This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

The Cummins 4007412 Connection Bracket is a component designed for use in commercial trucks. It serves a specific function within the truck’s mechanical system, contributing to the overall efficiency and reliability of the vehicle. Understanding its purpose and significance is key to maintaining and optimizing the performance of commercial trucks.

Basic Concepts of Connection Brackets

Connection brackets are mechanical components used to link various parts of a system together. They provide structural support and ensure that components remain aligned and function correctly. In the context of commercial trucks, these brackets play a role in securing and aligning critical parts, facilitating the smooth operation of the vehicle 1.

Purpose of the 4007412 Connection Bracket

The 4007412 Connection Bracket is designed to connect specific components within a truck’s mechanical system. Its role involves ensuring that these components are properly aligned and secured, which contributes to the efficient operation of the truck. By maintaining the correct positioning of parts, this bracket helps in the reliable functioning of the truck’s systems 2.

Key Features

The 4007412 Connection Bracket is constructed from durable materials, ensuring it can withstand the rigors of commercial truck operation. Its design includes features that enhance its functionality, such as precise fitting dimensions and robust construction. These characteristics contribute to the bracket’s ability to perform its role effectively within the truck’s mechanical system 3.

Benefits of Using the 4007412 Connection Bracket

Utilizing the 4007412 Connection Bracket offers several advantages. Its durable construction contributes to the longevity of the component, reducing the need for frequent replacements. The design of the bracket also facilitates ease of installation, allowing for quick and efficient setup. Additionally, by ensuring proper alignment and secure connection of components, it enhances the overall performance and reliability of the truck’s mechanical system.

Installation Process

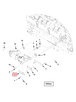

Installing the 4007412 Connection Bracket requires following a series of steps to ensure proper fitting. The process involves preparing the area where the bracket will be installed, aligning the bracket with the components it will connect, and securing it in place using the appropriate tools. Careful attention to these steps ensures that the bracket functions as intended within the truck’s system.

Maintenance and Troubleshooting

Regular maintenance of the 4007412 Connection Bracket is important to ensure its continued reliable operation. This includes checking for signs of wear or damage and addressing any issues promptly. Common problems may include misalignment or loosening of the bracket, which can be resolved through re-alignment or re-securing the bracket. Regular inspections and maintenance help in identifying and addressing potential issues before they lead to more significant problems.

Manufacturer: Cummins

Cummins is a well-established manufacturer in the commercial truck industry, known for its range of high-quality products. The company has a history of innovation and reliability, providing components that contribute to the efficient operation of commercial vehicles. Their products, including the 4007412 Connection Bracket, are designed with a focus on durability, performance, and ease of use, reflecting Cummins’ commitment to quality and customer satisfaction.

Role of Part 4007412 Connection Bracket in Engine Systems

The 4007412 Connection Bracket is an integral component in the assembly and functionality of various engine systems. It serves as a pivotal link between the filter and the lubricating oil system, ensuring a secure and efficient connection.

Integration with the Filter

In engine systems, the filter plays a significant role in maintaining the quality of the lubricating oil by removing contaminants. The 4007412 Connection Bracket facilitates the attachment of the filter to the engine, providing a stable and reliable connection. This ensures that the filter is correctly positioned and can effectively perform its filtering duties without the risk of detachment or misalignment.

Lubricating Oil System

The lubricating oil system is essential for reducing friction and wear within the engine components. The 4007412 Connection Bracket is instrumental in connecting the lubricating oil filter to the oil passages within the engine. This connection ensures that the oil flows smoothly through the filter, getting cleaned before it circulates through the engine. The bracket’s design allows for easy maintenance and replacement of the filter, which is vital for the ongoing efficiency of the lubricating oil system.

Mounting Considerations

Proper mounting of engine components is key to the overall performance and longevity of the engine. The 4007412 Connection Bracket provides a robust mounting solution for the lubricating oil filter. It ensures that the filter is securely fastened, minimizing vibrations and potential leaks. This stable mounting is essential for maintaining the integrity of the lubricating oil system and preventing any disruptions in oil flow.

Lubricating Oil Filter Efficiency

The efficiency of the lubricating oil filter is greatly enhanced by the secure connection provided by the 4007412 Connection Bracket. By ensuring a tight and consistent connection, the bracket helps maintain the filter’s effectiveness in trapping contaminants. This, in turn, contributes to the overall cleanliness of the lubricating oil, promoting better engine performance and longevity.

Conclusion

The 4007412 Connection Bracket, manufactured by Cummins, is a critical component in the assembly of several engine models. This bracket is designed to ensure secure and stable connections between various engine parts, enhancing the overall structural integrity and operational efficiency of the engines. Its role in maintaining alignment and stability, as well as its contribution to the efficient functioning of the filter and lubricating oil system, underscores its importance in the maintenance and performance of commercial trucks.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.