This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

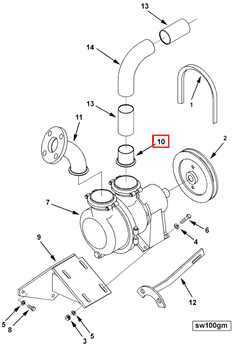

The Sea Water Connection 3060820 is a specialized component manufactured by Cummins, a prominent entity in the automotive and industrial sectors. This part is designed for use in commercial trucks, particularly those operating in marine or industrial environments where sea water is utilized for cooling purposes. Cummins is renowned for its high-quality engine components, and the Sea Water Connection 3060820 is no exception, offering reliable performance and durability in demanding applications 1.

Purpose and Function

The Sea Water Connection 3060820 facilitates the flow of sea water in the truck’s cooling system, which is used to cool the engine and other components. In marine or industrial settings, sea water serves as a readily available and effective cooling medium. The connection ensures a secure and efficient transfer of sea water to the cooling system, helping to maintain optimal operating temperatures and prevent overheating 2.

Key Features

The Sea Water Connection 3060820 is characterized by several key features that enhance its performance and durability. Its design is engineered to withstand the corrosive nature of sea water, ensuring long-term reliability. The component is constructed from high-quality materials that resist corrosion and wear, contributing to its robustness. Additionally, the connection is designed for easy installation and maintenance, featuring a straightforward design that simplifies the replacement process.

Benefits

The use of the Sea Water Connection 3060820 offers several benefits. It contributes to improved cooling efficiency by ensuring a consistent and reliable flow of sea water to the cooling system. Its robust construction enhances reliability, even in harsh environments where exposure to sea water and other corrosive elements is common. Furthermore, the design of the connection allows for ease of installation and maintenance, reducing downtime and facilitating quick repairs when necessary.

Installation Process

Installing the Sea Water Connection 3060820 requires careful attention to detail to ensure proper function and longevity. The process involves several steps:

- Ensure the truck’s engine is turned off and cooled down to prevent burns or injuries.

- Locate the existing sea water connection and disconnect any hoses or fittings attached to it.

- Remove the old connection, taking care not to damage surrounding components.

- Install the new Sea Water Connection 3060820, ensuring it is securely fastened and aligned correctly.

- Reattach any hoses or fittings, ensuring all connections are tight and secure.

- Test the connection for leaks by running the engine and observing the sea water flow.

Maintenance Tips

To ensure the optimal performance and longevity of the Sea Water Connection 3060820, regular maintenance is recommended. This includes:

- Inspecting the connection for signs of corrosion, wear, or damage at regular intervals.

- Cleaning the connection and surrounding areas to remove any buildup of salt or debris that could affect performance.

- Ensuring all hoses and fittings are securely attached and free from leaks.

- Replacing the connection if significant corrosion or damage is detected, to prevent potential failures.

Troubleshooting Common Issues

Common issues with the Sea Water Connection 3060820 may include leaks, corrosion, or blockages. To address these problems:

- Check for leaks by inspecting the connection and surrounding hoses for signs of sea water leakage. Tighten any loose connections or replace damaged hoses as necessary.

- Address corrosion by cleaning the connection thoroughly and applying a corrosion-resistant coating if needed. Replace the connection if corrosion is severe.

- Clear blockages by disconnecting the hoses and flushing the connection with clean water to remove any debris or buildup.

Safety Considerations

When working with the Sea Water Connection 3060820, it is important to observe several safety considerations:

- Ensure the engine is turned off and cooled down before beginning any work to avoid burns or injuries.

- Wear appropriate personal protective equipment, including gloves and safety glasses, to protect against splashes of sea water and potential debris.

- Handle the connection with care to avoid damage, and store it in a dry, corrosion-resistant environment when not in use.

- Dispose of any old or damaged connections in accordance with local regulations to prevent environmental harm.

Cummins Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. With a history spanning over a century, Cummins has established a reputation for innovation, quality, and reliability in the automotive and industrial sectors. The company offers a wide range of products and services, including engines, powertrains, and aftermarket parts, designed to meet the needs of customers in various industries. Cummins is committed to sustainability and efficiency, continually striving to improve the performance and environmental impact of its products 3.

Role of Part 3060820 Sea Water Connection in Engine Systems

The Sea Water Connection 3060820 is an essential component in marine engine systems, facilitating the interaction between the engine and the surrounding marine environment. This component is integral to the operation of several key systems, including the pump and raw water systems.

Integration with the Pump System

In marine engines, the pump system is responsible for circulating coolant and other fluids to maintain optimal engine temperature and performance. The Sea Water Connection plays a significant role here by providing a direct interface for seawater to enter the pump system. This allows for efficient heat exchange, where the pump draws in seawater to cool the engine components, such as the cylinder heads and exhaust manifolds. The Sea Water Connection ensures a consistent and reliable flow of seawater into the pump, which is vital for the pump’s effectiveness in dissipating heat.

Function in the Raw Water System

The raw water system in marine engines is designed to use seawater for cooling purposes without mixing it with the engine’s freshwater coolant. The Sea Water Connection is a pivotal part of this system, acting as the initial point of contact for seawater. It allows seawater to be drawn into the raw water system, where it passes through various heat exchangers and cooling passages. This process helps in maintaining the engine’s temperature within safe operating limits. The connection ensures that the raw water system operates efficiently, preventing overheating and potential engine damage.

Overall Impact on Engine Performance

By seamlessly integrating with both the pump and raw water systems, the Sea Water Connection enhances the overall performance and reliability of marine engines. It ensures that the engine remains cool under varying operational conditions, contributing to prolonged engine life and consistent performance. The component’s design and placement are optimized to handle the corrosive nature of seawater, providing a durable and effective solution for marine cooling needs.

Conclusion

The Sea Water Connection 3060820 by Cummins is a critical component for marine and industrial engine cooling systems. Its robust design, ease of installation, and maintenance features make it a reliable choice for ensuring efficient cooling and engine performance in harsh environments. Regular maintenance and proper installation are key to maximizing the benefits of this Cummins part.

-

Schneider, W.-H. (2016). Pistons and Engine Testing. Springer Nature.

↩ -

Awari, G.K., Kumbhar, V.S., & Tirpude, R.B. (2011). Automotive Systems Principles and Practice. CRC Press.

↩ -

Cummins Inc. Company Overview. Retrieved from Cummins Official Website.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.