This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

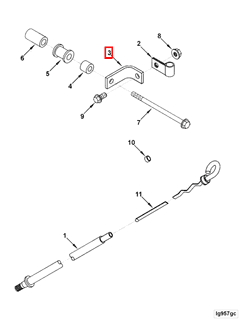

The 3864013 Connection Bracket is a component manufactured by Cummins, a well-established name in the commercial truck industry. This bracket is designed for use in commercial trucks, where it plays a role in facilitating connections between various components. Its application is integral to the operational efficiency and structural integrity of the truck 1.

Purpose of the Connection Bracket

This Cummins part serves a specific function within the truck’s system by providing a secure and stable connection point for different components. It ensures that these components are properly aligned and supported, which is vital for the truck’s overall performance. The bracket contributes to maintaining the structural integrity of the truck by securing components in place, thereby reducing the risk of mechanical failure due to vibrations or movement 2.

Key Features

The 3864013 is characterized by its robust design and material composition. It is constructed from high-quality materials that offer durability and resistance to corrosion, ensuring longevity even in harsh operating conditions. The bracket is designed to be compatible with other Cummins components, facilitating seamless integration into the truck’s system. Its design also considers ease of installation and maintenance, which are crucial for operational efficiency 3.

Benefits

The advantages of using this part include enhanced reliability due to its sturdy construction and corrosion resistance. It simplifies the installation process, reducing downtime for maintenance or repairs. Additionally, the bracket contributes to the overall performance of the truck by ensuring that components are securely connected and properly aligned.

Installation Process

Installing the 3864013 involves several steps to ensure it is properly secured and aligned. It is important to follow manufacturer guidelines for torque specifications and alignment to prevent damage to the bracket or connected components. Careful attention should be paid to any potential challenges during installation, such as ensuring all mating surfaces are clean and free from debris.

Maintenance and Troubleshooting

Regular maintenance of the 3864013 is recommended to ensure its longevity and performance. This includes periodic inspections for signs of wear or corrosion and tightening any fasteners as necessary. Common issues that may arise include loosening of fasteners or corrosion, which can be addressed through routine checks and timely repairs.

Safety Considerations

When handling and installing the 3864013, it is important to observe safety guidelines to prevent injury or damage to the component. This includes using appropriate personal protective equipment and ensuring that the truck is properly supported during installation. The bracket plays a role in ensuring safe truck operations by providing a secure connection for critical components.

Cummins Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. With a history spanning over a century, Cummins has established a reputation for quality and innovation in the commercial truck industry. The company’s commitment to excellence is reflected in its wide range of products, including the 3864013, which is designed to meet the demanding requirements of commercial truck applications.

Cummins Connection Bracket 3864013 Compatibility

The Cummins Connection Bracket, part number 3864013, is designed to integrate seamlessly with a range of Cummins engines, ensuring robust and reliable performance. This bracket is a critical component in the engine assembly, providing necessary support and stability.

Engine Compatibility

- 4B3.9 and 6B5.9 Engines

The Connection Bracket 3864013 is specifically engineered to fit both the 4B3.9 and 6B5.9 engines. These engines are known for their durability and efficiency, making them suitable for a variety of applications, from industrial to agricultural use. The bracket’s design allows it to interface effectively with the unique structural components of these engines, ensuring a secure and stable connection.

- Grouping of Engines

While the 4B3.9 and 6B5.9 engines are distinct in their specifications and applications, the Connection Bracket 3864013 is versatile enough to accommodate both. This compatibility is crucial for maintenance and repair operations, as it allows technicians to use a single part for multiple engine types, streamlining inventory and reducing downtime.

Installation and Functionality

The installation of the Connection Bracket 3864013 is straightforward, thanks to its precise engineering. It is designed to bolt into place, ensuring that it maintains the integrity of the engine’s structure. The bracket’s material and construction are optimized to withstand the rigors of engine operation, providing long-lasting support and reliability.

Importance of Proper Fitment

Ensuring that the Connection Bracket 3864013 is correctly fitted is essential for the overall performance and longevity of the engine. A well-fitted bracket helps in maintaining the alignment and stability of engine components, preventing potential issues such as misalignment or excessive wear. This, in turn, contributes to the engine’s efficiency and operational lifespan.

The Connection Bracket, part number 3864013, serves as a vital interface within the engine system, facilitating the secure attachment of various components. Specifically, it plays a significant role in integrating the Oil Level Gauge and the Oil Level Sensor into the engine assembly.

When installing the Oil Level Gauge, the Connection Bracket ensures a stable and precise mounting point. This gauge is essential for monitoring the oil level within the engine, providing real-time data to the operator. The bracket’s design allows for easy alignment and attachment, ensuring that the gauge is accurately positioned for optimal reading.

Similarly, the Oil Level Sensor benefits from the Connection Bracket’s secure mounting capabilities. The sensor is responsible for detecting the oil level and transmitting this information to the engine’s control system. The bracket ensures that the sensor is firmly in place, reducing the risk of detachment or misalignment, which could lead to inaccurate readings.

Conclusion

In summary, the Connection Bracket, part 3864013, is instrumental in maintaining the integrity and functionality of the Oil Level Gauge and Oil Level Sensor within the engine system. Its robust design and precise fitting capabilities contribute to the overall reliability and performance of the engine.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.