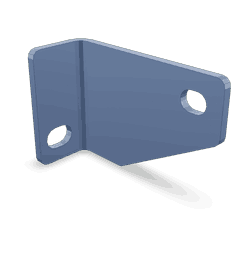

4007216

Connection Bracket

Cummins®

AVAILABLE

More than 10 are currently available

Ships within 2-4 business days

This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

The 4007216 Connection Bracket is a component manufactured by Cummins, a well-established name in the automotive industry. This bracket holds significance in commercial truck operations due to its role in ensuring the secure and efficient connection of various parts within the truck’s mechanical system.

Basic Concepts of Connection Brackets

Connection brackets serve as vital links in mechanical systems, facilitating the secure attachment of components to one another. In the context of heavy-duty trucks, these brackets are crucial for maintaining the structural integrity and operational efficiency of the vehicle. They allow for the proper alignment and support of parts, which is essential for the smooth functioning of the truck 1.

Purpose of the 4007216 Connection Bracket

This Cummins part plays a role in the operation of a truck by providing a stable connection point for various components. It integrates with other parts of the truck’s system to ensure that all elements are securely fastened and correctly aligned. This bracket is designed to withstand the rigors of heavy-duty use, contributing to the overall reliability and performance of the truck.

Key Features

The 4007216 Connection Bracket is characterized by several key features that enhance its functionality. It is made from durable materials that can resist wear and tear, ensuring long-lasting performance. The design of the bracket includes precise engineering to allow for easy installation and a secure fit. Additionally, it may feature unique attributes such as corrosion resistance or specific mounting points that cater to the demands of heavy-duty applications.

Benefits

The advantages of using the 4007216 Connection Bracket include improved durability, which reduces the need for frequent replacements. Its design also facilitates ease of installation, saving time during maintenance or repair work. Fleet operators may experience potential cost savings due to the bracket’s longevity and the reduction in downtime associated with its use.

Installation Process

To install the 4007216 Connection Bracket, one should follow a step-by-step process that includes gathering the necessary tools, such as wrenches and screwdrivers. The bracket should be aligned with the designated mounting points on the truck, and then secured using the appropriate fasteners. It is important to follow best practices to ensure a correct fit, which may include checking for proper alignment and torque specifications for the fasteners.

Maintenance Tips

Regular maintenance of the 4007216 Connection Bracket is recommended to ensure its longevity and reliable performance. This includes periodic inspection for signs of wear or damage, and cleaning the bracket to remove any debris that could affect its function. Adhering to manufacturer-recommended inspection intervals will help in identifying any issues before they become problematic.

Troubleshooting Common Issues

Common problems associated with the 4007216 Connection Bracket may include loosening of fasteners or corrosion. When these issues arise, it is advisable to tighten the fasteners to the specified torque and apply a corrosion-resistant coating if necessary. If the bracket shows signs of significant wear, it should be replaced to maintain the integrity of the truck’s mechanical system.

Safety Considerations

When working with the 4007216 Connection Bracket, it is important to observe safety guidelines and precautions. This includes wearing personal protective equipment (PPE) such as gloves and safety glasses. Safe handling practices should be followed to prevent injury, which may involve ensuring the truck is properly supported on a level surface before beginning any work.

Cummins: A Brief Overview

Cummins is a manufacturer with a strong reputation in the industry for producing high-quality automotive components. With a history of innovation and a commitment to quality, Cummins has established itself as a trusted provider of parts that contribute to the efficiency and reliability of commercial vehicles. Their products, including the 4007216 Connection Bracket, are designed with the expertise and precision that Cummins is known for.

Compatibility with Cummins Engines

The Connection Bracket part number 4007216, manufactured by Cummins, is designed to integrate seamlessly with a variety of Cummins engine models. This bracket is a critical component in ensuring the structural integrity and proper alignment of engine parts.

QSK45 CM500 and QSK60 CM500

The Connection Bracket 4007216 is compatible with the QSK45 CM500 and QSK60 CM500 engines. These engines are part of Cummins’ QSK series, known for their robust performance and reliability in various industrial applications. The bracket’s design ensures it fits precisely with the mounting points and alignment requirements of these engines, facilitating smooth operation and reducing the risk of mechanical failure.

QSK60 CM850 MCRS and QSK60 G CM2358 K110

The Connection Bracket 4007216 also fits the QSK60 CM850 MCRS and QSK60 G CM2358 K110 engines. These engines are part of the QSK60 series, which includes models with higher power outputs and advanced features. The bracket’s precision engineering ensures it aligns perfectly with the specific mounting points of these engines, contributing to the overall stability and efficiency of the engine system.

QSK60G

The Connection Bracket 4007216 is also suitable for the QSK60G engine. This model is part of the QSK60 series and is designed for high-performance applications. The bracket’s compatibility with the QSK60G ensures that it meets the stringent demands of this engine, providing reliable support and alignment.

QSK78 CM500

Lastly, the Connection Bracket 4007216 is compatible with the QSK78 CM500 engine. This engine is part of the QSK78 series, which is known for its exceptional power and efficiency. The bracket’s design ensures it fits seamlessly with the QSK78 CM500, contributing to the engine’s overall performance and durability.

Role of Part 4007216 Connection Bracket in Engine Systems

The part 4007216 Connection Bracket is integral to the efficient operation of various engine systems. It serves as a pivotal interface that facilitates the secure attachment of the water pump to the engine block. This bracket ensures that the water pump is correctly aligned and firmly held in place, which is essential for the pump’s performance.

In the context of the water pump arrangement, the Connection Bracket allows for the proper routing of coolant hoses. It supports the hoses and helps maintain their integrity under operational stress, ensuring a consistent flow of coolant throughout the engine system. This consistent flow is vital for maintaining optimal engine temperature and preventing overheating 2.

Additionally, the bracket plays a role in the overall pump arrangement by providing a stable foundation. This stability is necessary for the pump to operate efficiently, drawing coolant from the reservoir and circulating it through the engine’s cooling passages. The secure attachment afforded by the Connection Bracket reduces the risk of pump misalignment, which could lead to inefficient coolant circulation and potential engine damage.

Furthermore, the Connection Bracket contributes to the durability of the water pump itself. By offering a robust mounting point, it helps distribute the mechanical stresses experienced during engine operation. This distribution is key to prolonging the lifespan of the water pump and ensuring reliable performance over time.

Conclusion

In summary, the part 4007216 Connection Bracket is a fundamental component in the engine’s cooling system. Its role in securing the water pump, supporting coolant hoses, and providing a stable foundation for the pump arrangement underscores its importance in maintaining engine efficiency and longevity.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.