3630167

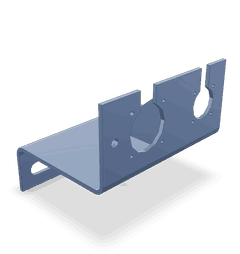

Connection Bracket

Cummins®

AVAILABLE

More than 10 are currently available

Ships within 2-4 business days

This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

The Cummins 3630167 Connection Bracket is a component designed for use in commercial trucks. It serves a specific function within the truck’s mechanical system, contributing to the overall operation and efficiency of the vehicle. Understanding its purpose and significance is important for maintaining and optimizing truck performance.

Basic Concepts of Connection Brackets

Connection brackets are mechanical components used to join or secure different parts of a system together. In the context of heavy-duty trucks, these brackets play a role in ensuring that various components are properly aligned and held in place. They contribute to the structural integrity and operational efficiency of the truck by facilitating the secure attachment of parts that need to work in unison 1.

Purpose of the 3630167 Connection Bracket

The 3630167 Connection Bracket is designed to secure and align specific components within a truck’s engine system. It ensures that parts are correctly positioned relative to each other, which is important for the efficient operation of the engine. This bracket helps maintain the structural integrity of the engine assembly by providing a stable connection point for various components 2.

Key Features

The 3630167 Connection Bracket is constructed from durable materials, ensuring it can withstand the rigors of heavy-duty truck operation. Its design includes features that enhance its performance, such as precise machining for accurate fitment and robust construction to endure high stress environments. Additionally, the bracket may incorporate design elements that facilitate easy installation and maintenance 3.

Benefits of Using the 3630167 Connection Bracket

Utilizing the 3630167 Connection Bracket offers several advantages. Its durable construction contributes to the longevity of the truck’s engine system. The design of the bracket allows for straightforward installation, reducing downtime during maintenance procedures. Furthermore, by ensuring components are securely and accurately aligned, the bracket plays a role in enhancing the overall reliability of the truck’s mechanical system.

Installation Process

Installing the 3630167 Connection Bracket involves several steps to ensure it is properly secured and aligned. The process may require specific tools and additional components, depending on the truck’s make and model. Following the manufacturer’s guidelines for installation is important to achieve the best results and ensure the bracket functions as intended within the engine system.

Maintenance and Troubleshooting

Regular maintenance of the 3630167 Connection Bracket is important to ensure its continued performance and the overall efficiency of the truck’s engine system. This may include periodic inspections for signs of wear or damage and ensuring all connections are secure. Troubleshooting common issues, such as misalignment or loose connections, can often be resolved by retightening fasteners or making minor adjustments to the bracket’s position.

Compatibility and Applications

The 3630167 Connection Bracket is designed for use with specific types of trucks and engine models. Its applications are tailored to meet the needs of these vehicles, ensuring compatibility and optimal performance. Understanding the bracket’s compatibility with different truck models is important for selecting the appropriate component for maintenance or upgrade purposes.

Safety Considerations

When installing or maintaining the 3630167 Connection Bracket, observing safety guidelines and precautions is important. This includes ensuring the truck is properly supported and the engine is cool before beginning work. Using the correct tools and following recommended procedures helps ensure safe operation and prevents accidents.

Cummins Overview

Cummins Inc. is a well-established manufacturer of diesel engines and related components for commercial vehicles. With a history of innovation and quality, Cummins has built a reputation for producing reliable and efficient engine systems. The company’s commitment to excellence is reflected in its wide range of products, including the 3630167 Connection Bracket, which is designed to meet the demanding requirements of heavy-duty truck applications.

Connection Bracket 3630167 by Cummins

The Connection Bracket part number 3630167, manufactured by Cummins, is a critical component in the assembly of certain engine models. This part is designed to provide a secure and stable connection between various engine components, ensuring the integrity and performance of the engine.

Compatibility with K38 and K50 Engines

The Connection Bracket 3630167 is specifically engineered to fit seamlessly with the K38 and K50 engine series. These engines, known for their robust design and reliability, benefit from the precision and durability of this bracket. The bracket’s design allows for efficient mounting and alignment, which is crucial for maintaining the operational efficiency of the engine.

Installation and Functionality

During the assembly process, the Connection Bracket 3630167 is positioned to connect key engine parts, ensuring they remain in the correct orientation and do not shift during operation. This is particularly important in high-stress environments where the engine is subjected to significant forces and vibrations. The bracket’s material and construction are chosen to withstand these conditions, providing a long-lasting solution that reduces the likelihood of mechanical failure.

Importance in Engine Performance

The proper installation of the Connection Bracket 3630167 is essential for the overall performance of the K38 and K50 engines. By maintaining the alignment and stability of connected components, the bracket helps to prevent wear and tear, ensuring that the engine operates smoothly and efficiently. This, in turn, contributes to the longevity and reliability of the engine, making it a preferred choice for various industrial and commercial applications.

Role of Part 3630167 Connection Bracket in Engine Systems

The part 3630167 Connection Bracket is integral to the secure and efficient integration of various components within engine systems. It serves as a foundational element for the Connector Mounting Bracket, ensuring that electrical connections are held firmly in place, reducing the risk of disconnection or damage during engine operation.

When paired with the Harness Mounting Kit, the Connection Bracket facilitates the organized routing and secure attachment of wiring harnesses. This is particularly important for the AEM Harness and other complex wiring systems, where precise placement and protection of wires are essential for optimal engine performance and reliability.

In the context of Cense Upfit and Engine Monitor systems, the Connection Bracket plays a key role in mounting these components. It provides a stable platform for these monitors, allowing them to accurately gauge engine parameters without interference from vibrations or movement.

Furthermore, the bracket is compatible with the Wiring Harness Mounting Kit, enhancing the overall structural integrity of the engine’s electrical system. This compatibility ensures that all wiring is not only securely mounted but also neatly organized, which is vital for maintaining a clean and accessible engine compartment.

The Connection Bracket also supports the Mounting Kit by offering additional points of attachment for various engine components. This versatility makes it a valuable asset in custom engine builds or modifications, where space and component arrangement are key considerations.

Conclusion

In summary, the part 3630167 Connection Bracket is a versatile and essential component in the assembly and maintenance of engine systems, providing the necessary support and organization for a wide range of electrical and monitoring components.

-

Hilgers, Michael. Alternative Powertrains and Extensions to the Conventional Powertrain. Springer Nature, 2023.

↩ -

Zhan, Quansheng, Eben, Shengbo, and Deng, Li Kun. Automotive Heating Ventilation and Air Conditioning. Jones Bartlett Learning, 2018.

↩ -

Isermann, Rolf. Combustion Engine Diagnosis. Springer Vieweg, 2017.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.