This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

The Sea Water Connection 3008815, manufactured by Cummins, is a critical component in the cooling systems of commercial trucks and marine engines. This part is engineered to facilitate the intake of sea water, which serves as a coolant to absorb heat from the engine, ensuring optimal engine temperature and efficient operation 1.

Basic Concepts of Sea Water Connection

Sea water connections are vital for the cooling systems of marine and heavy-duty truck engines. They enable the intake of sea water, which is used as a coolant to absorb heat from the engine. This process is essential for dissipating excess heat, preventing engine overheating, and ensuring efficient engine operation. The sea water connection acts as a conduit, allowing sea water to flow into the engine’s cooling system and be expelled after heat exchange 2.

Purpose of the 3008815 Sea Water Connection

The 3008815 Sea Water Connection is designed to integrate into the engine cooling system of a truck or marine engine. Its primary function is to allow sea water to enter the system, where it absorbs heat from the engine components. This part ensures a consistent flow of coolant, which is crucial for maintaining engine temperature within safe limits. By effectively managing heat, the 3008815 contributes to the overall performance and longevity of the engine 1.

Key Features

The 3008815 Sea Water Connection is characterized by its robust design and the use of high-quality materials. It is engineered to withstand the corrosive nature of sea water, ensuring durability and reliability. The connection is designed for easy installation and maintenance, featuring a secure fitting mechanism that prevents leaks and ensures efficient coolant flow 2.

Benefits

The use of the 3008815 Sea Water Connection offers several advantages. It enhances cooling efficiency by ensuring a steady supply of coolant to the engine. This part is reliable, reducing the risk of engine overheating and potential damage. Additionally, its durable construction can lead to cost savings for fleet operators by minimizing the need for frequent replacements or repairs 1.

Installation Considerations

Proper installation of the 3008815 Sea Water Connection is crucial for its effective operation. It is recommended to follow the manufacturer’s guidelines, which may include specific prerequisites and the use of certain tools. Ensuring a secure and effective fit is important to prevent leaks and maintain the integrity of the cooling system 2.

Troubleshooting Common Issues

Common issues with the 3008815 Sea Water Connection may include leaks or blockages. Diagnostic steps should involve inspecting the connection for signs of wear or damage and ensuring that it is securely fitted. Solutions may range from tightening connections to replacing the part if it is found to be faulty 1.

Maintenance Tips

Routine maintenance of the 3008815 Sea Water Connection is important for its longevity. This includes regular inspections for signs of corrosion or damage, cleaning to remove any buildup that may obstruct coolant flow, and following the manufacturer’s guidelines for replacement intervals. Proper maintenance ensures the continued efficient operation of the engine cooling system 2.

Cummins Overview

Cummins is a renowned manufacturer in the commercial truck and marine engine industries, known for its wide range of high-quality engine and component products. With a strong reputation for reliability and performance, Cummins has been a trusted name among fleet operators for many years. The company’s commitment to innovation and customer satisfaction is reflected in its product offerings, including the 3008815 Sea Water Connection 1.

Sea Water Connection for Cummins Engines

The Sea Water Connection part 3008815 is a critical component in the cooling systems of various Cummins marine engines. This part is essential for maintaining optimal engine performance by facilitating the flow of seawater through the engine’s cooling system.

K38 Engines

In the K38 series engines, the Sea Water Connection part 3008815 is designed to integrate seamlessly with the engine’s architecture. This connection ensures that seawater is efficiently channeled into the engine’s cooling system, which is crucial for dissipating heat generated during operation. The design of this part is optimized to handle the specific flow rates and pressures associated with the K38 engines, ensuring reliable performance in marine environments 2.

K50 Engines

Similarly, for the K50 series engines, the Sea Water Connection part 3008815 plays a pivotal role in the cooling process. The K50 engines, known for their robust performance, require a dependable connection to maintain the integrity of the cooling system. This part is engineered to withstand the demanding conditions of marine operations, providing a secure and efficient pathway for seawater to flow through the engine 2.

Grouping Considerations

While the Sea Water Connection part 3008815 is specifically designed for the K38 and K50 engines, it is important to note that similar components may be used across different engine models within the Cummins marine engine range. The design and functionality of this part are tailored to meet the specific needs of each engine series, ensuring compatibility and performance across various applications 2.

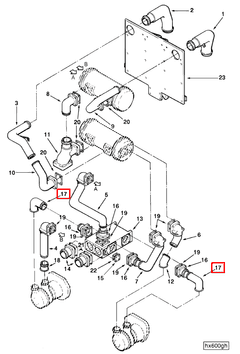

Role of Part 3008815 Sea Water Connection in Engine Systems

The part 3008815 Sea Water Connection is an essential component in various marine engine systems, facilitating the interaction between several key components and the raw water supply.

Interaction with the Drive

In marine propulsion systems, the drive unit often requires cooling to maintain optimal performance and longevity. The Sea Water Connection ensures a steady flow of raw water to the drive, allowing for efficient heat dissipation. This consistent water flow helps in maintaining the drive’s temperature within safe operational limits, thereby enhancing its reliability and durability 1.

Contribution to Fan Operation

While fans in marine engines are typically air-cooled, the Sea Water Connection indirectly supports their operation by ensuring the overall engine system remains cool. By maintaining lower ambient temperatures around the engine components, the fan can operate more effectively, contributing to the engine’s thermal management system 1.

Integration with the Pump

The pump within a marine engine system relies on a consistent water supply to function correctly. The Sea Water Connection provides this essential raw water flow to the pump, enabling it to circulate coolant throughout the engine. This circulation is vital for dissipating heat generated by the engine’s operation, ensuring the pump and other components remain within their optimal temperature range 2.

Raw Water Supply

The primary function of the Sea Water Connection is to supply raw water to the engine system. This raw water is used for cooling various components, including the engine block, exhaust manifolds, and intercoolers (if present). The consistent supply of cool seawater is fundamental to the engine’s cooling system, preventing overheating and potential damage to critical components 1.

Conclusion

The 3008815 Sea Water Connection plays a significant role in maintaining the efficiency and reliability of marine engine systems by ensuring a consistent supply of raw water to essential components such as the drive, fan, and pump. Its robust design, durability, and ease of maintenance make it a critical component for the cooling systems of Cummins engines, contributing to the overall performance and longevity of the engine 12.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.