This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

The Cummins 3410504 Connection Bracket is a component designed for use in commercial trucks. It serves a specific role within the truck’s system, contributing to the overall functionality and efficiency of the vehicle. Understanding its purpose and significance is key to maintaining and optimizing the performance of commercial trucks.

Purpose and Function

The 3410504 Connection Bracket plays a role in the truck’s system by securely connecting various components, ensuring they operate in unison. It facilitates the integration of different parts within the engine assembly, contributing to the smooth operation of the truck. By providing a stable connection point, it helps in the efficient transfer of forces and movements between components 1.

Key Features

The Cummins 3410504 Connection Bracket is characterized by its robust design and the materials used in its construction. Typically made from high-strength steel, it is engineered to withstand the rigors of commercial truck operations. Its design includes precise fitting points and mounting surfaces, ensuring a secure and reliable connection. Additionally, the bracket may feature corrosion-resistant coatings, enhancing its durability in various operating environments 2.

Benefits

The use of the 3410504 Connection Bracket offers several advantages. It contributes to improved efficiency by ensuring that components are securely connected, reducing the risk of misalignment or failure. Its durable construction enhances the longevity of the truck’s engine system, providing reliable performance over time. Furthermore, the bracket’s design can lead to easier maintenance and repair processes, minimizing downtime for commercial operations 3.

Installation Process

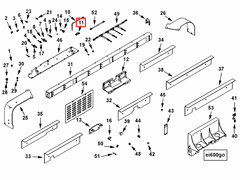

Installing the 3410504 Connection Bracket requires careful attention to detail. The process involves securing the bracket to the designated points within the engine assembly using the appropriate fasteners. It is important to use the correct tools and follow the manufacturer’s guidelines to ensure a proper fit. Careful alignment and torque specifications should be observed to maintain the integrity of the connection 4.

Maintenance Tips

To ensure the longevity and optimal performance of the 3410504 Connection Bracket, regular maintenance is recommended. This includes inspecting the bracket for signs of wear or damage, ensuring that all fasteners are secure, and cleaning the area around the bracket to prevent the accumulation of debris. Applying a protective coating can also help in maintaining its condition, especially in corrosive environments 5.

Troubleshooting Common Issues

Common issues with the 3410504 Connection Bracket may include loosening of fasteners, corrosion, or physical damage. Addressing these problems promptly is important to prevent further complications. Solutions may involve re-tightening fasteners, applying anti-corrosive treatments, or replacing the bracket if it is damaged beyond repair. Regular inspections can help in identifying and resolving these issues early 6.

Safety Considerations

When working with the 3410504 Connection Bracket, it is important to observe safety guidelines to prevent accidents. This includes ensuring that the truck is properly secured and the engine is off before beginning any work. Using the correct tools and following safety protocols can help in maintaining a safe working environment. Additionally, being aware of the bracket’s location and the components it connects can aid in avoiding accidental damage during maintenance or repair tasks 7.

Cummins Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. With a history of innovation and quality, Cummins serves commercial truck, bus, construction, agricultural, and power generation markets. The company is known for its commitment to reliability, efficiency, and sustainability in the products it offers.

Connection Bracket 3410504 in Cummins Engines

The Connection Bracket 3410504 is a component in the Cummins QSK45 CM500 and QSK60 CM500 engines. This part is designed to ensure proper alignment and secure mounting of various engine components, contributing to the overall stability and efficiency of the engine.

In the Cummins QSK45 CM500 and QSK60 CM500 engines, the Connection Bracket 3410504 is strategically positioned to connect different parts of the engine. Its role is to maintain the integrity of the engine’s structure by providing a stable link between specified components. This bracket is integral to the engine’s operational integrity, ensuring that the connected parts remain in their intended positions under various operational conditions.

The design of the Connection Bracket 3410504 is tailored to withstand the rigors of engine operation, including high temperatures, vibrations, and mechanical stresses. This ensures that the bracket performs reliably over the engine’s lifespan, contributing to the engine’s durability and performance.

For maintenance and repair purposes, the Connection Bracket 3410504 is engineered to be easily accessible. This facilitates efficient servicing and replacement, minimizing downtime and ensuring that the engine can be maintained with minimal disruption. The bracket’s design also allows for precise alignment during reassembly, which is crucial for maintaining the engine’s performance and longevity.

Role of Part 3410504 Connection Bracket in Engine Systems

The part 3410504 Connection Bracket is instrumental in integrating various components within engine systems. It serves as a pivotal junction point, facilitating the secure attachment of accessories to the engine. This bracket ensures that accessories are properly aligned and supported, which is essential for their optimal performance and durability.

In electrical systems, the Connection Bracket plays a significant role by providing a stable platform for mounting electrical components. This stability is vital for maintaining consistent electrical connections, which are necessary for the reliable operation of engine-related electronics.

For instruments, the bracket offers a robust mounting solution that ensures instruments are securely fixed in place. This is particularly important for instruments that require precise positioning to deliver accurate readings, such as engine monitors.

When it comes to engine mounting, the Connection Bracket helps in distributing the load evenly across the engine structure. This even distribution is key to preventing undue stress on any single point, thereby enhancing the overall structural integrity of the engine system.

Conclusion

In summary, the Connection Bracket 3410504 is a vital component in the Cummins QSK45 CM500 and QSK60 CM500 engines, providing essential support and stability to the engine’s structure. Its robust design and strategic placement ensure that the engine operates efficiently and reliably. The bracket’s role in integrating various engine system components, enhancing functionality, and ensuring reliable performance underscores its importance in maintaining the overall efficiency and durability of commercial trucks.

-

Martyr, A.J. Engine Testing: Theory and Practice: Third Edition. SAE International, 2007.

↩ -

Nunney, MJ. Light and Heavy Vehicle Technology, Fourth Edition. Butterworth-Heinemann, 2007.

↩ -

Crolla, David. Crolla Encyclopedia. Wiley, 2015.

↩ -

Hilgers, Michael. Alternative Powertrains and Extensions to the Conventional Powertrain. Springer Nature, 2023.

↩ -

Martyr, A.J. Engine Testing: Theory and Practice: Third Edition. SAE International, 2007.

↩ -

Nunney, MJ. Light and Heavy Vehicle Technology, Fourth Edition. Butterworth-Heinemann, 2007.

↩ -

Crolla, David. Crolla Encyclopedia. Wiley, 2015.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.