This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

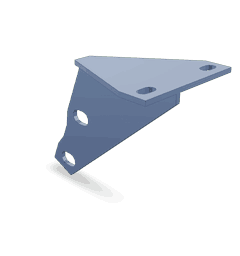

The Connection Brace 3029037, manufactured by Cummins, is a component designed to enhance the structural integrity and operational efficiency of commercial trucks. Cummins, a well-established name in the automotive industry, produces this brace to ensure that trucks maintain their structural stability under various operational conditions.

Basic Concepts of Connection Braces

A connection brace is a structural component used in vehicle frameworks to reinforce and stabilize the chassis. It plays a role in distributing loads evenly across the vehicle’s frame, thereby contributing to the overall durability and performance of the truck. By securing different parts of the chassis together, connection braces help in maintaining the alignment and integrity of the truck’s structure 1.

Purpose of the 3029037 Connection Brace

The 3029037 Connection Brace is specifically engineered to support various components within the truck’s structure. It plays a role in reinforcing the chassis, ensuring that the truck can withstand the stresses and strains encountered during operation. This brace contributes to the truck’s structural stability by providing additional support to critical areas, thereby enhancing the overall performance and longevity of the vehicle 2.

Key Features

The 3029037 Connection Brace is constructed from high-strength materials, ensuring durability and resistance to wear and tear. Its design incorporates precise engineering to fit seamlessly within the truck’s chassis, offering optimal support without compromising on space or weight. Unique characteristics of this brace include its corrosion-resistant coating, which enhances its longevity in various environmental conditions, and its ease of installation, which minimizes downtime during maintenance 3.

Benefits

Utilizing the 3029037 Connection Brace offers several advantages. Its robust construction contributes to improved durability, reducing the likelihood of structural failures. Enhanced safety is another benefit, as the brace helps maintain the truck’s structural integrity, which is vital for the safety of the vehicle’s occupants and cargo. Additionally, the brace can lead to potential cost savings over time due to reduced maintenance needs and extended component lifespan 4.

Installation Process

Proper installation of the 3029037 Connection Brace is vital for optimal performance. The process involves securing the brace to the designated points on the truck’s chassis using the appropriate fasteners. It is important to follow the manufacturer’s guidelines to ensure that the brace is installed correctly, which includes using the recommended tools and checking for proper alignment and tightness of all connections. Correct installation ensures that the brace effectively supports the truck’s structure 5.

Troubleshooting and Maintenance

Common issues with the 3029037 Connection Brace may include corrosion or loosening of fasteners. Regular inspections can help identify these problems early. Troubleshooting steps involve cleaning the brace and its mounting points, reapplying corrosion-resistant coatings if necessary, and tightening or replacing fasteners as needed. Maintenance tips include keeping the area around the brace clean and free of debris, and periodically checking for signs of wear or damage 6.

Compatibility and Applications

The 3029037 Connection Brace is designed for use in specific types of trucks and models. It is engineered to fit into various truck configurations, offering versatility across different applications. Its design allows it to be integrated into the truck’s structure without requiring significant modifications, making it a suitable choice for enhancing the structural integrity of compatible vehicles 7.

Safety Considerations

When working with the 3029037 Connection Brace, it is important to follow safety guidelines to ensure a safe working environment. This includes wearing appropriate personal protective equipment, ensuring that the truck is securely supported during installation or maintenance, and following all manufacturer-recommended safety procedures. Operational safety checks should be conducted regularly to ensure that the brace remains in good condition and is functioning as intended 8.

Cummins Overview

Cummins is a renowned manufacturer in the automotive industry, known for its commitment to quality and innovation. With a rich history of producing reliable and high-performance components, Cummins has established a strong reputation for excellence. Their dedication to advancing automotive technology is evident in their wide range of products, designed to meet the demanding requirements of commercial vehicles 9.

Cummins Connection Brace 3029037 in Engine Applications

The Cummins Connection Brace 3029037 is a critical component in the assembly of several Cummins engine models. This part is designed to provide structural integrity and stability to the engine by connecting various parts and ensuring they remain aligned during operation.

