This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

The Sea Water Connection 3008816 is a specialized component designed by Cummins for use in heavy-duty trucks, particularly those operating in marine environments. This part is integral to the cooling system, facilitating the exchange of sea water to help regulate engine temperature and ensure optimal performance under demanding conditions.

Basic Concepts of Sea Water Connection

Sea water connections are fundamental to the cooling systems of marine engines. They allow sea water to be drawn into the engine’s cooling system, where it absorbs heat from the engine components before being expelled back into the sea. This process is vital for maintaining engine temperature within safe operating limits, preventing overheating, and ensuring the longevity of engine parts 1.

Purpose of Sea Water Connection 3008816

This Cummins part plays a specific role in the truck’s cooling system by enabling the efficient exchange of sea water. It is designed to connect the engine’s cooling system to a sea water source, allowing for the circulation of sea water through the engine’s heat exchanger. This facilitates effective heat dissipation, crucial for engines operating in high-temperature environments or under heavy loads.

Key Features

The Sea Water Connection 3008816 is constructed from high-quality materials that offer resistance to corrosion and wear, ensuring durability in harsh marine environments. Its design includes features that enhance the efficiency of sea water flow, such as smooth internal passages and precise fitting mechanisms. These attributes not only improve the cooling efficiency but also contribute to the overall reliability of the cooling system.

Benefits

Utilizing the Sea Water Connection 3008816 offers several advantages. It contributes to improved cooling efficiency, helping to maintain engine temperature within optimal ranges. Its robust construction ensures durability, even in corrosive marine environments, potentially leading to cost savings through extended component life. Additionally, its efficient design can reduce the risk of overheating, enhancing engine performance and reliability.

Installation Considerations

When installing the Sea Water Connection 3008816, it is important to follow guidelines to ensure a proper fit and integration with the existing cooling system components. Necessary tools include wrenches for securing connections and possibly a sealant to prevent leaks. Careful alignment and secure fastening are crucial to ensure the connection is watertight and functions as intended within the cooling system.

Troubleshooting Common Issues

Common issues with sea water connections include leaks and corrosion. To address these, regular inspections for signs of wear or damage are recommended. If a leak is detected, the connection should be resealed or replaced as necessary. Corrosion can often be mitigated through the use of compatible materials and regular maintenance, including cleaning and inspection.

Maintenance Tips

To prolong the lifespan of the Sea Water Connection 3008816, routine maintenance practices are advised. This includes regular inspections for signs of wear, corrosion, or leaks. Cleaning the connection and its surrounding components can prevent buildup that might impede sea water flow. When significant wear or damage is observed, considering replacement can help maintain the efficiency and reliability of the cooling system.

Cummins Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. With a history of innovation and a commitment to quality, Cummins has established itself as a trusted provider of reliable components for the automotive and heavy-duty truck industries. Their expertise in engine manufacturing and dedication to customer satisfaction underscore the quality and performance of their products, including the Sea Water Connection 3008816 2.

Sea Water Connection Part 3008816 in Cummins Engines

This Cummins part is an essential component in the marine engine ecosystem. It is integral to the cooling systems of various Cummins marine engines, ensuring efficient thermal management.

K38 Engine

In the K38 engine, this part plays a critical role in the cooling process. It facilitates the flow of seawater through the engine’s cooling system, which is vital for maintaining optimal operating temperatures. This connection ensures that the seawater is directed correctly, enhancing the engine’s overall performance and longevity.

K50 Engine

Similarly, for the K50 engine, the Sea Water Connection part 3008816 is indispensable. It connects the seawater intake to the engine’s cooling system, ensuring that the seawater flows through the necessary pathways. This connection is crucial for preventing overheating and ensuring that the engine operates within its designed thermal parameters.

Grouping of Engines

Both the K38 and K50 engines rely on the Sea Water Connection part 3008816 for effective thermal management. This part’s design and functionality are tailored to meet the specific needs of these engines, ensuring that they can operate efficiently in marine environments. The part’s robust construction and precise engineering make it a reliable choice for these applications.

Role of Part 3008816 Sea Water Connection in Engine Systems

This part is integral to the operation of marine engine cooling systems. This component facilitates the flow of sea water into the heat exchanger, where it plays a key role in dissipating heat generated by the engine.

Interaction with the Heat Exchanger

The Sea Water Connection interfaces directly with the heat exchanger. As sea water enters through this connection, it absorbs heat from the engine coolant circulating within the exchanger’s tubes. This heat transfer is essential for maintaining optimal engine operating temperatures.

Contribution to Engine Cooling System

In the broader context of the engine cooling system, the Sea Water Connection ensures a continuous supply of cool sea water. This is particularly important in marine environments where ambient air cooling is less effective. The efficient circulation of sea water through the heat exchanger prevents engine overheating, which can lead to reduced performance and potential damage.

Ensuring System Efficiency

The design of the Sea Water Connection allows for a high flow rate of sea water, which is necessary for effective heat exchange. This component must be securely fitted to avoid leaks, which could compromise the cooling efficiency and lead to engine strain. Regular maintenance and inspection of the Sea Water Connection are recommended to ensure the longevity and reliability of the engine cooling system.

Conclusion

The Sea Water Connection 3008816 by Cummins is a critical component for marine engines, ensuring efficient thermal management and preventing overheating. Its robust construction, precise engineering, and integration with the heat exchanger make it a reliable and essential part of the engine cooling system. Regular maintenance and proper installation are key to maximizing its performance and longevity.

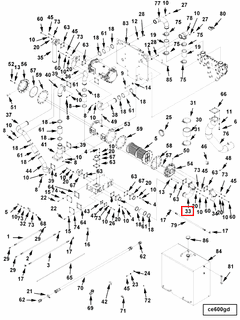

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.