This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

The Cummins Deaerator Connection, part number 204531, is a specialized component designed for use in heavy-duty trucks. Its purpose is to facilitate the removal of air and non-condensable gases from the coolant system, thereby enhancing the overall efficiency and reliability of the truck’s engine cooling system.

Basic Concepts of Deaerator Connection

A deaerator connection is a component that allows for the venting of air and other non-condensable gases from a liquid cooling system. In the context of a truck’s engine, it ensures that the coolant remains free of air pockets, which can impede heat transfer and lead to overheating. The deaerator connection operates on the principle that by providing a pathway for gases to escape, the coolant can maintain optimal thermal properties 1.

Purpose of Deaerator Connection 204531

The Deaerator Connection 204531 plays a specific role in the truck’s cooling system by enabling the efficient removal of air and non-condensable gases from the coolant. This function is vital for maintaining the coolant’s ability to transfer heat away from the engine, thus supporting consistent engine performance and longevity.

Key Features

The Deaerator Connection 204531 is characterized by its robust design and the use of high-quality materials that ensure durability and reliable performance. Its construction includes features that facilitate easy installation and integration with the truck’s existing cooling system. Additionally, the connection is designed to withstand the high temperatures and pressures typical of heavy-duty truck engines.

Benefits

Incorporating the Deaerator Connection 204531 into a truck’s cooling system offers several advantages. It contributes to improved engine efficiency by ensuring that the coolant system operates without air interference. This results in more effective heat dissipation and can lead to reduced maintenance needs. Furthermore, the enhanced reliability of the cooling system supports the overall performance and durability of the truck 2.

Installation Process

Installing the Deaerator Connection 204531 requires careful attention to ensure proper integration with the truck’s cooling system. The process involves preparing the installation site, which may include cleaning and inspecting the area for any damage. The connection should be securely fastened according to the manufacturer’s guidelines, using the appropriate tools to ensure a leak-free seal.

Common Issues and Troubleshooting

Typical problems associated with the Deaerator Connection 204531 may include leaks or blockages. Troubleshooting these issues involves inspecting the connection for signs of wear or damage and ensuring that it is correctly installed. Addressing these problems promptly can prevent more significant issues within the cooling system.

Maintenance Tips

Regular maintenance of the Deaerator Connection 204531 is key to ensuring its longevity and optimal performance. This includes periodic inspections for signs of wear or corrosion, ensuring that all connections are secure, and verifying that the cooling system is free of contaminants. Adhering to these maintenance practices can help prevent unexpected failures and extend the component’s service life.

Cummins Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. With a rich history of innovation and a broad product range, Cummins is renowned for its quality and reliability in the automotive industry, particularly in the segment of heavy-duty truck components. The company’s commitment to excellence and customer satisfaction has established it as a trusted name in the field.

Cummins Deaerator Connection Part 204531 in Engine Applications

The Cummins Deaerator Connection part number 204531 is a critical component in the engine’s cooling system, specifically designed to interface with the deaerator. This part ensures that the engine’s cooling system operates efficiently by facilitating the removal of dissolved gases, which can otherwise lead to corrosion and other issues within the engine’s cooling system.

Integration with N14 Mechanical Engines

In the N14 Mechanical engine series, the Deaerator Connection part 204531 plays a pivotal role in maintaining the integrity of the engine’s cooling system. This part is engineered to seamlessly integrate with the engine’s design, ensuring that it can effectively connect to the deaerator and perform its function without any issues. The precise fit and compatibility of this part with the N14 Mechanical engine series ensure that the engine can operate at optimal efficiency, with minimal risk of cooling system failures.

Compatibility and Functionality

The Cummins Deaerator Connection part 204531 is designed to be compatible with various Cummins engine models, ensuring that it can be used across different engine series. This compatibility is achieved through rigorous testing and design processes, which ensure that the part can fit and function correctly within the engine’s cooling system. The part’s design allows it to effectively connect to the deaerator, facilitating the removal of dissolved gases and maintaining the overall health of the engine’s cooling system.

Importance in Engine Performance

The proper functioning of the Deaerator Connection part 204531 is crucial for the overall performance and longevity of the engine. By ensuring that dissolved gases are effectively removed from the cooling system, this part helps to prevent corrosion and other issues that can lead to engine failures. This is particularly important in high-performance engines like the N14 Mechanical series, where the cooling system is under constant stress and needs to operate at peak efficiency.

Installation and Maintenance

Installing the Cummins Deaerator Connection part 204531 is a straightforward process, thanks to its precise design and compatibility with various engine models. Regular maintenance of this part is essential to ensure that it continues to function correctly and prevent any potential issues within the engine’s cooling system. Technicians should inspect the part for any signs of wear or damage during routine maintenance checks and replace it if necessary to ensure the engine’s continued optimal performance.

Role of Part 204531 Deaerator Connection in Engine Systems

The Deaerator Connection, identified by part number 204531, is an integral component within various engine systems, ensuring optimal performance and longevity. Its primary function is to facilitate the removal of air and dissolved gases from the lubricating oil, which is essential for maintaining the efficiency and reliability of the engine.

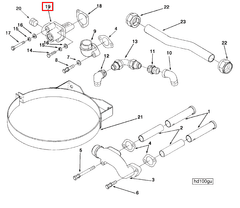

Integration with Lubricating Systems

In the context of lubricating systems, the Deaerator Connection is strategically positioned to interact with several key components. It is mounted using the Deaerator Connection Mounting and Deaerator Mounting brackets, which secure it firmly in place within the engine bay. This mounting ensures that the Deaerator Connection remains stable and operates efficiently under varying engine conditions.

The Deaerator Connection is directly linked to the Lubricating Oil Plumbing, which is responsible for circulating oil throughout the engine. By integrating with this plumbing system, the Deaerator Connection helps to maintain a consistent flow of deaerated oil, which is vital for reducing wear on moving parts and enhancing overall engine performance.

Interaction with the Lubricating Pump

Another significant interaction occurs with the Lubricating Pump Plumbing. The Deaerator Connection works in tandem with the lubricating pump to ensure that the oil delivered to various engine components is free from air bubbles and contaminants. This collaboration is essential for maintaining the pump’s efficiency and preventing potential damage caused by aerated oil.

Connection to the Oil Pan

The Deaerator Connection also plays a role in the Oil Pan system. It is connected to the Oil Pan, which serves as the reservoir for the engine’s lubricating oil. By ensuring that the oil within the pan is deaerated, the connection helps to maintain the quality of the oil, extending its usable life and reducing the frequency of oil changes.

Overall System Impact

In summary, the Deaerator Connection (part 204531) is a vital component that enhances the functionality of the engine’s lubricating system. Its integration with the Deaerator Connection Mounting, Deaerator Mounting, Lubricating Oil Plumbing, Lubricating Pump Plumbing, and Oil Pan ensures that the engine receives clean, deaerated oil, which is fundamental for optimal performance and durability.

Conclusion

The Cummins Deaerator Connection part 204531 is a critical component in both the cooling and lubricating systems of heavy-duty engines. Its role in removing air and dissolved gases ensures the efficiency and reliability of the engine, contributing to its overall performance and longevity. Proper installation, regular maintenance, and prompt troubleshooting of any issues are essential practices to maximize the benefits of this part.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.