K38 and K50 Engines

In the K38 and K50 engine series, the Connection Brace 3029037 plays a pivotal role in maintaining the alignment and stability of the engine’s internal components. These engines are known for their robust design and are often used in heavy-duty applications where reliability and performance are paramount. The Connection Brace ensures that the engine’s parts remain securely fastened, reducing the risk of misalignment and potential damage.

The K38 engine, with its high torque output and durability, benefits significantly from the Connection Brace. This part helps in managing the stresses induced by the engine’s operation, ensuring that the engine can withstand the rigors of demanding environments. Similarly, the K50 engine, which is designed for both power and efficiency, relies on the Connection Brace to maintain its structural integrity, contributing to its overall performance and longevity.

By integrating the Connection Brace 3029037 into the design of these engines, Cummins ensures that both the K38 and K50 engines can operate smoothly and reliably, even under heavy loads and in challenging conditions. This part is a testament to Cummins’ commitment to quality and durability in their engine designs 10.

Role of Part 3029037 Connection Brace in Engine Systems

The Part 3029037 Connection Brace is instrumental in ensuring the structural integrity and efficient operation of various engine components. It plays a significant role in the following areas:

Water Inlet Connection

The Connection Brace is essential in maintaining the alignment and stability of the Water Inlet Connection. This component is responsible for directing coolant into the engine, ensuring optimal temperature regulation. The brace helps to secure the Water Inlet Connection, preventing any misalignment that could lead to leaks or inefficient coolant flow 11.

Water Inlet Connection Mounting

In the Water Inlet Connection Mounting system, the Connection Brace provides the necessary support to keep the mounting assembly firmly in place. This is particularly important during engine vibrations and operational stresses. The brace ensures that the mounting remains stable, which in turn maintains the integrity of the Water Inlet Connection and promotes consistent engine performance 12.

General Structural Support

Beyond specific components, the Connection Brace offers general structural support within the engine system. It helps to distribute stresses evenly across various points, reducing the likelihood of component failure due to mechanical stress. This support is vital for the longevity and reliability of the engine system as a whole 13.

Conclusion

In summary, the Part 3029037 Connection Brace is a key element in maintaining the structural integrity and operational efficiency of engine components, particularly in systems involving coolant flow and mounting assemblies. Its robust construction, ease of installation, and compatibility with various truck models make it an essential component for enhancing the durability and performance of commercial trucks.

-

Dixon, J. (2010). Modern Diesel Technology Preventive Maintenance and Inspection. Delmar Cengage Learning.

↩ -

Heywood, J. (2019). Internal Combustion Engine Fundamentals. McGraw-Hill Education.

↩ -

Crolla, D. (2015). Crolla Encyclopedia. Wiley.

↩ -

Hick, H., Kupper, K., & Sorger, H. (2021). Systems Engineering for Automotive Powertrain Development. Springer.

↩ -

Dixon, J. (2010). Modern Diesel Technology Preventive Maintenance and Inspection. Delmar Cengage Learning.

↩ -

Heywood, J. (2019). Internal Combustion Engine Fundamentals. McGraw-Hill Education.

↩ -

Crolla, D. (2015). Crolla Encyclopedia. Wiley.

↩ -

Hick, H., Kupper, K., & Sorger, H. (2021). Systems Engineering for Automotive Powertrain Development. Springer.

↩ -

Dixon, J. (2010). Modern Diesel Technology Preventive Maintenance and Inspection. Delmar Cengage Learning.

↩ -

Heywood, J. (2019). Internal Combustion Engine Fundamentals. McGraw-Hill Education.

↩ -

Crolla, D. (2015). Crolla Encyclopedia. Wiley.

↩ -

Hick, H., Kupper, K., & Sorger, H. (2021). Systems Engineering for Automotive Powertrain Development. Springer.

↩ -

Dixon, J. (2010). Modern Diesel Technology Preventive Maintenance and Inspection. Delmar Cengage Learning.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.