This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

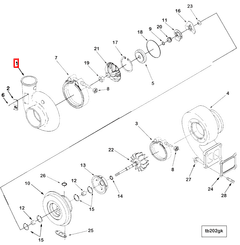

The Cummins 3537782 Compressor Housing is a component designed for use in turbocharger systems, specifically tailored for commercial trucks. It plays a role in enhancing engine performance by optimizing the turbocharger’s efficiency. This housing is integral to the operation of the turbocharger, contributing to increased engine power and efficiency in heavy-duty applications 1.

Basic Concepts of Compressor Housing

A compressor housing is a part of the turbocharger that encases the compressor wheel. Its function is to direct the flow of air into the engine, compressing it before it enters the combustion chamber. This compression increases the density of the air, allowing more oxygen to be available for combustion, which in turn enhances engine efficiency. The principles of turbocharging involve using exhaust gases to spin a turbine, which is connected to the compressor wheel. As the compressor wheel spins, it draws in and compresses air, which is then fed into the engine. The compressor housing plays a role in this process by ensuring that the compressed air is directed efficiently into the engine 2.

Purpose and Role in Truck Operation

The 3537782 Compressor Housing serves to increase air intake in the operation of a truck. By compressing the air before it enters the engine, it aids in improving combustion efficiency. This results in a boost in engine power output, allowing the truck to perform more effectively under various load conditions. The housing ensures that the compressed air is delivered smoothly and consistently, which is vital for maintaining engine performance 3.

Key Features

The Cummins 3537782 Compressor Housing is characterized by its robust design and the materials used in its construction. It is built to withstand the high pressures and temperatures associated with turbocharging in commercial trucks. The housing may feature specific design elements that enhance its performance, such as optimized airflow channels and durable construction materials that contribute to its longevity and reliability 4.

Benefits

Using the Cummins 3537782 Compressor Housing can lead to improved engine performance, as it plays a role in ensuring that the turbocharger operates at peak efficiency. This can result in increased fuel efficiency, as the engine requires less fuel to produce the same amount of power. Additionally, the enhanced durability of the housing contributes to reduced maintenance costs and longer intervals between replacements, which can be beneficial for fleet operators 5.

Installation and Integration

Proper installation of the 3537782 Compressor Housing within the turbocharger system is vital for optimal performance. It should be fitted correctly to ensure a secure and airtight connection. Alignment is also important to maintain the efficiency of the turbocharger. Following manufacturer guidelines during installation can help prevent issues and ensure that the housing functions as intended 6.

Common Issues and Troubleshooting

Compressor housings can encounter issues such as leaks, cracks, or a decline in performance over time. These issues can be identified through regular inspections and performance checks. Troubleshooting may involve checking for signs of wear or damage, ensuring all connections are secure, and verifying that the housing is free from obstructions that could impede airflow 7.

Maintenance Tips

Regular maintenance practices are recommended to ensure the longevity and efficient operation of the 3537782 Compressor Housing. This includes routine inspections for signs of wear or damage, cleaning to remove any buildup that could affect performance, and adhering to recommended replacement intervals to prevent failure 8.

Performance Enhancements

There are potential performance enhancements and upgrades that can be made in conjunction with the 3537782 Compressor Housing. These may include modifications to the turbocharger system or the use of higher-performance components that can work synergistically with the housing to further optimize engine performance 9.

Cummins Overview

Cummins Inc. is a well-established manufacturer with a significant presence in the commercial truck industry. The company has a history of innovation and a reputation for producing high-quality automotive components. Cummins’ commitment to quality is evident in the design and manufacturing of parts like the 3537782 Compressor Housing, which are engineered to meet the demanding requirements of commercial truck applications 10.

Cummins Engine Compatibility with Compressor Housing Part 3537782

The Cummins Compressor Housing part number 3537782 is designed to fit seamlessly within a range of Cummins engine models. This part is integral to the engine’s operation, ensuring optimal performance and reliability. Below is a detailed look at the compatibility of this specific part with various Cummins engines.

ISM CM570

The ISM CM570 engine benefits from the precise engineering of the 3537782 Compressor Housing. This component is crucial for maintaining the engine’s efficiency and longevity, providing the necessary compression for optimal fuel combustion.

ISM11 CM876 SN and M11 CELECT PLUS

Both the ISM11 CM876 SN and M11 CELECT PLUS engines are equipped with the 3537782 Compressor Housing, which is designed to meet the stringent demands of these high-performance engines. This part ensures that the engines operate smoothly and efficiently, contributing to their overall reliability and durability.

Compatibility Summary

The Compressor Housing part number 3537782 is a versatile component that fits well within the ISM CM570, ISM11 CM876 SN, and M11 CELECT PLUS engines. Its design ensures that it integrates smoothly with these engines, providing the necessary support and functionality for optimal engine performance.

Role of Part 3537782 Compressor Housing in Engine Systems

The Compressor Housing (part 3537782) is an integral component in the operation of an aftermarket turbocharger system. It encases the compressor wheel, which is responsible for compressing the intake air before it enters the engine’s combustion chambers. This compression increases the air density, allowing more oxygen to enter the engine, which in turn supports the combustion of a greater amount of fuel.

When integrating this compressor housing with a turbocharger kit, it is essential to ensure that it aligns perfectly with the compressor wheel and the turbine housing. The housing must be designed to withstand the high pressures and temperatures generated during operation.

In a performance turbocharger setup, the compressor housing plays a significant role in determining the airflow capacity and the boost pressure levels. A well-designed housing will facilitate efficient airflow, minimizing turbulence and pressure drops. This efficiency directly impacts the overall performance of the turbocharger, allowing for greater power output and improved engine efficiency.

Additionally, the compressor housing interacts with other parts such as the intercooler and the intake manifold. The compressed air from the housing is often routed to the intercooler to reduce its temperature, enhancing its density further. The cooled, dense air is then delivered to the intake manifold, where it mixes with fuel for combustion.

In summary, the compressor housing is a key component that ensures the efficient operation of the turbocharger, directly influencing the performance and reliability of the engine system.

Conclusion

The Cummins 3537782 Compressor Housing is a critical component in the turbocharger system of commercial trucks, designed to enhance engine performance and efficiency. Its robust design and compatibility with various Cummins engines make it a reliable choice for fleet operators. Regular maintenance and proper installation are essential to maximize its benefits and ensure optimal engine performance.

-

Robinson, A., & Livesey, A. (2006). The Repair of Vehicle Bodies Fifth Edition. Elsevier.

↩ -

Brach, R. M. (2023). SAE International’s Dictionary of Vehicle Accident Reconstruction and Automotive Safety. SAE International.

↩ -

Randall, M. (2015). Haynes Manual on Diesel Engines. Haynes Publishing.

↩ -

Cummins Inc. (n.d.). Operation and Maintenance Manual for X15 CM2350 X123B. Bulletin Number 5504509.

↩ -

Robinson, A., & Livesey, A. (2006). The Repair of Vehicle Bodies Fifth Edition. Elsevier.

↩ -

Cummins Inc. (n.d.). Operation and Maintenance Manual for X15 CM2350 X123B. Bulletin Number 5504509.

↩ -

Randall, M. (2015). Haynes Manual on Diesel Engines. Haynes Publishing.

↩ -

Cummins Inc. (n.d.). Operation and Maintenance Manual for X15 CM2350 X123B. Bulletin Number 5504509.

↩ -

Randall, M. (2015). Haynes Manual on Diesel Engines. Haynes Publishing.

↩ -

Cummins Inc. (n.d.). Operation and Maintenance Manual for X15 CM2350 X123B. Bulletin Number 5504509.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.