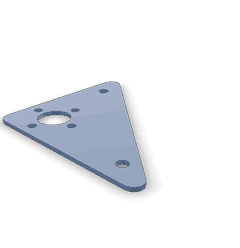

The Connection Bracket 4099510 is a component designed by Cummins for use in heavy-duty truck systems. Its primary role is to facilitate secure connections between various components and systems within the truck, ensuring efficient operation and structural integrity.

Purpose and Function

The Connection Bracket 4099510 serves to connect different parts of a heavy-duty truck’s system, allowing for the seamless transfer of fluids, gases, or mechanical forces. By providing a stable and reliable connection point, it helps maintain the integrity of the system, ensuring that components function as intended under various operating conditions 1.

Key Features

The Connection Bracket 4099510 is constructed from high-quality materials, typically including durable metals or robust polymers, which contribute to its longevity and performance. Its design incorporates features such as precision-machined surfaces for tight fits, corrosion-resistant coatings, and integrated mounting points that simplify installation and reduce the risk of misalignment. These characteristics enhance the bracket’s ability to withstand the rigors of heavy-duty applications 2.

Benefits

Utilizing the Connection Bracket 4099510 offers several advantages. It contributes to improved structural integrity by providing a solid connection between components, which is vital for the safe operation of heavy-duty trucks. The design of the bracket also facilitates ease of installation, reducing downtime during maintenance procedures. Additionally, by ensuring secure and precise connections, it enhances the overall efficiency of the truck’s systems 3.

Installation Process

Installing the Connection Bracket 4099510 requires careful attention to detail to ensure a secure fit. The process involves identifying the correct location for the bracket, preparing the surface for attachment, and using the appropriate tools to fasten the bracket in place. It is important to follow manufacturer guidelines to avoid damage to the bracket or surrounding components. Best practices include checking for proper alignment and torque specifications to ensure the connection is both secure and compliant with safety standards.

Maintenance and Troubleshooting

Regular maintenance of the Connection Bracket 4099510 is key to ensuring its continued performance. This includes periodic inspections for signs of wear, corrosion, or damage, and cleaning the bracket to remove any debris that could affect its function. Common issues may include loose connections or corrosion, which can often be addressed by tightening fasteners or applying a protective coating. If problems persist, consulting the manufacturer’s guidelines or a professional technician is recommended.

Safety Considerations

When working with the Connection Bracket 4099510, it is important to observe safety protocols to prevent injury or damage. This includes wearing appropriate personal protective equipment, ensuring the truck is properly supported during installation or maintenance, and being aware of potential hazards such as sharp edges or high-pressure systems. Following these safety considerations helps maintain a safe working environment.

Cummins Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. With a history of innovation and quality, Cummins is renowned for its commitment to producing reliable and efficient components for the automotive industry. The company’s extensive product line and reputation for excellence underscore its position as a leader in the field of engine and component manufacturing.

Cummins Connection Bracket 4099510 Compatibility

The Cummins Connection Bracket, part number 4099510, is a critical component designed to ensure the stability and proper alignment of various engine parts. This bracket is engineered to fit seamlessly with a range of Cummins engines, providing a robust connection point that enhances the overall performance and longevity of the engine.

KTA19 Series

The KTA19 series engines, including the KTA19GC, are known for their reliability and efficiency in industrial applications. The Connection Bracket 4099510 is specifically designed to integrate with these engines, ensuring that all connected components are securely fastened and properly aligned. This is crucial for maintaining the structural integrity of the engine and preventing any misalignment that could lead to operational issues.

Industrial and Power Generation Applications

In industrial and power generation settings, the KTA19GC engine is often used due to its robust design and high performance. The Connection Bracket 4099510 plays a vital role in these applications by:

- Ensuring secure attachment of various engine components.

- Providing a stable connection point that can withstand the rigors of continuous operation.

- Enhancing the overall reliability and efficiency of the engine.

By using the Connection Bracket 4099510, technicians and engineers can be confident that their KTA19GC engines will operate smoothly and efficiently, with all components securely fastened and properly aligned. This part is a testament to Cummins’ commitment to quality and durability, ensuring that their engines perform at their best in demanding environments.

Role of Part 4099510 Connection Bracket in Engine Systems

The part 4099510 Connection Bracket is integral to the assembly and operation of several key components within engine systems. It serves as a pivotal interface that ensures the secure and efficient connection between various parts, facilitating smooth and reliable engine performance.

Integration with Control Linkage Bracket

The Connection Bracket works in tandem with the Control Linkage Bracket to establish a robust linkage system. This system is responsible for transmitting mechanical movements from the control mechanisms to the engine’s operational components. The secure attachment provided by the Connection Bracket ensures that the Control Linkage Bracket remains firmly in place, allowing for precise and consistent control over engine functions.

Governor Mounting

In the context of Governor Mounting, the Connection Bracket plays a significant role. It provides a stable mounting point for the governor, which is essential for regulating engine speed. By ensuring a solid connection, the Connection Bracket helps maintain the governor’s alignment and operational integrity, contributing to the engine’s ability to maintain consistent performance under varying loads.

Linkage System

The Connection Bracket is also a vital component in the overall Linkage System. It connects various linkage components, enabling the transfer of mechanical force and motion throughout the engine. This integration is essential for synchronizing the movements of different engine parts, ensuring that they operate in harmony to achieve optimal performance.

Governor Control

Lastly, the Connection Bracket is instrumental in the Governor Control mechanism. It facilitates the connection between the governor and other control elements, allowing for fine-tuned adjustments to engine speed and performance. The reliable connection provided by the Connection Bracket ensures that the Governor Control system can respond accurately to changes in engine conditions, enhancing overall engine efficiency and responsiveness.

Conclusion

The Connection Bracket 4099510 by Cummins is a critical component in heavy-duty truck systems, ensuring secure and efficient connections between various engine components. Its high-quality construction, ease of installation, and maintenance benefits make it a valuable part for maintaining the structural integrity and performance of heavy-duty engines. By understanding its role and proper usage, technicians and engineers can ensure optimal engine operation and longevity.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.