4007850

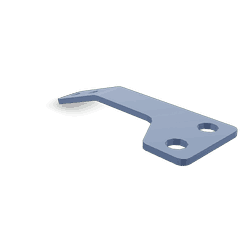

Connection Bracket

Cummins®

AVAILABLE

2 are currently available

Ships within 2-4 business days

This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

The Connection Bracket 4007850, manufactured by Cummins, is a critical component in the commercial truck industry. This bracket is designed to facilitate secure connections between various truck components, ensuring operational efficiency and safety. Cummins is known for its commitment to quality and innovation, ensuring that this part meets high standards of performance and reliability 1.

Purpose and Function

This Cummins part plays a significant role in the operational efficiency of commercial trucks by providing a secure and stable connection point for various components. It ensures that parts are held firmly in place, which is essential for the safe and effective operation of the truck. The bracket contributes to maintaining the structural integrity and functional alignment of connected components, enhancing the overall performance and safety of the vehicle 2.

Key Features

The Connection Bracket 4007850 is characterized by several key features that enhance its functionality. It is constructed from durable materials to withstand the rigors of commercial truck operations. The design includes precise engineering for a snug fit and secure connection. Additionally, it may feature corrosion resistance or ease of installation, contributing to its effectiveness in truck applications 3.

Benefits

The use of the Connection Bracket 4007850 offers several benefits. Its robust construction and secure fitting contribute to improved stability and reliability of the connected components. The ease of installation reduces downtime during maintenance or repairs. Furthermore, its durability ensures long-term performance, minimizing the need for frequent replacements. These benefits collectively contribute to enhanced truck performance and reduced maintenance costs.

Installation Process

Installing the Connection Bracket 4007850 requires careful attention to ensure proper fit and function. The process involves securing the bracket to the designated location on the truck, using the appropriate fasteners provided. It is important to follow the manufacturer’s guidelines for installation to ensure safety and effectiveness. Tools required may include a wrench or socket set, depending on the specific design of the bracket.

Maintenance Tips

Regular maintenance of the Connection Bracket 4007850 is important to ensure its longevity and optimal performance. This includes periodic checks for signs of wear or damage, ensuring all fasteners are secure, and cleaning the bracket to remove any debris or corrosion. Adhering to a routine maintenance schedule helps identify potential issues early, allowing for timely repairs or replacements.

Troubleshooting Common Issues

Common issues with the Connection Bracket 4007850 may include loosening of fasteners, corrosion, or physical damage. Troubleshooting steps involve inspecting the bracket for any visible signs of wear, tightening any loose fasteners, and cleaning the area to remove corrosion. If damage is detected, it may be necessary to replace the bracket. Professional repair or replacement should be sought if the issue cannot be resolved through basic troubleshooting.

Compatibility and Usage

The Connection Bracket 4007850 is designed for use with specific types of trucks and engine models. Its application varies depending on the truck configuration and the specific components it is intended to connect. Understanding the compatibility of this bracket with your truck is important for ensuring proper fit and function.

Safety Considerations

When installing, maintaining, or troubleshooting the Connection Bracket 4007850, it is important to adhere to safety guidelines. This includes ensuring the truck is properly secured and the engine is off during installation or maintenance. Following manufacturer recommendations and safety protocols helps prevent accidents and ensures the safe and effective use of the bracket.

Cummins Overview

Cummins Inc. has a long-standing reputation in the commercial truck industry for producing high-quality components. Founded with a commitment to innovation and excellence, Cummins offers a wide range of products designed to enhance the performance and reliability of commercial vehicles. Their dedication to quality is evident in every component they manufacture, including the Connection Bracket 4007850.

Cummins Connection Bracket 4007850 Compatibility

The Cummins Connection Bracket part number 4007850 is designed to integrate seamlessly with a range of Cummins engines, ensuring robust and reliable performance. This part is particularly compatible with the following engines:

-

QSK78 Series: The Connection Bracket 4007850 is engineered to fit perfectly with the QSK78 engines, providing a stable connection point for various components. This ensures that the engine operates smoothly and efficiently, maintaining its high performance standards.

-

CM500 Series: Similarly, the Connection Bracket 4007850 is also suitable for the CM500 engines. Its design allows for precise alignment and secure attachment, which is crucial for the engine’s operational integrity.

These engines are known for their durability and efficiency, and the Connection Bracket 4007850 plays a vital role in maintaining these qualities. By ensuring that all components are securely fastened, this bracket helps to prevent any potential issues that could arise from loose connections, thereby enhancing the overall reliability of the engine.

Role of Part 4007850 Connection Bracket in Engine Systems

The part 4007850 Connection Bracket is an essential component in the integration and secure mounting of various engine systems. Its primary function is to provide a stable and reliable connection point for multiple components, ensuring they operate efficiently and safely within the engine environment.

Integration with Plumbing Systems

In plumbing systems associated with engine operations, the Connection Bracket plays a significant role in securing pipes and hoses. It ensures that these components remain firmly in place, minimizing the risk of leaks or disconnections that could lead to system failures. The bracket facilitates the organization and routing of plumbing lines, allowing for easier maintenance and inspection. It also helps in absorbing vibrations that might otherwise cause wear and tear on the plumbing connections.

Support for Turbocharger Oil Systems

When it comes to turbocharger oil systems, the Connection Bracket is instrumental in supporting the oil lines that supply lubricant to the turbocharger. This support is vital for maintaining the integrity of the oil supply under high-pressure conditions. The bracket ensures that the oil lines are correctly aligned and secured, which is important for the consistent delivery of oil to the turbocharger bearings. This consistent lubrication is key to the turbocharger’s performance and longevity, as it reduces friction and wear within the turbocharger assembly.

Overall System Stability

Across both plumbing and turbocharger oil systems, the Connection Bracket contributes to the overall stability of the engine systems. By providing a robust mounting solution, it helps in maintaining the alignment and integrity of various components. This stability is particularly important in high-performance engines where precision and reliability are paramount. The bracket’s role in securing and organizing these systems allows for more efficient engine operation and easier troubleshooting in case of issues.

Conclusion

The Connection Bracket 4007850 by Cummins is a vital component in the commercial truck industry, ensuring secure and reliable connections between various engine components. Its robust construction, ease of installation, and compatibility with specific Cummins engines make it an essential part for maintaining the performance and safety of commercial trucks. Regular maintenance and adherence to safety guidelines are important for maximizing the longevity and effectiveness of this part.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.