This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

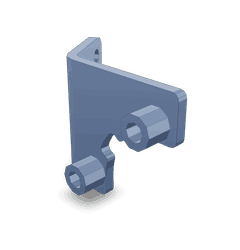

The Connection Bracket 4007261, manufactured by Cummins, is a component designed for use in commercial trucks. Cummins, a well-established name in the automotive industry, is known for producing reliable and high-performance parts. This Cummins part is significant within the realm of commercial truck components due to its role in ensuring the structural integrity and operational efficiency of the vehicles it is installed in.

Basic Concepts of Connection Brackets

Connection brackets are mechanical components used to join different parts of a system together. They play a role in maintaining the alignment and stability of various components, contributing to the overall structural integrity and operational efficiency of vehicles. By securely fastening parts, connection brackets help distribute loads and stresses evenly, which is vital for the longevity and performance of mechanical systems 1.

Purpose of the 4007261 Connection Bracket

The 4007261 Connection Bracket is specifically designed to play a role in the mechanical system of a truck. It functions by providing a secure attachment point for various components, ensuring they remain in the correct position under operational conditions. This bracket contributes to the stability and alignment of parts within the truck’s system, which is important for the vehicle’s performance and safety 2.

Key Features

The 4007261 Connection Bracket is constructed from high-quality materials, ensuring durability and resistance to wear and tear. Its design includes features such as precision-machined mounting points and robust construction, which enhance its performance and longevity. These characteristics are important for withstanding the demanding conditions encountered in commercial truck operations 3.

Benefits

The 4007261 Connection Bracket offers several benefits, including improved structural support for connected components, enhanced durability due to its material composition, and contributions to the overall efficiency and safety of the truck. By ensuring components are securely fastened and correctly aligned, this bracket helps maintain the truck’s performance and reliability over time.

Installation Process

Installing the 4007261 Connection Bracket requires careful attention to ensure it is correctly fitted and functions as intended. The process involves securing the bracket to the designated mounting points using the appropriate fasteners. It is important to follow the manufacturer’s guidelines for installation to ensure the bracket is properly aligned and tightened, which is important for its effectiveness and the safety of the vehicle.

Troubleshooting and Maintenance

Common issues with the 4007261 Connection Bracket may include loosening of fasteners or wear on the bracket itself. Regular inspections can help identify these problems early, allowing for timely maintenance or replacement. Recommended practices include checking the tightness of fasteners and inspecting the bracket for signs of damage or wear, which can help prolong its life and effectiveness.

Cummins: Manufacturer Overview

Cummins is a reputable manufacturer in the automotive industry, known for its high-quality products designed for commercial trucks. With a history of innovation and commitment to excellence, Cummins offers a wide range of components that contribute to the performance and reliability of commercial vehicles. Their products are trusted by professionals in the industry for their durability and efficiency.

Compatibility with Cummins Engines

The Connection Bracket 4007261 is designed to fit seamlessly with a range of Cummins engines. This bracket is integral for ensuring proper alignment and stability of various engine components.

QSK45 CM500 and QSK60 CM500

The Connection Bracket 4007261 is compatible with both the QSK45 CM500 and QSK60 CM500 engines. These engines are part of Cummins’ QSK series, known for their robust performance and reliability in heavy-duty applications. The bracket’s design ensures it fits precisely with the mounting points on these engines, facilitating efficient operation and maintenance.

QSK60G

The QSK60G engine also integrates the Connection Bracket 4007261 effectively. This engine is part of the same QSK series, offering high power output and durability. The bracket’s compatibility with the QSK60G ensures that it maintains the structural integrity of the engine, supporting various components and ensuring smooth operation.

QSK78 CM500

The Connection Bracket 4007261 is also suitable for the QSK78 CM500 engine. This engine, like its counterparts, benefits from the bracket’s precise fit, which is crucial for maintaining the alignment and stability of the engine’s components. The bracket’s design allows for easy installation and reliable performance, making it an essential part for the QSK78 CM500.

Grouping of Engines

The Connection Bracket 4007261 is designed to fit the QSK series engines, which include the QSK45 CM500, QSK60 CM500, QSK60G, and QSK78 CM500. This grouping highlights the bracket’s versatility and compatibility across different engine models within the same series. The bracket’s design ensures it meets the specific requirements of each engine, providing a reliable and efficient solution for maintaining engine integrity.

Role of Part 4007261 Connection Bracket in Engine Systems

The 4007261 Connection Bracket is integral to the seamless operation of various engine systems. It serves as a pivotal junction point, facilitating the secure attachment of multiple components, ensuring stability and efficient performance.

Integration with Electrical Components

In electrical systems, the Connection Bracket securely mounts resistors, which are vital for controlling the flow of electrical current. By providing a stable platform, it ensures that resistors remain in optimal position, minimizing the risk of electrical faults and enhancing the reliability of the engine’s electrical circuits.

Corrosion Prevention

The Connection Bracket also plays a significant role in corrosion prevention. It is often used to attach components in areas prone to moisture and chemical exposure. By ensuring a firm and consistent connection, it helps to maintain the integrity of the engine’s components, reducing the likelihood of corrosion that can lead to system failures.

Structural Support

Beyond its electrical and corrosion-resistant functions, the Connection Bracket offers essential structural support. It helps in maintaining the alignment of various engine parts, which is necessary for the smooth operation of the engine. This support is particularly important in high-vibration environments, where component misalignment can lead to increased wear and potential damage.

Enhanced Maintenance Accessibility

The use of the Connection Bracket also improves maintenance accessibility. By providing a clear and organized attachment point for various components, it simplifies the process of inspecting, repairing, or replacing parts. This not only saves time during maintenance but also reduces the risk of errors, ensuring that the engine system remains in peak condition.

Conclusion

In summary, the 4007261 Connection Bracket is a versatile and essential component in engine systems, contributing to electrical stability, corrosion resistance, structural integrity, and maintenance efficiency. Its compatibility with a range of Cummins engines underscores its importance in ensuring the performance and reliability of commercial trucks.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.