3411869

Connection Retainer

Cummins®

DISCONTINUED

2 are currently available

Ships within 2-4 business days

This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

The Connection Retainer 3411869, manufactured by Cummins, is a component designed to enhance the reliability and efficiency of commercial truck operations. Cummins, a well-established name in the automotive industry, produces a range of components that contribute to the performance and durability of commercial vehicles. This Cummins part plays a role in maintaining secure connections within a truck’s system.

Basic Concepts of Connection Retainers

A connection retainer is a device used in automotive systems to secure and maintain the integrity of connections between various components. Its general function is to prevent disconnections that could lead to system failures or inefficiencies. In the context of a truck’s components, connection retainers ensure that all parts remain securely attached, facilitating smooth operation and reducing the risk of malfunctions due to loose connections 1.

Purpose of the 3411869 Connection Retainer

This part is specifically designed to play a role in the operation of a truck by securing connections within the truck’s system. Its function is to ensure that all connections remain stable and secure, which is important for the overall reliability of the truck’s operations. Secure connections contribute to the efficient transfer of power, fluids, or signals between components, thereby enhancing the truck’s performance and safety 2.

Key Features

The 3411869 boasts several key features that enhance its performance and durability. It is constructed from high-quality materials that offer resistance to wear and corrosion, ensuring longevity in demanding commercial truck environments. The design of the retainer includes elements that allow for easy installation and adjustment, while also providing a strong grip on connections. Additionally, any unique attributes, such as specialized coatings or ergonomic designs, further contribute to its effectiveness in securing connections.

Benefits

The advantages provided by the 3411869 include improved reliability of connections, which can lead to increased safety and efficiency in truck operations. By ensuring that connections remain secure, the retainer helps prevent unexpected disconnections that could cause system failures or accidents. Furthermore, the enhanced reliability of connections can contribute to more consistent performance and reduced maintenance needs, offering long-term benefits to truck operators 3.

Installation Process

Proper installation of the 3411869 involves a series of steps to ensure correct fitting and function. The process begins with identifying the connection points that require a retainer. Next, the appropriate size of the retainer is selected to match the connection. Using the necessary tools, the retainer is then positioned over the connection and secured in place. It is important to follow best practices during installation, such as ensuring the retainer is not overtightened, to avoid damaging the connection or the retainer itself.

Troubleshooting Common Issues

Common problems associated with connection retainers can include loose connections, damage to the retainer, or failure to secure the connection properly. Potential causes for these issues may range from incorrect installation to wear and tear over time. Recommended troubleshooting steps include inspecting the retainer and connection for signs of damage or wear, ensuring the retainer is correctly installed, and replacing the retainer if necessary to restore secure connections.

Maintenance Tips

Regular maintenance practices for the 3411869 are important to ensure longevity and optimal performance. Inspection routines should include checking for signs of wear, corrosion, or damage to the retainer and the connections it secures. It is also advisable to periodically review the tightness of the retainer to ensure it remains secure. When considering replacement, factors such as the age of the retainer, the condition of the connections, and any signs of failure should be taken into account.

Cummins: Manufacturer Overview

Cummins is a renowned manufacturer in the automotive industry, with a history of producing high-quality components for commercial trucks. The company’s reputation is built on a commitment to innovation, reliability, and performance. Cummins offers a wide range of products designed to enhance the efficiency, safety, and durability of commercial vehicles, making them a trusted choice among truck operators and manufacturers alike.

Connection Retainer 3411869 in Cummins Engines

The Connection Retainer part number 3411869, manufactured by Cummins, is a crucial component in ensuring the proper functionality of various engine systems. This part is designed to fit seamlessly into the N14 CELECT and N14 MECHANICAL engines, playing a pivotal role in maintaining the integrity of the engine’s connections.

In the N14 CELECT engine, the Connection Retainer 3411869 is integral to the engine’s electronic control system. It ensures that the electrical connections remain secure and stable, which is essential for the engine’s performance and longevity. The CELECT system relies on precise and reliable connections to manage various engine functions, and this retainer helps in achieving that precision.

Similarly, in the N14 MECHANICAL engine, the Connection Retainer 3411869 is vital for maintaining the mechanical connections within the engine. This engine variant, while lacking the electronic control system, still requires robust and reliable connections to ensure smooth operation. The retainer helps in securing these connections, preventing any potential failures that could lead to downtime or performance issues.

Both engines benefit from the use of this part, as it provides a consistent and reliable method of securing connections, ensuring that the engine operates at peak efficiency. The design and material of the Connection Retainer 3411869 are tailored to withstand the rigors of engine operation, providing long-lasting durability and performance.

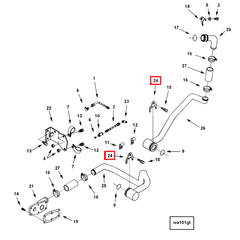

Role of Part 3411869 Connection Retainer in Plumbing and Aftercooler Water Systems

In the context of engine systems, the part 3411869 Connection Retainer is instrumental in ensuring the integrity and efficiency of both plumbing and aftercooler water components.

Plumbing Systems

Within plumbing systems, the Connection Retainer secures various joints and connections, preventing leaks and ensuring a consistent flow of fluids. It plays a significant role in maintaining the structural stability of pipes and fittings, which is essential for the reliable operation of the engine. By securing connections, it helps to mitigate the risk of fluid loss, which can lead to system inefficiencies and potential damage to other components.

Aftercooler Water Systems

In aftercooler water systems, the Connection Retainer is equally important. It ensures that the connections between the aftercooler and the water supply lines remain tight and secure. This is vital for the effective cooling of compressed air, which enhances the overall performance and longevity of the engine. Proper sealing provided by the Connection Retainer prevents water leaks, which could otherwise lead to inefficient cooling and increased wear on engine components.

Overall, the part 3411869 Connection Retainer is a key component in maintaining the operational efficiency and reliability of both plumbing and aftercooler water systems within engine configurations.

Conclusion

The 3411869 Connection Retainer by Cummins is a vital component in the maintenance and operation of commercial truck engines, particularly within the N14 CELECT and N14 MECHANICAL engine systems. Its role in securing connections within plumbing and aftercooler water systems underscores its importance in ensuring the efficiency, reliability, and longevity of engine operations. Proper installation, regular maintenance, and timely troubleshooting are essential practices to maximize the benefits of this Cummins part, contributing to the overall performance and safety of commercial vehicles.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.