This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

The Cummins 3252277 Connection Gasket is a component designed for use in commercial trucks, specifically within the L10 MECHANICAL engine series. This part plays a crucial role in ensuring the secure and leak-proof seal between various engine components, contributing to the overall efficiency and reliability of the vehicle.

Basic Concepts of Connection Gaskets

Connection gaskets are sealing elements used in mechanical assemblies to prevent leaks between mating surfaces. They operate by filling the irregularities between surfaces, creating a seal that prevents the escape of fluids or gases. In the context of commercial trucks, these gaskets are vital for maintaining the integrity of various systems, ensuring that fluids and gases remain contained within their designated pathways 1.

Purpose of the Cummins 3252277 Connection Gasket

The Cummins 3252277 Connection Gasket is positioned within the truck’s engine or other systems where sealing is required. Its role is to provide a reliable seal between components, preventing leaks that could lead to system failure or inefficiency. The gasket’s placement is critical, as it ensures that the connection between parts remains secure under operating conditions 2.

Key Features

The Cummins 3252277 Connection Gasket is characterized by its material composition and design elements. It is made from materials that offer durability and resistance to the harsh conditions found in commercial truck engines. The design of the gasket includes features that enhance its sealing capabilities, such as specific shapes and textures that improve contact with mating surfaces 3.

Benefits

Utilizing the Cummins 3252277 Connection Gasket offers several advantages. It provides improved sealing efficiency, which contributes to the overall performance of the truck’s systems. The gasket’s durability ensures long-term reliability, even in demanding operating environments. Additionally, its design enhances the gasket’s ability to withstand pressure and temperature fluctuations, further contributing to the truck’s operational reliability 4.

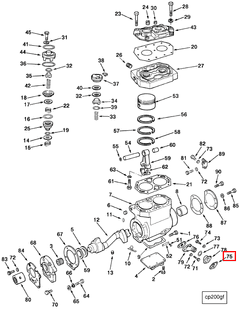

Installation Process

Installing the Cummins 3252277 Connection Gasket requires attention to detail to ensure a secure fit. Preparatory steps include cleaning the mating surfaces to remove any debris that could compromise the seal. The installation process involves positioning the gasket correctly between the components and ensuring it is not damaged during assembly. Tools required may include gasket scrapers and torque wrenches to achieve the proper tightening specifications.

Troubleshooting Common Issues

Common issues with connection gaskets, such as leaks or failures, can often be traced to installation errors or material degradation. Troubleshooting these problems involves inspecting the gasket and mating surfaces for signs of wear or damage. Addressing these issues may require replacing the gasket or adjusting the components to ensure a proper seal is achieved.

Maintenance Tips

Regular maintenance of the Cummins 3252277 Connection Gasket is important for ensuring its continued performance. Inspection intervals should be established based on the truck’s operating conditions, with more frequent checks for vehicles in harsh environments. Cleaning procedures should be followed to remove any contaminants that could affect the gasket’s sealing ability. Replacement should be considered if the gasket shows signs of wear or if leaks are detected.

Manufacturer Overview - Cummins

Cummins Inc. is a leading manufacturer in the commercial truck industry, known for its wide range of high-quality components. The company’s history of innovation and commitment to excellence has established it as a trusted name in the industry. Cummins components, including the 3252277 Connection Gasket, are designed with precision and reliability in mind, reflecting the company’s dedication to enhancing the performance and durability of commercial trucks.

Role of Part 3252277 Connection Gasket in Engine Systems

The part 3252277 Connection Gasket is integral to the efficient operation of various engine systems, particularly in ensuring the secure and leak-free transfer of fluids and gases.

Compressor Systems

In compressor systems, the Connection Gasket ensures a tight seal between the compressor housing and the connecting pipes. This seal is essential for maintaining the pressure integrity of the compressed air or gas. Without a reliable seal, pressure loss can occur, leading to reduced efficiency and potential system failures. The gasket’s role here is to prevent any leakage, ensuring that the compressor operates within its designed parameters.

Air Transfer Connections

For air transfer connections, the Connection Gasket plays a significant role in sealing the joints between different sections of the air intake and exhaust systems. This is particularly important in turbocharged engines where the air pressure is significantly higher than in naturally aspirated engines. The gasket ensures that the pressurized air is directed efficiently through the system, without any loss, which is vital for maintaining engine performance and responsiveness.

Oil Transfer Connections

In oil transfer connections, the Connection Gasket is used to seal the joints in the oil passages and filters. This is essential for maintaining the lubrication system’s integrity, ensuring that oil is delivered to all moving parts without leaks. The gasket helps in preventing oil contamination and ensures that the oil pressure remains consistent, which is vital for the longevity and performance of the engine components.

Conclusion

The Cummins 3252277 Connection Gasket is a vital component for the L10 MECHANICAL engines, providing essential sealing between various engine components and ensuring the engine operates efficiently and reliably. Its role in compressor systems, air transfer connections, and oil transfer connections underscores its importance in maintaining the engine’s performance and durability.

-

Dixon, John. Modern Diesel Technology: Heating, Ventilation, Air Conditioning, Refrigeration, 2nd Edition. Cengage Learning, 2014.

↩ -

Bartz, Wilfried J. Engine Oils and Automotive Lubrication Mechanical Engineering Book 80. CRC Press, 2019.

↩ -

Robinson, Alan and Livesey, Andrew. The Repair of Vehicle Bodies Fifth Edition. Elsevier, 2006.

↩ -

Han, Zhiyu. Simulation and Optimization of Internal Combustion Engines. SAE International, 2022.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.