3031708

Connection Gasket

Cummins®

AVAILABLE

2 are currently available

Ships within 2-4 business days

This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

The Cummins 3031708 Connecting Gasket is a component designed for use in heavy-duty truck engines. Its purpose is to ensure a secure seal between various engine components, contributing to the overall efficiency and reliability of the engine. This gasket plays a significant role in maintaining the integrity of the engine’s internal environment by preventing leaks and ensuring proper pressure maintenance 1.

Basic Concepts of Connecting Gaskets

Connecting gaskets are specialized seals used in engine assemblies to create a tight barrier between mating surfaces. Their general function is to prevent the escape of fluids and gases, ensuring that the engine operates within its designed parameters. By filling the microscopic gaps between surfaces, connecting gaskets contribute to the sealing process, which is vital for the engine’s performance and longevity 2.

Purpose of the 3031708 Connecting Gasket

The 3031708 Connecting Gasket is specifically designed to play a role in the operation of truck engines by sealing the connection points between engine components. Its position within the engine assembly is critical, as it helps maintain the pressure and fluid integrity necessary for efficient engine function. This gasket ensures that the engine components work in unison without the risk of leaks, which could lead to decreased performance or engine damage 3.

Key Features

The 3031708 Connecting Gasket boasts several key features that enhance its performance and durability. It is composed of materials that are resistant to high temperatures and pressures, ensuring longevity under demanding conditions. The design specifications of this gasket include precise dimensions and a robust construction that allows it to withstand the rigors of heavy-duty engine operation. Additionally, any unique attributes, such as reinforced edges or specialized coatings, further contribute to its effectiveness in sealing applications 4.

Benefits

The use of the 3031708 Connecting Gasket provides several benefits to engine operation. It contributes to improved engine efficiency by ensuring that all components operate within their intended parameters. The enhanced sealing capabilities of this gasket help maintain the engine’s internal pressure and prevent leaks, which can lead to a more reliable and longer-lasting engine. Overall, the gasket’s design and material composition play a role in supporting the engine’s performance and durability 5.

Installation Process

Proper installation of the 3031708 Connecting Gasket is important for ensuring a secure fit and optimal engine performance. The process involves several steps, including cleaning the mating surfaces to remove any debris or old gasket material. Tools required for installation may include a gasket scraper, a torque wrench, and possibly a gasket sealant, depending on the manufacturer’s recommendations. Best practices for installation include ensuring the gasket is properly aligned and not over-tightened, which could lead to damage 6.

Troubleshooting Common Issues

Common problems associated with connecting gaskets, such as leaks or failures, can often be traced back to installation errors or material degradation over time. Troubleshooting these issues involves a systematic approach to identifying the source of the problem. This may include inspecting the gasket for signs of wear or damage, checking the mating surfaces for proper alignment and cleanliness, and ensuring that the installation torque specifications were followed 7.

Maintenance Tips

Regular maintenance of the 3031708 Connecting Gasket is important for ensuring its continued effectiveness. Inspection intervals should be established based on the engine’s operating conditions and manufacturer recommendations. Cleaning procedures may involve gently wiping the gasket and mating surfaces to remove any buildup without damaging the gasket material. Replacement should be considered if the gasket shows signs of wear, deformation, or if leaks are detected during routine inspections 8.

Cummins Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. With a history spanning over a century, Cummins has established a reputation for quality and innovation in the automotive industry, particularly in the manufacture of diesel engines and components. The company’s product range includes a variety of engines and parts designed for heavy-duty applications, reflecting its commitment to meeting the needs of its customers with reliable and efficient power solutions.

Cummins Connecting Gasket 3031708 in Engine Applications

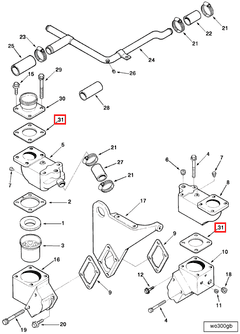

The Cummins Connecting Gasket part number 3031708 is a critical component in ensuring the integrity and performance of various engine systems. This gasket is specifically designed to fit seamlessly with the V903 engine, providing a reliable seal between the engine’s connecting components.

In the V903 engine, the connecting gasket 3031708 is essential for maintaining the separation between different engine sections, preventing leaks and ensuring that the engine operates efficiently. Its placement and design are critical for the engine’s overall functionality, as it must withstand high pressures and temperatures inherent in engine operations.

The gasket’s material and construction are tailored to meet the stringent demands of the V903 engine, ensuring durability and longevity. This part is integral to the engine’s assembly, and its proper installation is crucial for the engine’s performance and reliability.

Role of Part 3031708 Connecting Gasket in Engine Systems

The part 3031708 Connecting Gasket is an essential component in ensuring the integrity and efficiency of various engine systems. Its primary function is to create a reliable seal between different engine components, preventing leaks and maintaining system pressure. Here’s how it integrates with specific components:

Water Outlet Connection

In the water outlet connection, the 3031708 Connecting Gasket ensures a tight seal between the water outlet and the engine block or cylinder head. This seal is vital for maintaining the coolant flow, which is necessary for regulating engine temperature. Without a proper seal, coolant leaks can occur, leading to inefficient cooling and potential engine overheating.

Water Outlet

At the water outlet, the gasket plays a significant role in sealing the connection points where the coolant exits the engine. This prevents coolant from escaping and ensures that the cooling system operates under the correct pressure, which is essential for optimal engine performance and longevity.

Water Outlet Conn.

For the water outlet connection (conn.), the 3031708 Connecting Gasket is used to seal the interface between the water outlet and other components such as hoses or additional cooling system parts. This ensures that the coolant pathway remains intact, facilitating consistent and effective heat dissipation from the engine.

Water Outlet Connection

In the broader context of the water outlet connection, the gasket is instrumental in sealing various junctions within the cooling system. This includes connections to the thermostat housing, radiator hoses, and other ancillary components. By maintaining these seals, the gasket helps in preserving the overall efficiency of the engine’s cooling system, thereby contributing to the engine’s reliable operation.

Conclusion

The Cummins 3031708 Connecting Gasket is a vital component in heavy-duty truck engines, ensuring the integrity and efficiency of engine systems by providing reliable seals between components. Its proper installation, maintenance, and understanding of its role in engine operations are crucial for maintaining engine performance and reliability.

-

Boyce, M. P. (2011). Gas Turbine Engineering Handbook (4th ed.). Butterworth-Heinemann.

↩ -

Reif, K. (2015). Automotive Mechatronics. Springer Vieweg.

↩ -

Duffy, O. C., & Wright, G. (2016). Fundamentals of Medium-Heavy Duty Commercial Vehicle Systems. Jones Bartlett Learning.

↩ -

Harrison, M. (2004). Controlling Noise and Vibration in Road Vehicles. SAE International.

↩ -

Cummins Inc. (n.d.). Owners Manual for L9N CM2380 L142B. Bulletin Number 5660009.

↩ -

Cummins Inc. (n.d.). Owners Manual for L9N CM2380 L142B. Bulletin Number 5660009.

↩ -

Cummins Inc. (n.d.). Owners Manual for L9N CM2380 L142B. Bulletin Number 5660009.

↩ -

Cummins Inc. (n.d.). Owners Manual for L9N CM2380 L142B. Bulletin Number 5660009.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.